A Monitoring Method for Density Defects of Reinforced Sleeve Grouting Material Based on Piezoelectric Impedance Effect

A steel sleeve and piezoelectric impedance technology, applied in the direction of material impedance, can solve the problems of non-disclosure, and achieve the effects of accurate monitoring, easy operation, and small external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

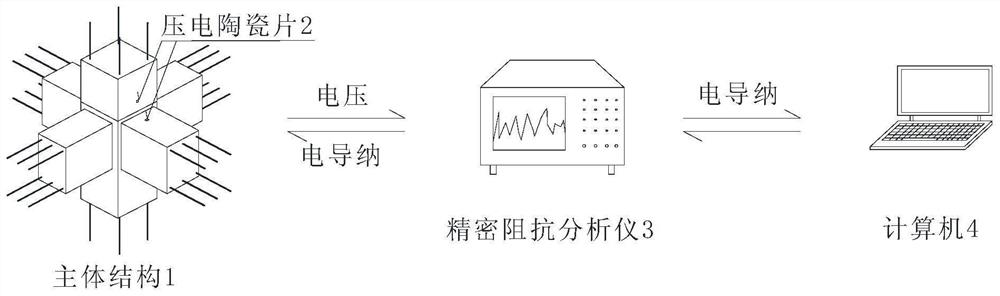

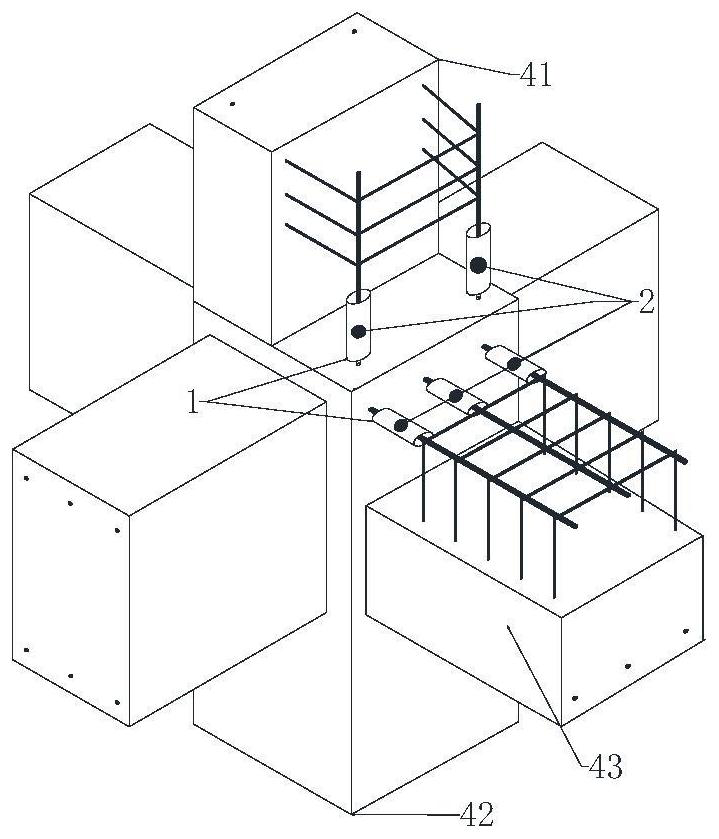

[0033] A monitoring method for the compactness defect of the grouting material of the reinforcement sleeve 1 based on the piezo-electrical impedance effect. Such as figure 1As shown, the basic principle is to pre-embed the piezoelectric ceramic sheet 2 in the middle of the surface of the non-defective, that is, grouted dense sleeve 1 and the defective, that is, grouted non-dense sleeve 1, and use the electromechanical coupling effect between the piezoelectric ceramic sheet 2 and the monitoring object. Measure the electrical admittance signal of the piezoelectric ceramic sheet 2. If there is a defect, that is, the grouting is not dense, compared with the sleeve 1 without defect, that is, the grouting is dense, the electrical admittance signal of the piezoelectric ceramic sheet 2 will change, and then qualitative and even quantitative Make judgments about defects. The monitoring method includes the following steps:

[0034] (1) Determination of the monitoring location: determi...

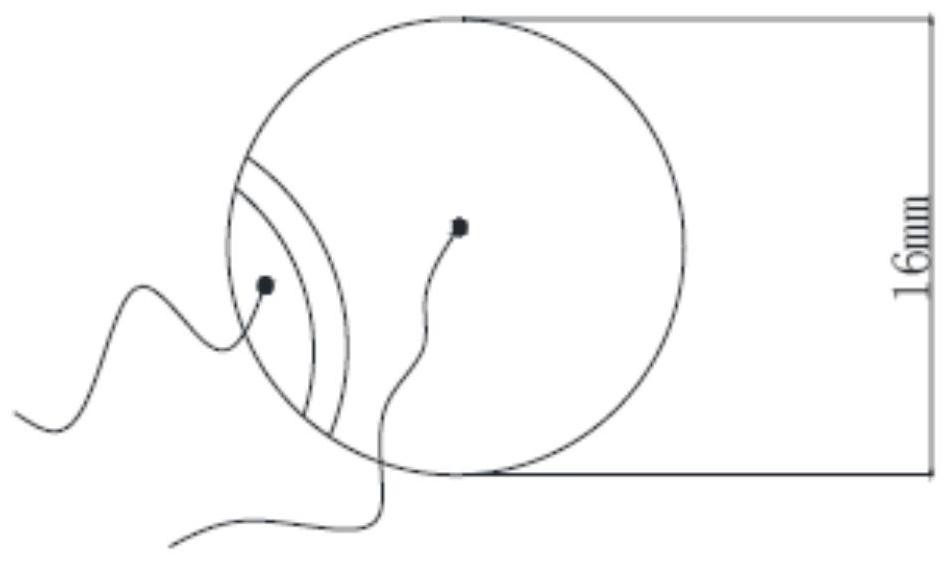

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com