A process method for installing rudder stock barrel in stages

A process method and the technology of the rudder barrel, which are applied in the directions of transportation and packaging, shipbuilding, ship design, etc., can solve the problems of unfavorable precision level, unfavorable integration of shell and outfitting and coating, and poor construction conditions, so as to improve the precision of shipbuilding and The effect of lean shipbuilding level, improving conditions and labor intensity, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

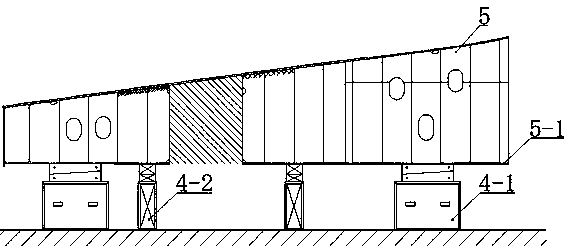

[0032] The process of installing a rudder stock barrel in stages in the present invention will be further described in detail in conjunction with the accompanying drawings, in order to understand the application process of the method of the present invention more clearly, but it cannot be used to limit the protection of the present invention. scope.

[0033] like Figure 1~Figure 6 As shown, the design method for installing the rudder stock tube in stages in this embodiment includes the following steps:

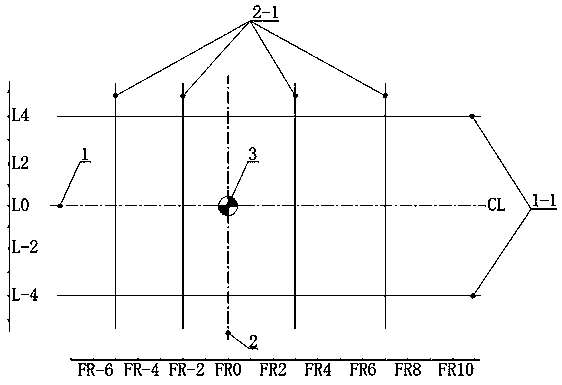

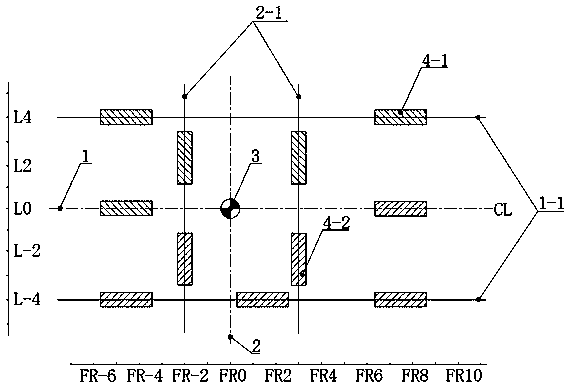

[0034] S1, surveying and delineating the datum ground line, such as figure 1 As shown, use the total station to survey and draw the hull center line 1 and FR0 rib line 2 on the floor, the marking accuracy is ±1mm, find the intersection of the hull center line 1 and FR0 rib line 2, and draw the Mark the intersection point as the center point 3 of the rudder system, take the centerline of the hull 1 as the datum line, draw the longitudinal pier layout datum line 1-1 in parall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap