Shelled bamboo shoot slicing device

A slicing device and slicing technology, applied in metal processing and other directions, can solve the problems of time-consuming and laborious bamboo shoots, troublesome threading work, disorder and disorder, etc., and achieve the effect of simple structure, convenient threading work, and uniform slicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

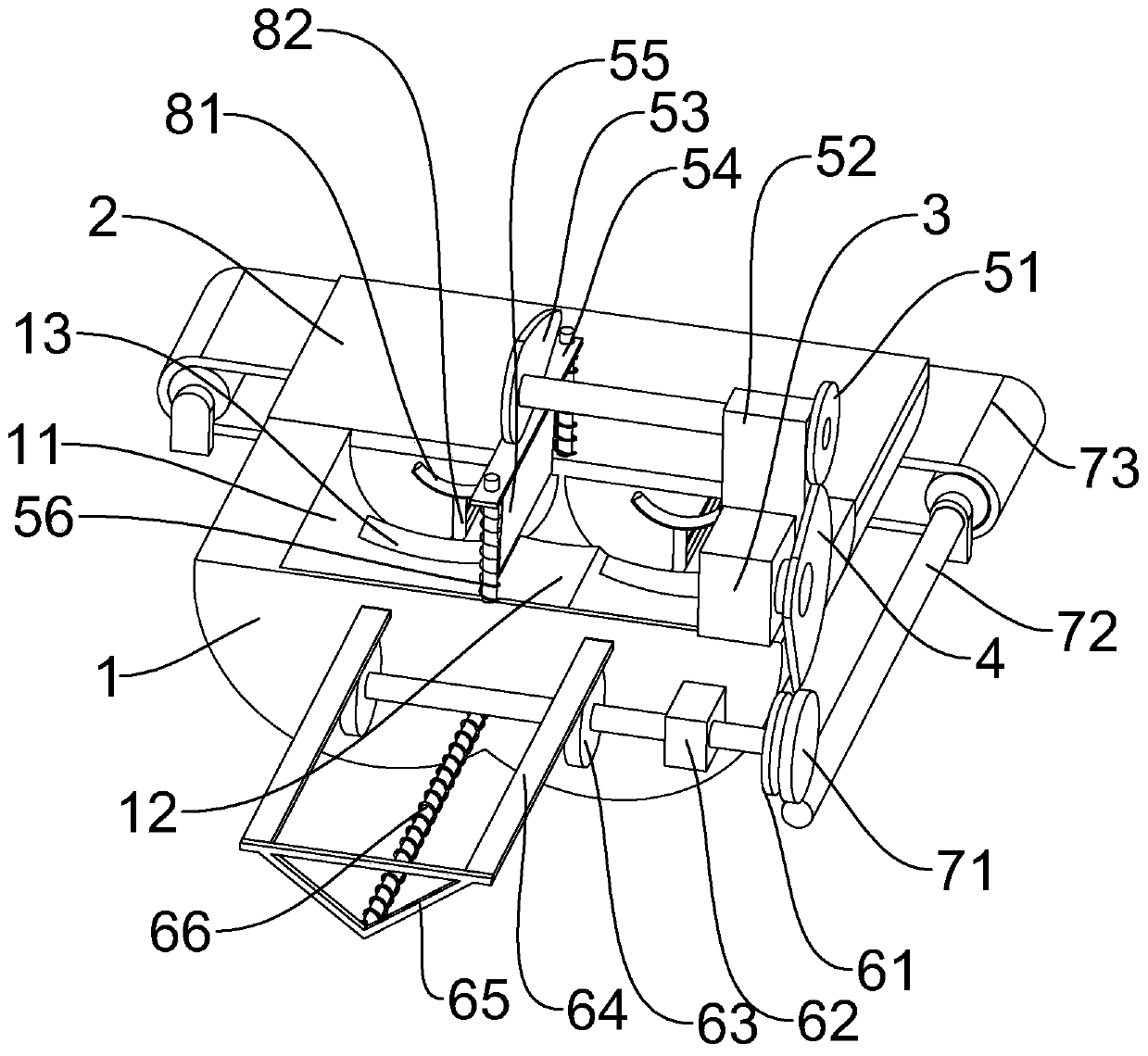

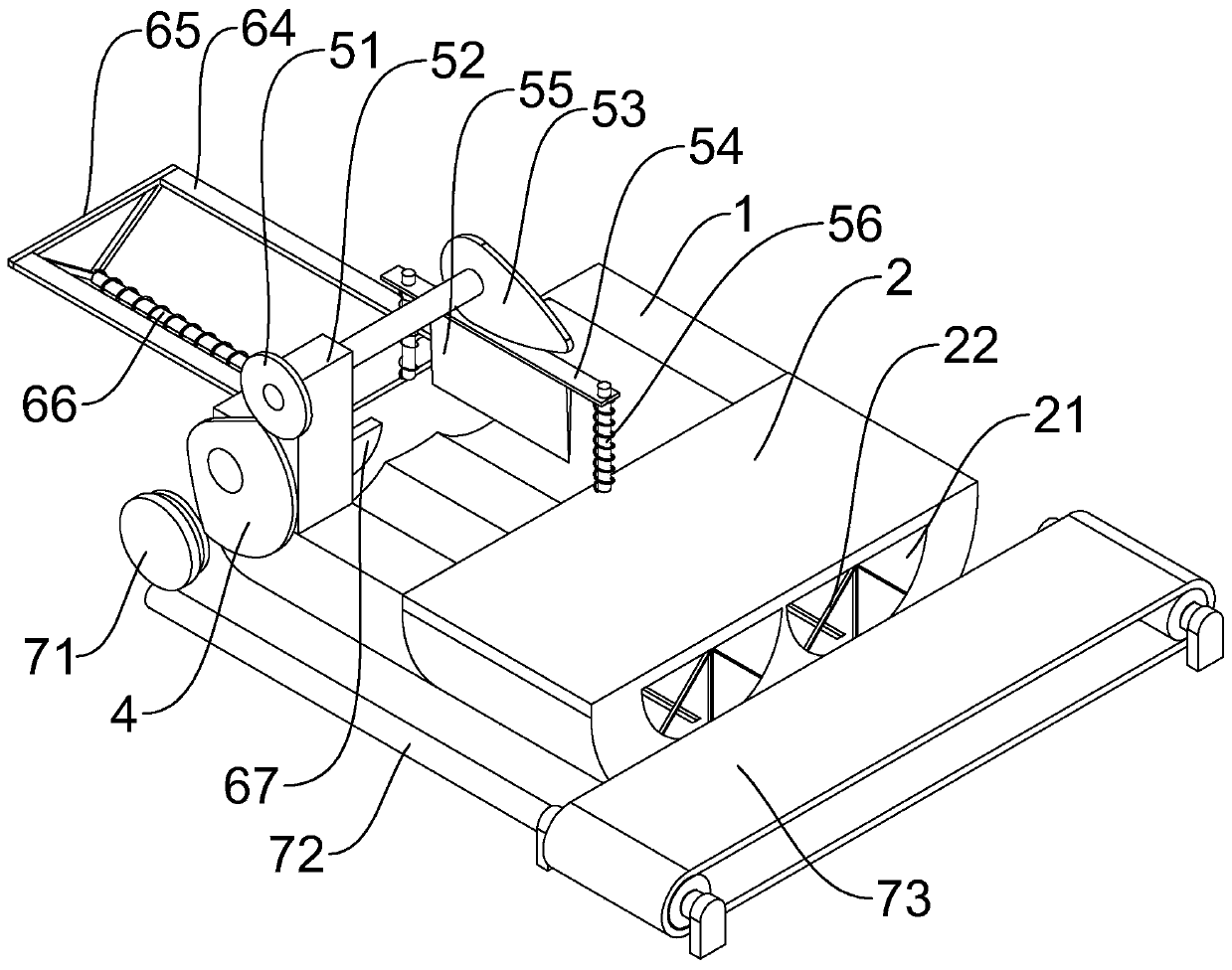

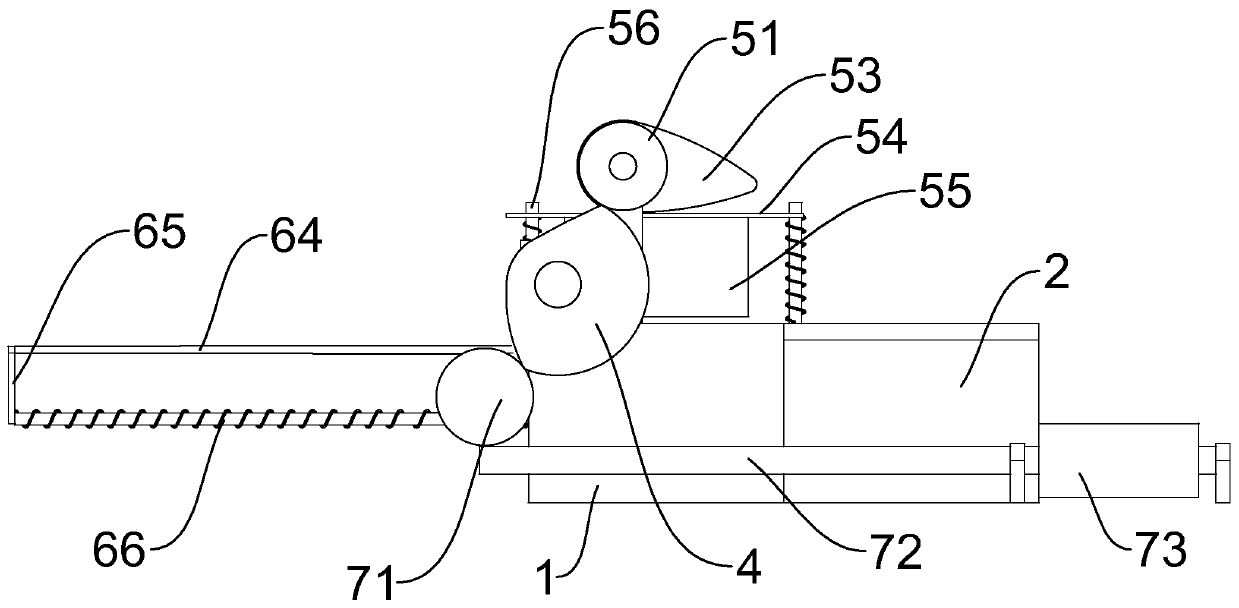

[0029] Such as Figure 1 to Figure 10 As shown, a dehulled bamboo shoot slicing device includes a breaking seat 1 and a slicing seat 2 arranged at the right end of the breaking seat 1. The front and rear ends of the breaking seat 1 are symmetrically provided with first arc-shaped grooves 11, and two first arcs A second arc-shaped groove 