A construction and installation method for steel beams in shafts

An installation method and technology of steel beams, applied in the direction of hoisting equipment safety devices, hoisting devices, etc., can solve the problems of limited space inside caverns and shafts, consume a lot of construction work time, and unfavorable wire rope protection, so as to avoid falling from high places Risk, reduce safety risk and construction difficulty, avoid frequent adjustment of direction and unsatisfactory effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

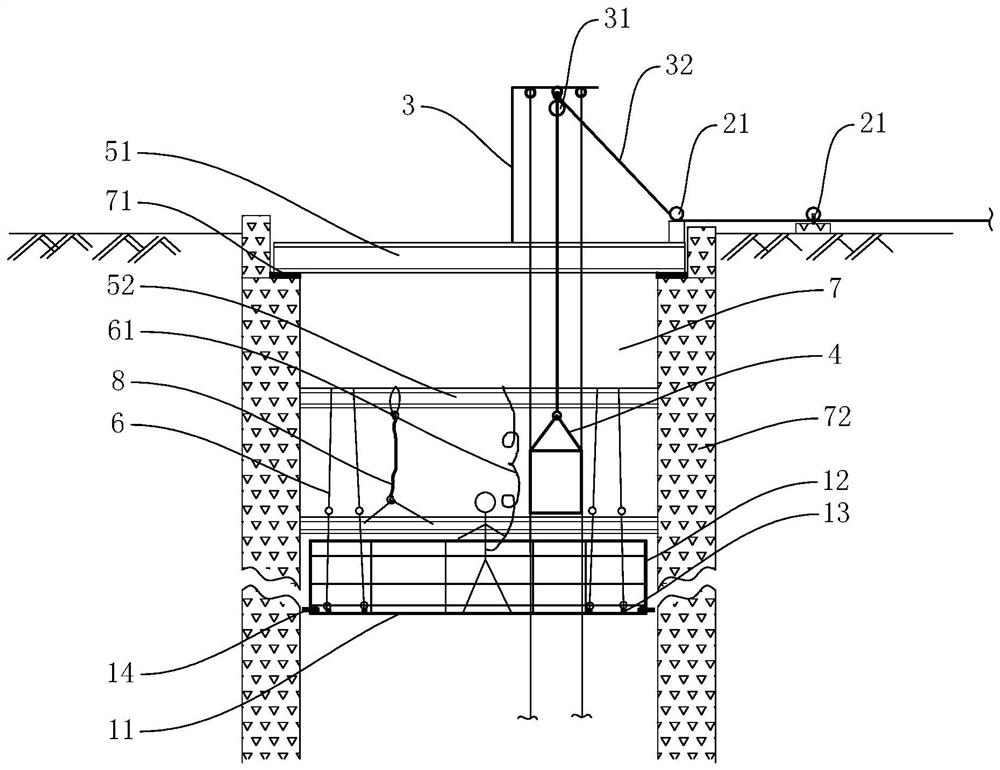

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] The construction and installation method of the steel beam in the vertical shaft of the embodiment comprises the following steps:

[0024] (1) Making steel platform for operation, see figure 1 , the working steel platform includes a base 11, a guardrail 12 and four lifting lugs 13, the guardrail 12 and the four lifting lugs 13 are respectively fixed on the upper side of the base 11, the four lifting lugs 13 are located inside the guardrail 12, and the base 11 consists of two It is formed by splicing symmetrical steel plates, and the two steel plates are connected by bolts, and the peripheral wall of the base 11 is equipped with a plurality of jacking wires 14 (at least 8);

[0025] (2) Arrange 3 winches (not shown in the figure) and multiple ground guide pulleys 21 around the shaft mouth, among which the bearing capacity of 2 winches m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com