Construction process for arched cylindrical-shaped latticed shell provided with arched steel grid jig frame by adopting slippage installation

A technology of grid tire frame and construction technology, which is applied in the direction of arch structure, dome structure, and construction material processing, etc., can solve the problems of high performance requirements of lifting equipment, occupation of scaffolding tube materials, and increased costs, etc., to achieve The effect of saving temporary materials, improving safety guarantee and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

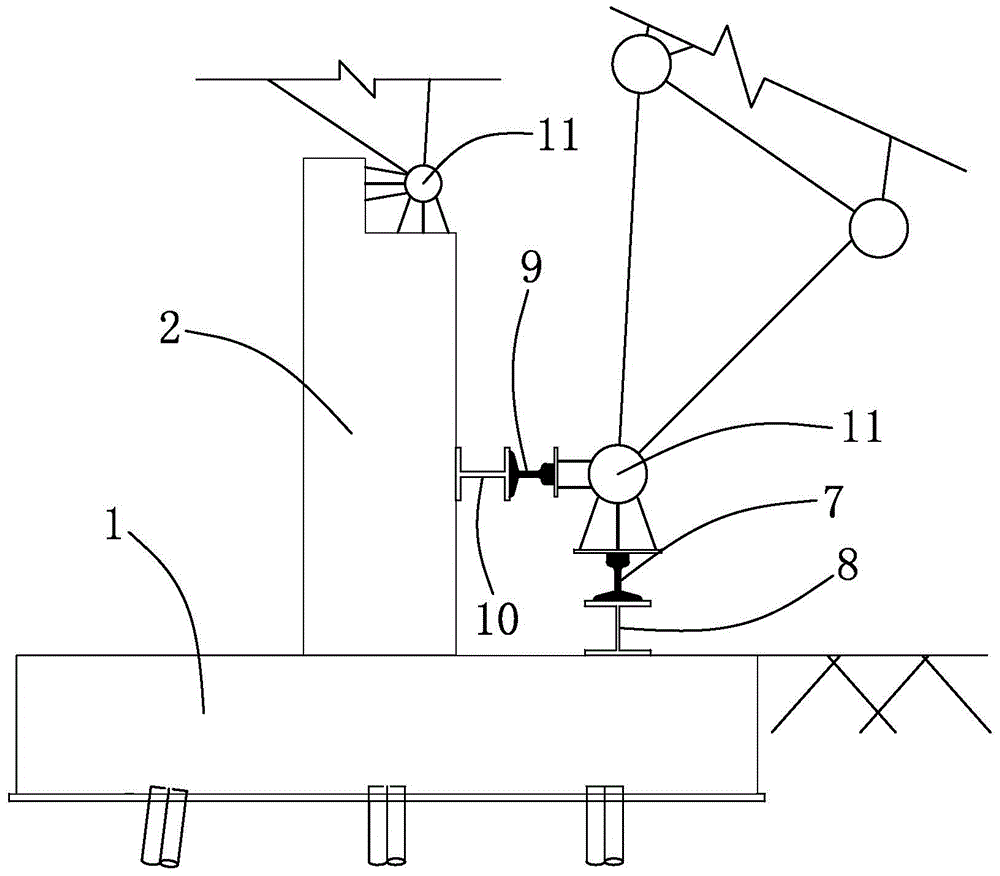

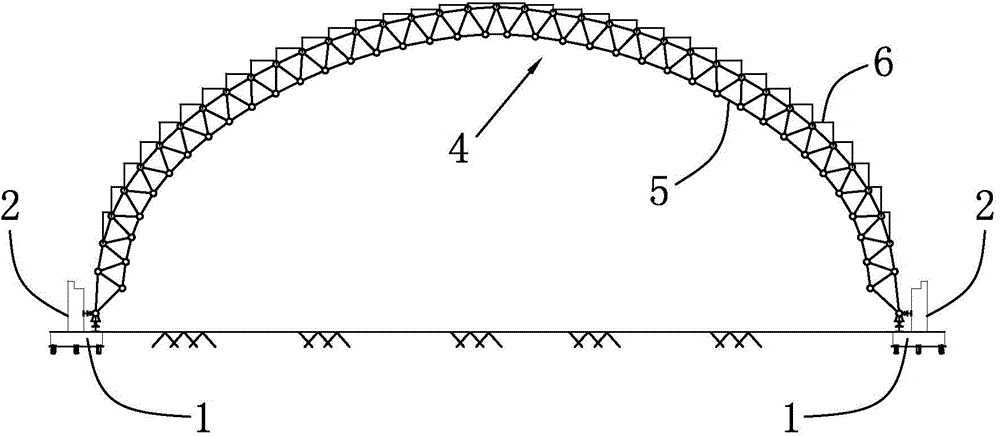

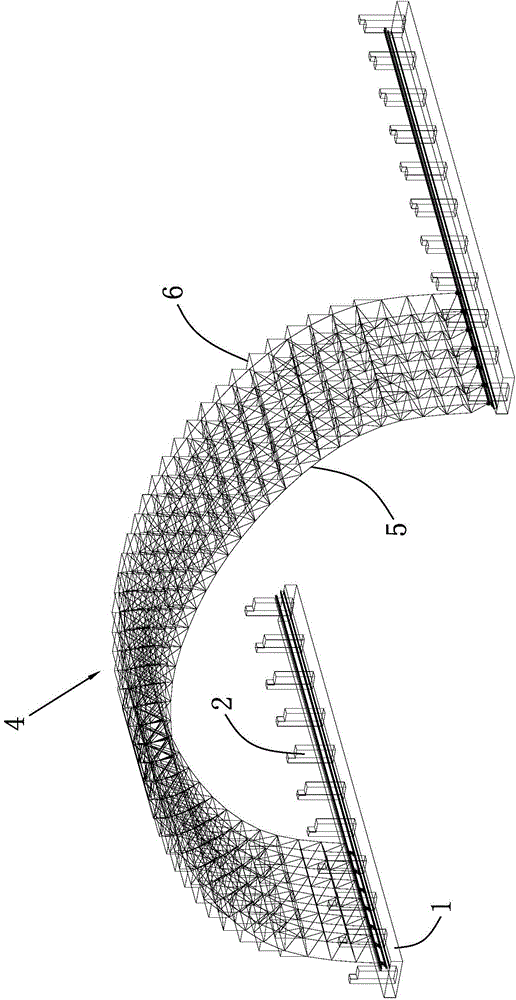

[0036] Such as Figure 1 to Figure 7 As shown, the present invention provides a kind of arched cylindrical reticulated shell construction technology with arched steel grid tire frame sliding installation, the synthesis of the advantages of various arched cylindrical reticulated shells currently used, through The reasonable setting of the arched steel grid tire frame and the technology of the sliding system tooling structure are not only conducive to improving work efficiency, shortening the construction period, saving temporary materials, reducing construction costs, and further improving safety guarantees, but also conducive to the construction of steel grid shells. During the construction of the project, the adverse impact on the simultaneous construction of other professional projects at the lower part of the steel reticulated shell was minimized, which further shortened the overall construction period and ensured that the project will be effective as soon as possible.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com