12 is provided in the middle of the groove 11, a semicircular hole 21 is symmetrically provided in the slicing seat 2 back and forth, a cutting piece 22 is evenly distributed on the right end of the semicircular hole 21, and the semicircular hole 21 is provided for cutting into two halves. The shelled bamboo shoots face the centering assembly 8 in the middle of the cutting piece 22. The upper end of the breaking base 1 is provided with a stepping motor 3, and the output shaft of the stepping motor 3 is keyed with an incomplete gear 4, above the incomplete gear 4 There is a breaking mechanism 5 that cooperates with the incomplete gear 4 and is us...

Embodiment 2

[0038] Improve on the basis of Example 1, such as Picture 11 As shown, the front and rear sides of the push plate 67 are symmetrically provided with extensions 68 to prevent the halved bamboo shoots from being too small and cannot be pushed when the push plate 67 moves to the right. The extension 68 can be pushed to the Open the centering assembly 8. Moreover, the conveyor belt can be appropriately extended, and then a needle is set above the conveyor belt 73, and a thread is threaded through the needle hole. The needle can be stably suspended above the conveyor belt 73 by a magnet, and the sorted bamboo shoots are moved backward on the conveyor belt 73 During the transmission process, the threading needle just passes through the bamboo shoots one by one, and the bamboo shoots will be threaded on the line in order. When the thread is full, the thread of the threaded bamboo shoots will be removed, and a new thread will be put on the threading needle. In this way, the bamboo sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com