Pressure control system used for gas gun bounce table

A technology of pressure control and impact table, which is applied in the field of mechanical environment test, can solve the problems that the impact environment cannot be simulated, and the impact resistance performance of spacecraft products cannot be truly assessed, and achieve the effect that is conducive to popularization and significant production practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

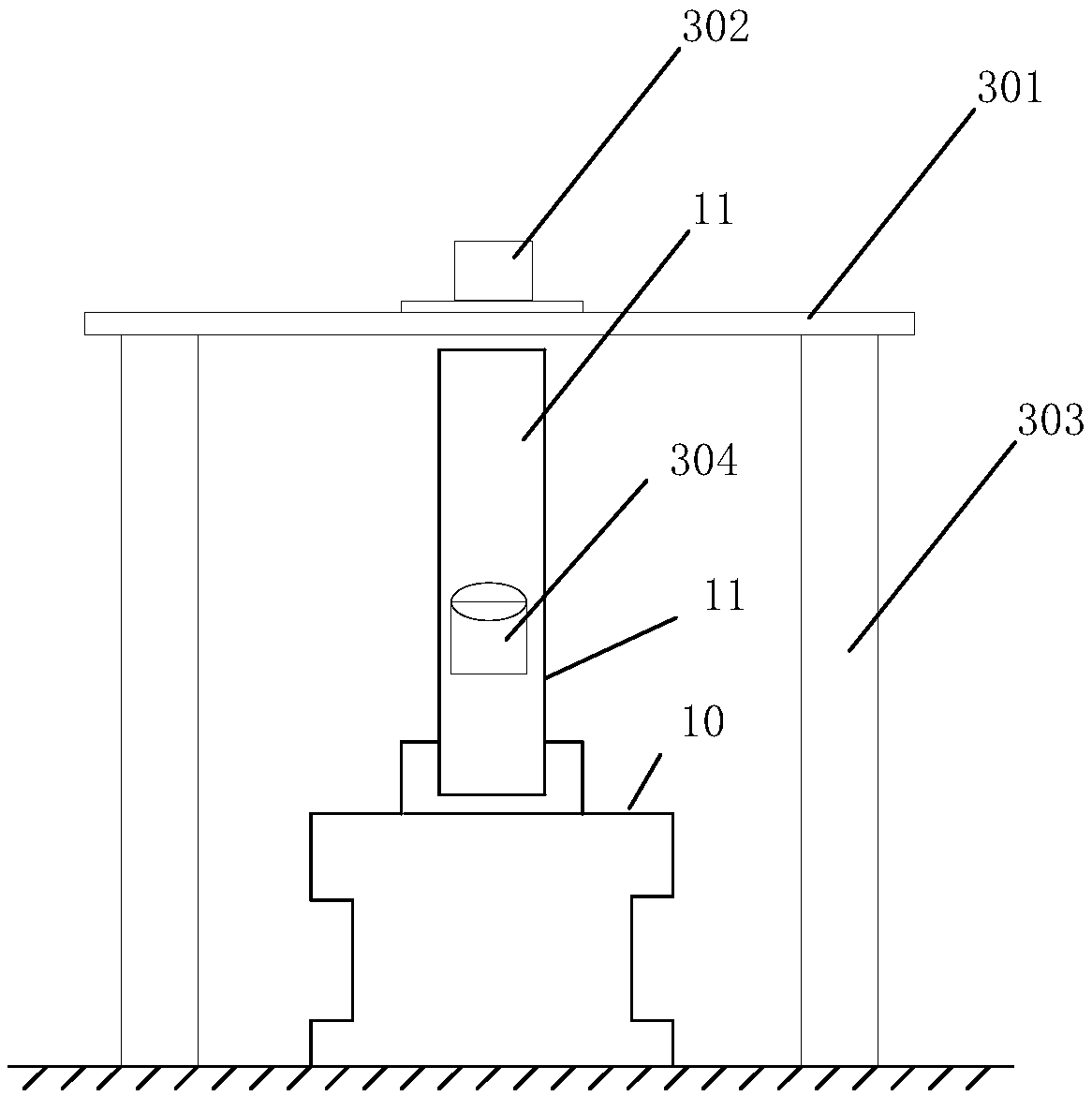

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

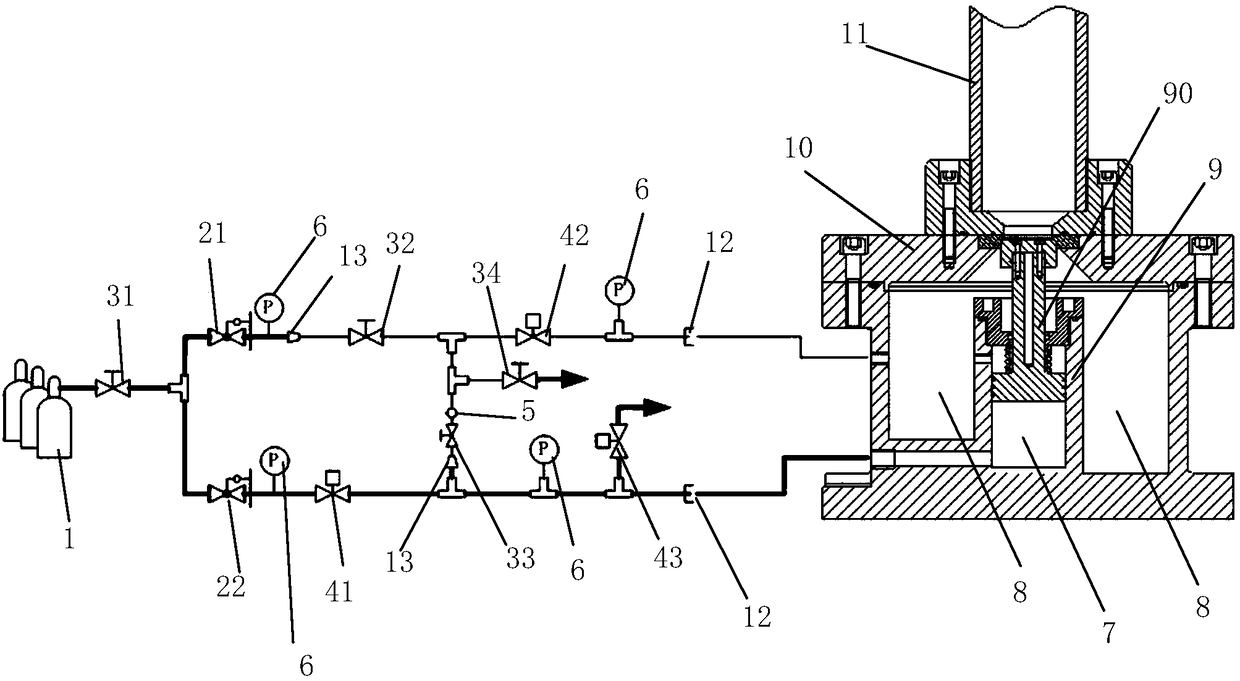

[0038] see figure 1 , the present invention provides a pressure control system for an air cannon impact platform, comprising a group of gas cylinders 1, the gas cylinders 1 are in communication with a first manual switch valve 31;

[0039] The first manual switching valve 31 communicates with the first inflation branch 100 and the second inflation branch 200 respectively;

[0040] The first inflation branch 100 communicates with the inner air chamber 7 in the air cannon impact platform, and is used for inflating the inner air chamber 7 .

[0041] The second inflation branch 200 communicates with the outer air chamber 8 in the air cannon impact platform, and is used for inflating the outer air chamber 8 .

[0042] In the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com