Easy-to-replace waterproof device applicable to existing railway bridge expansion joint

A technology of waterproof devices and expansion joints, which is applied to bridges, bridge parts, bridge maintenance, etc., can solve the problems of loose connection between waterproof rubber belt and section steel, accelerated corrosion of metal components of expansion joints, and short operation time of high-speed rail skylights, etc., to achieve Simple and convenient fixing, strong adaptability to stretching and deformation, and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

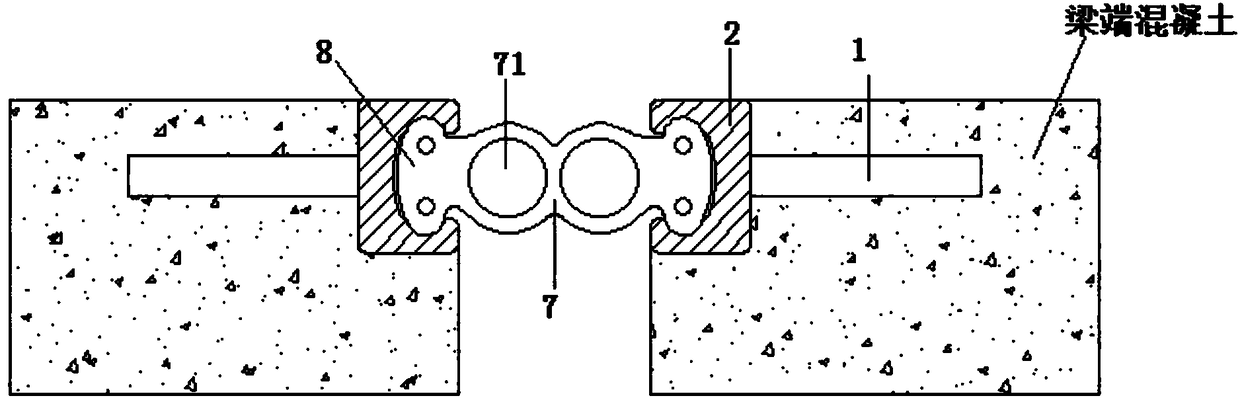

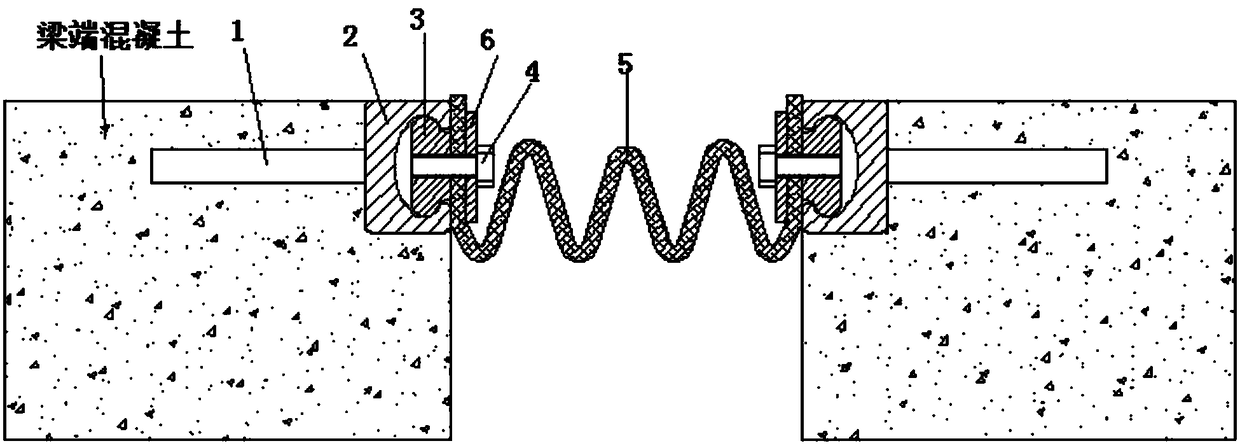

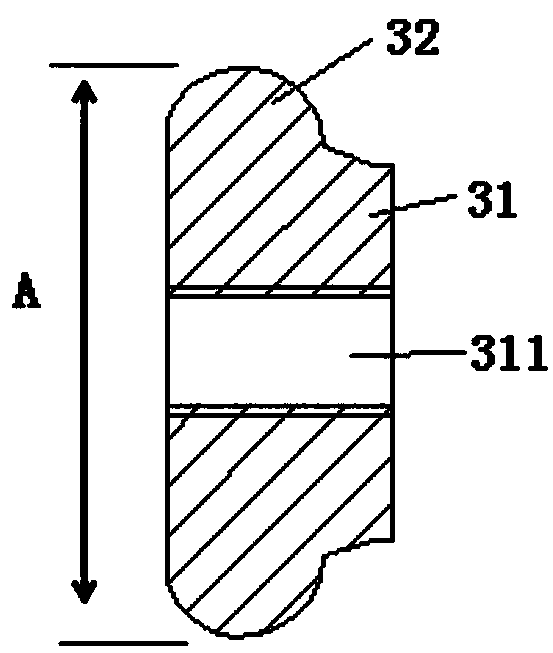

[0047] Such as figure 1As shown, the existing waterproof device includes an anchor bar 1 fixed in the concrete at the beam end on both sides, the end of the anchor bar 1 is fixed with an anchor profile steel 2, and the side walls of the two anchor profile steel 2 are all provided with installation grooves 21. The groove 21 is C-shaped, and the top and bottom of the installation groove 21 are two symmetrically arranged arc grooves; a porous waterproof rubber belt is installed and fixed between the two installation grooves 21, and the porous waterproof rubber belt includes the intermediate body 7 and The two connecting ears 8 oppositely arranged on both sides, the porous waterproof rubber belt is inlaid and clamped in the two installation grooves 21 through the connecting ears 8, and the fixing of the porous waterproof rubber belt is realized through the cooperation between the connecting ears 8 and the installation groove 21 , the end face of the intermediate body 1 has two tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com