Method of Installing Tied Rods of Long-span Arch Bridge

A technology for large-span arch bridges and tie rods, which is applied in the erection/assembly of bridges, bridges, and bridge construction, etc., can solve the problems of long occupation of cable cranes, poor lateral overall stability, and difficulty in foundation construction, saving temporary structures. , The construction is convenient and easy to operate, and the effect of saving temporary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0037] The invention provides a method for installing tie rods of a long-span arch bridge, the method comprising the following steps:

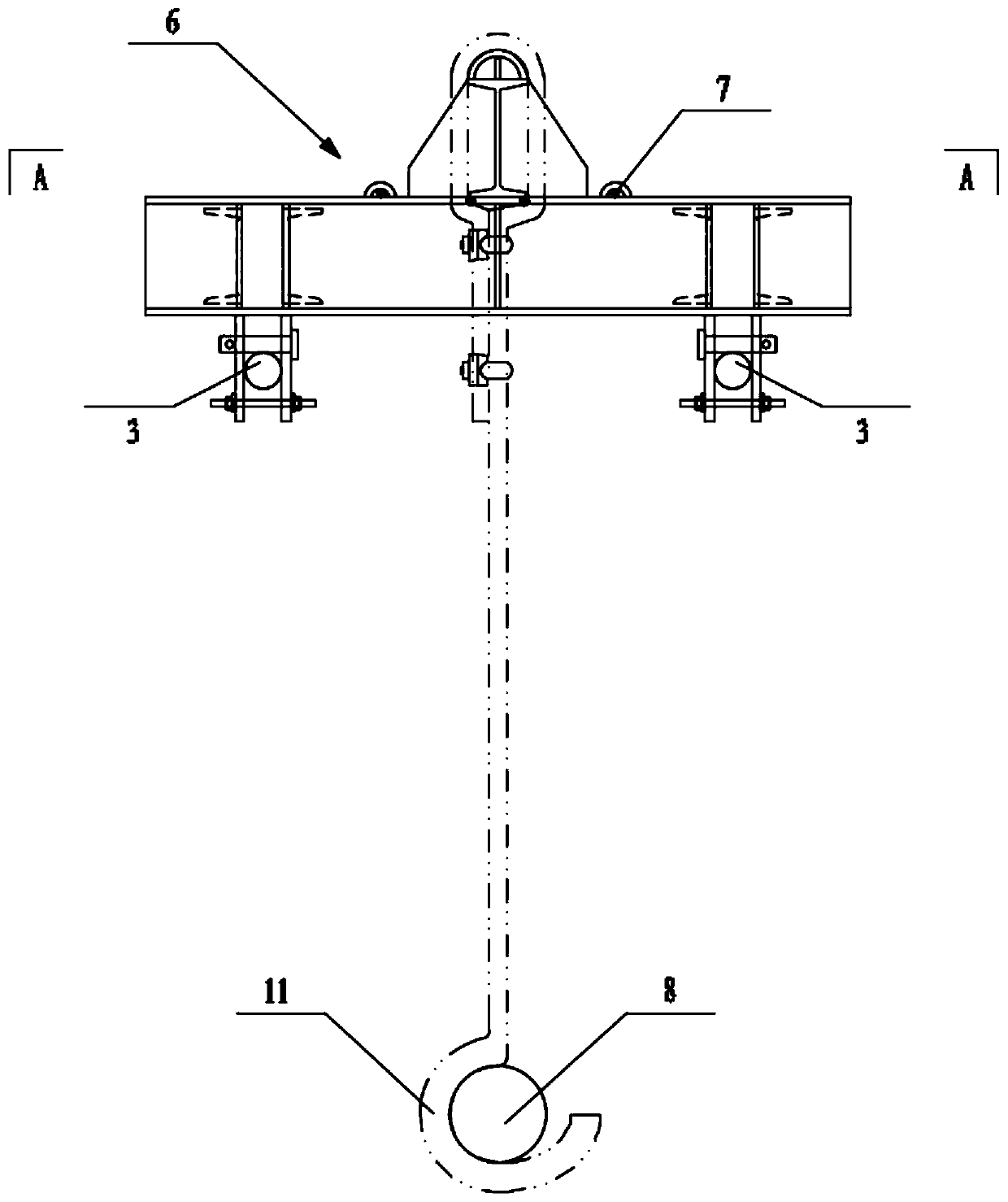

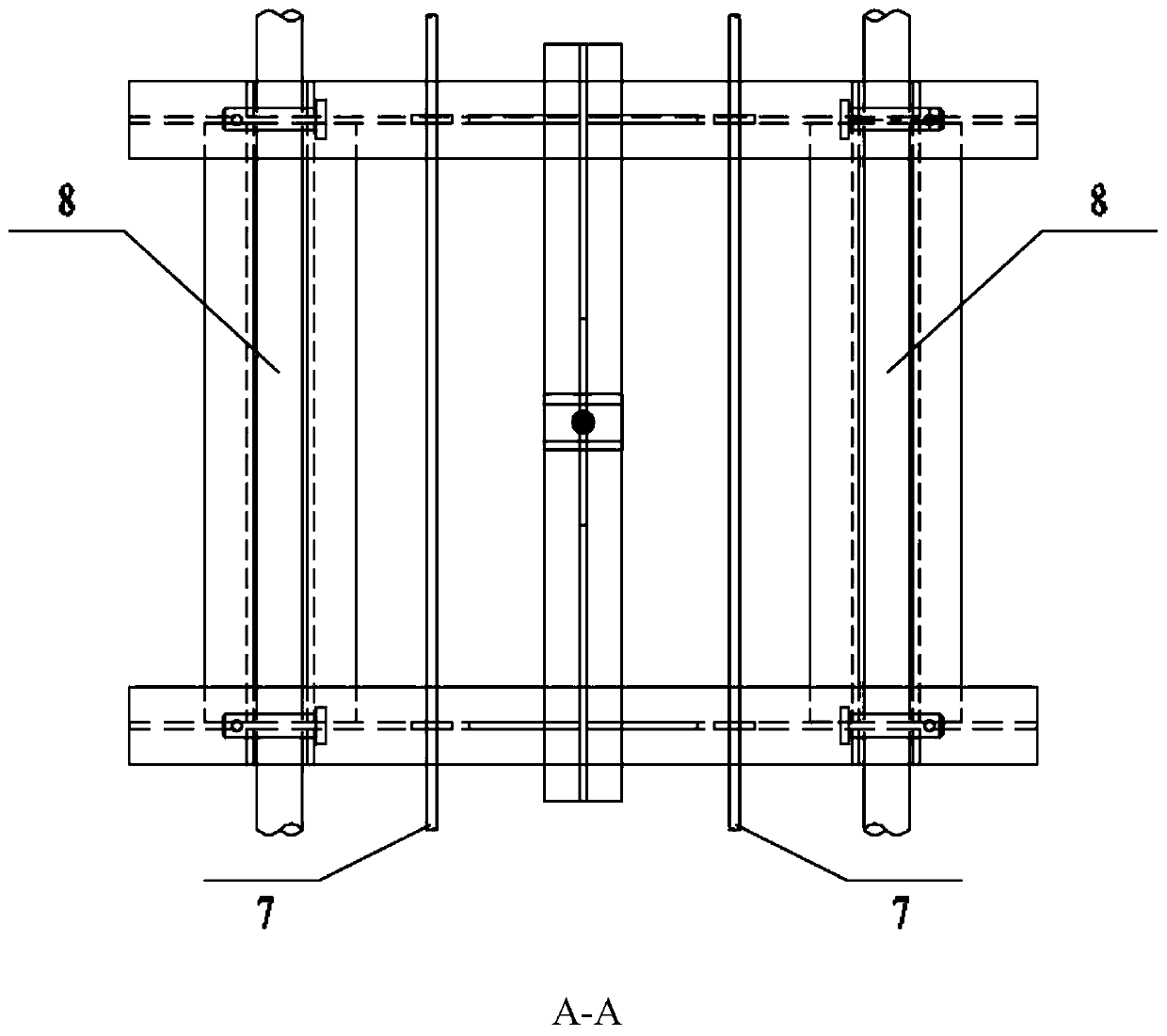

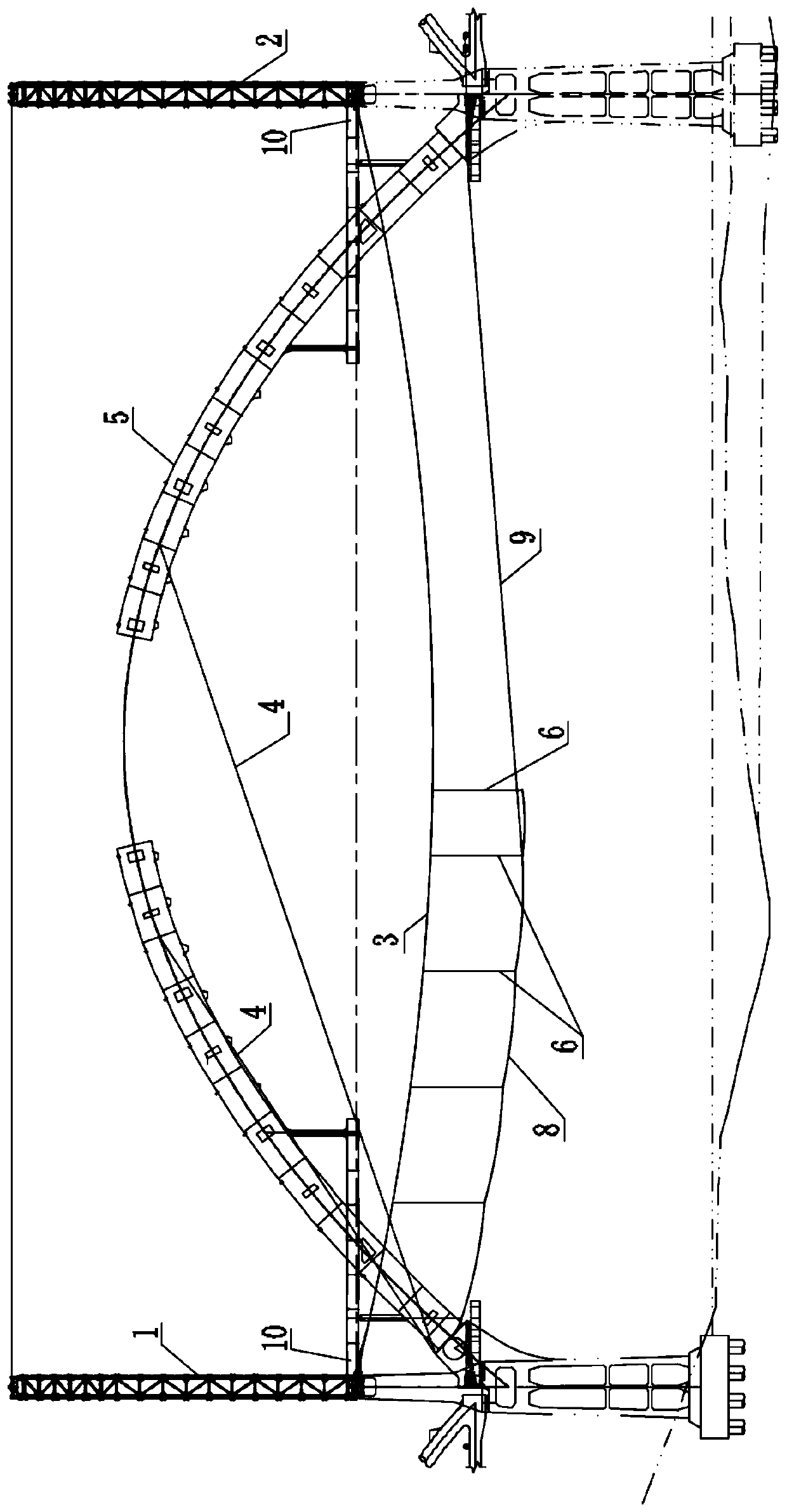

[0038] S1. Two main cables 3 arranged side by side are installed on two adjacent first buckle towers 1 and second buckle towers 2, and one end of two vertical temporary supports 4 is arranged on the arch rib 5 respectively, and the other end Temporarily anchored next to the pier of the first buckle tower 1;

[0039] Specifically, the present invention installs two main cables 3 arranged side by side on the distribution beams 10 of two adjacent first buckle towers 1 and second buckle towers 2 . The main cable 3 mainly plays a load-bearing role. Because it is directly anchored at the distribution beam 10 at the bottom of the buckle tower, the temporary structure is greatly saved, that is, the temporary material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com