Fast slicing device for navel oranges

A fast, slicing technology, used in metal processing and other directions, can solve the problems of time-consuming and laborious, easy to be cut by tools, uneven slicing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

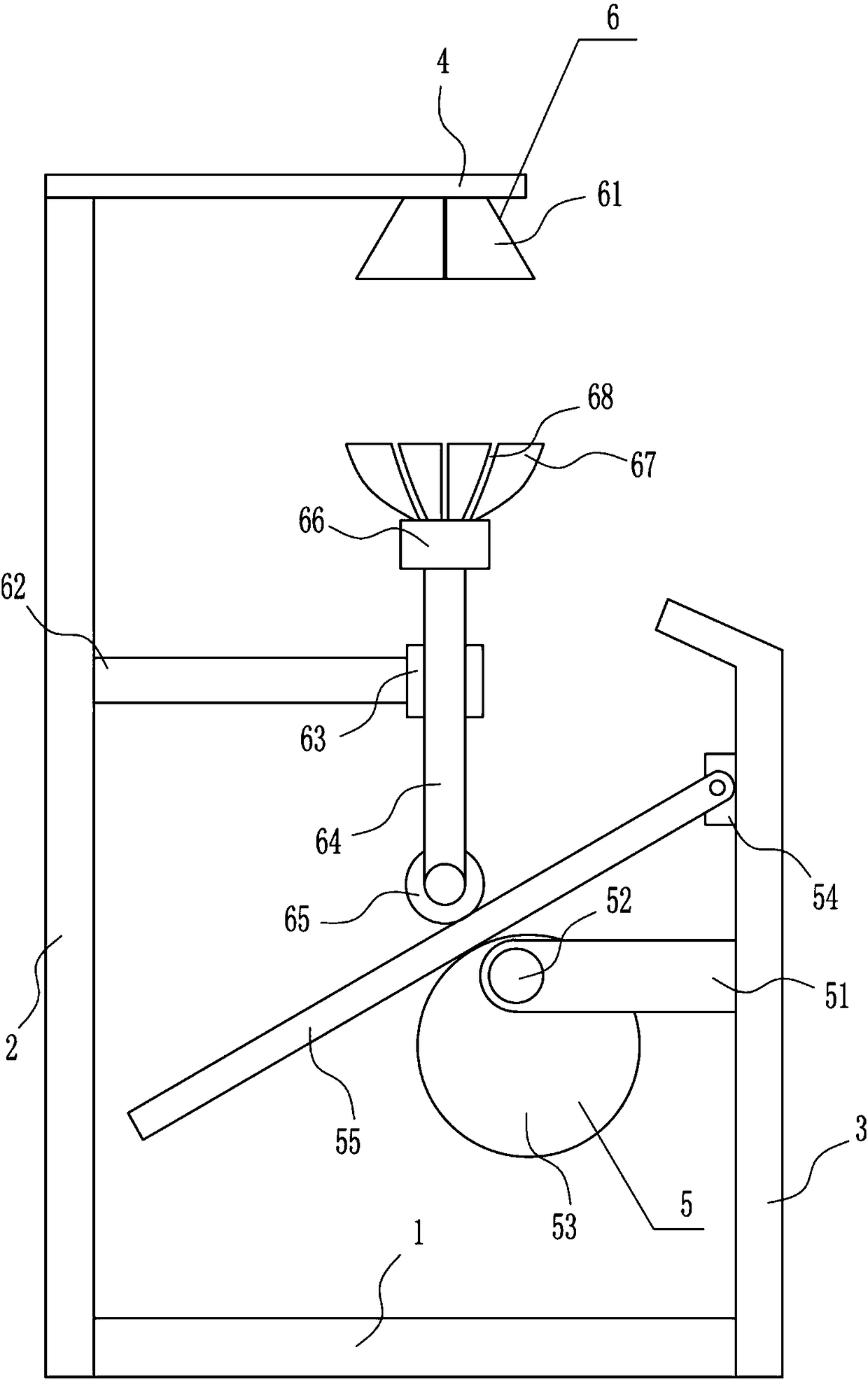

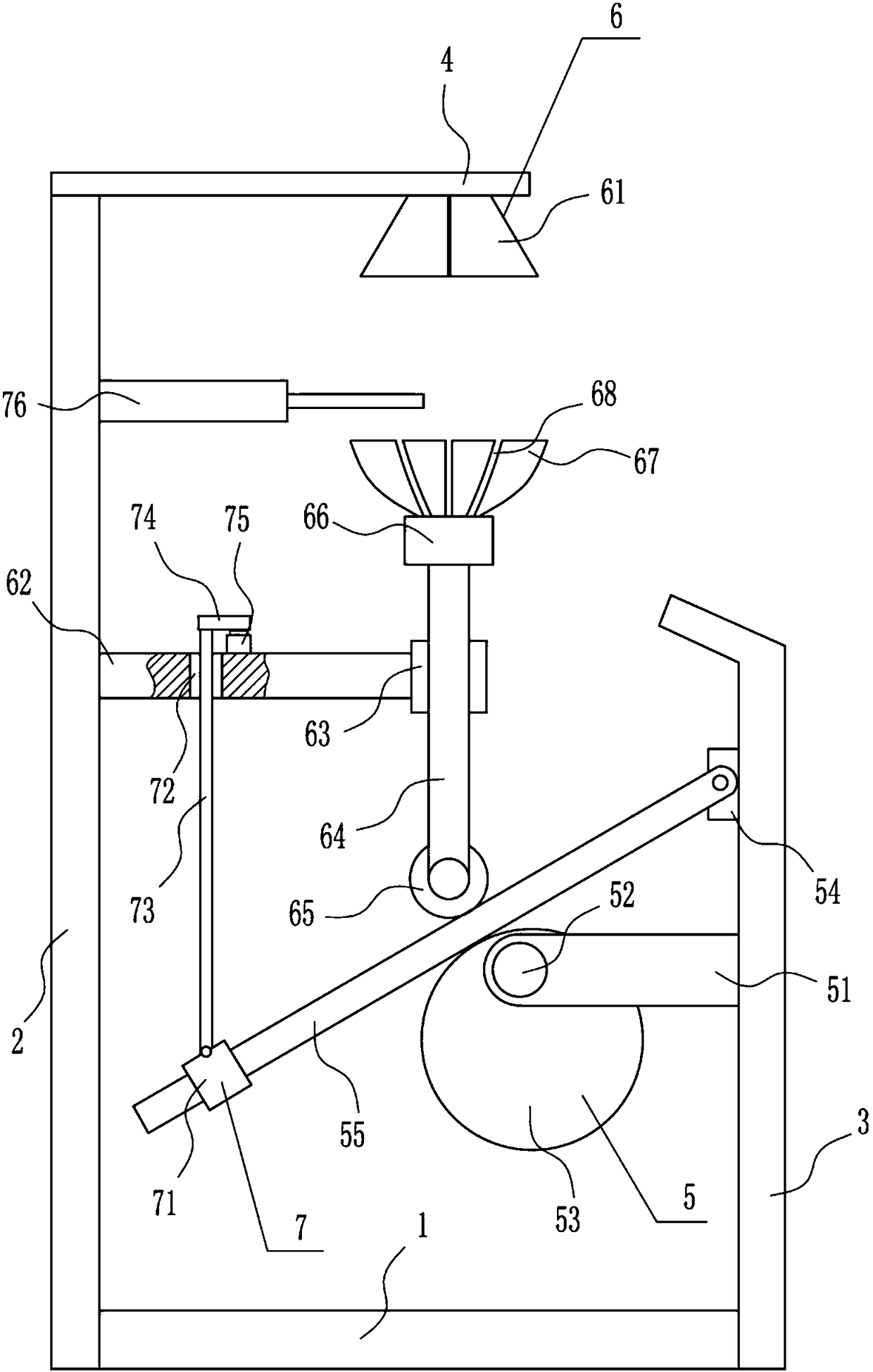

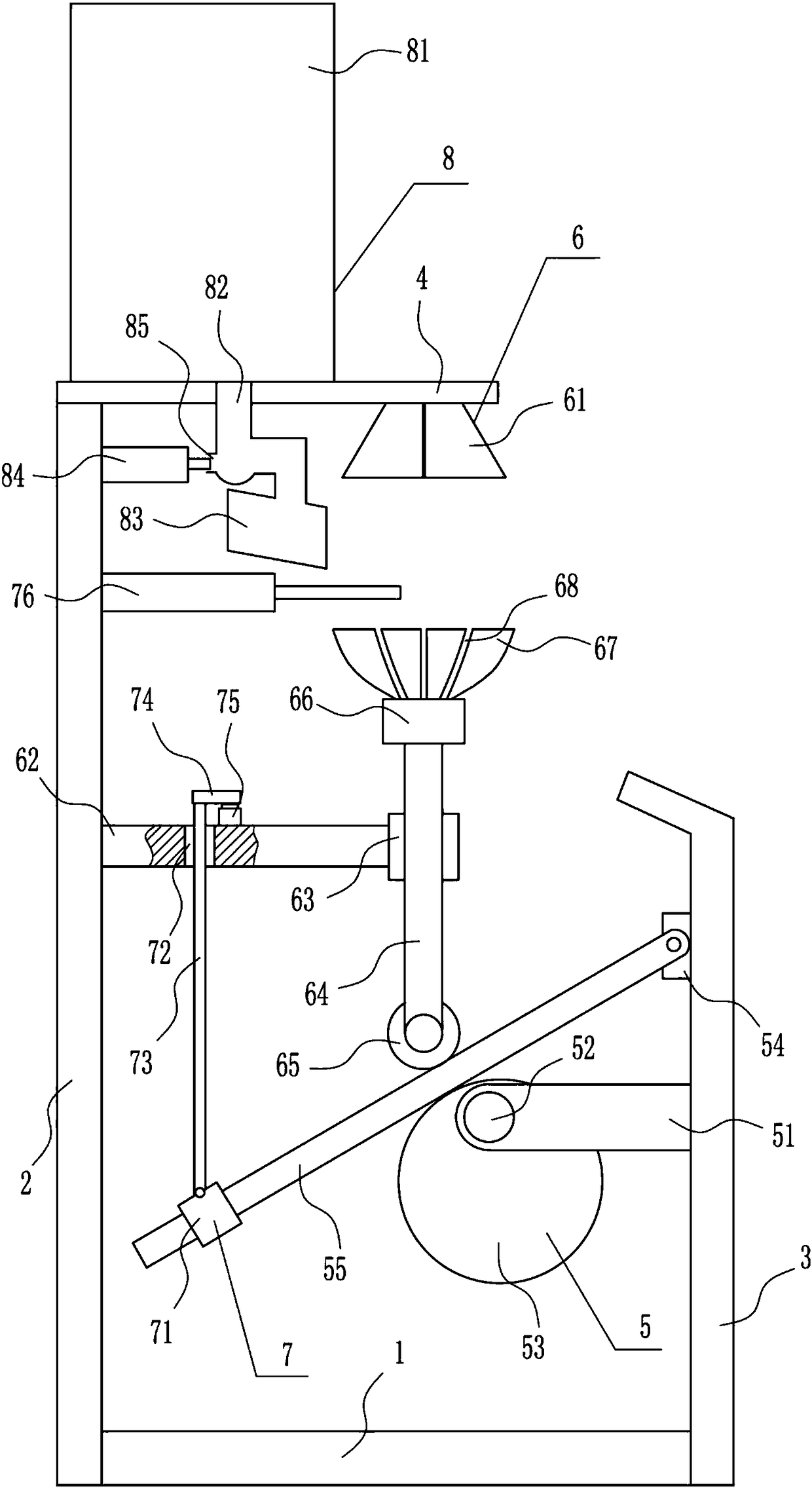

[0035] A navel orange fast slicing device, such as Figure 1-5 As shown, it includes a base plate 1, a left support 2, a right support 3, a top plate 4, a driving device 5 and a slicing device 6, a right support 3 is installed on the right side of the bottom plate 1, and a driving device 5 is provided on the left side of the right support 3. A left support 2 is installed on the left side of the bottom plate 1, and a top plate 4 is installed on the top of the left support 2. A slicing device 6 is arranged between the right side of the bottom of the top plate 4 and the left support 2, and the slicing device 6 contacts the driving device 5.

Embodiment 2

[0037] A navel orange fast slicing device, such as Figure 1-5 As shown, it includes a base plate 1, a left support 2, a right support 3, a top plate 4, a driving device 5 and a slicing device 6, a right support 3 is installed on the right side of the bottom plate 1, and a driving device 5 is provided on the left side of the right support 3. A left support 2 is installed on the left side of the bottom plate 1, and a top plate 4 is installed on the top of the left support 2. A slicing device 6 is arranged between the right side of the bottom of the top plate 4 and the left support 2, and the slicing device 6 contacts the driving device 5.

[0038] Driving device 5 comprises cross bar 51, first motor 52, eccentric cam 53, swing seat 54 and swing bar 55, and right support 3 left side middle part is equipped with cross bar 51, and cross bar 51 left end is equipped with first motor 52, The output shaft of the first motor 52 is connected with an eccentric cam 53 through a shaft coup...

Embodiment 3

[0040] A navel orange fast slicing device, such as Figure 1-5 As shown, it includes a base plate 1, a left support 2, a right support 3, a top plate 4, a driving device 5 and a slicing device 6, a right support 3 is installed on the right side of the bottom plate 1, and a driving device 5 is provided on the left side of the right support 3. A left support 2 is installed on the left side of the bottom plate 1, and a top plate 4 is installed on the top of the left support 2. A slicing device 6 is arranged between the right side of the bottom of the top plate 4 and the left support 2, and the slicing device 6 contacts the driving device 5.

[0041] Driving device 5 comprises cross bar 51, first motor 52, eccentric cam 53, swing seat 54 and swing bar 55, and right support 3 left side middle part is equipped with cross bar 51, and cross bar 51 left end is equipped with first motor 52, The output shaft of the first motor 52 is connected with an eccentric cam 53 through a shaft coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com