Monitoring method of cast-in-situ prestressed concrete members and tensile stress of prestressed steels

A technology of prestressed steel bars and tensile stress is applied in the direction of measuring the force of frequency change by measuring the frequency change of the stressed vibration element, which can solve the problem of losing the monitoring function, and achieve the effects of convenient operation, light weight and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

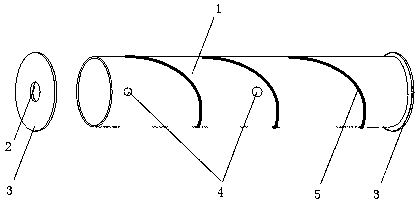

[0028] like figure 1 The schematic diagram of the three-dimensional structure of the protective device of the present invention is shown, and both ports of the columnar hollow pipe body 1 are provided with a plug 3; one end is a fixed port plug; the other end is a movable port plug, and the plug 3 is A through hole 2 is provided, and the outer diameter of the plug 3 is larger than the outer diameter of the pipe body 1 . The pipe body 1 is made of round steel pipe, with an outer diameter of 8-12 cm, a length of 0.6-1.0 m, and a thickness of 3-5 mm. The outer surface of the pipe body 1 is welded with a φ6 spiral steel bar 5 to strengthen the anchorage between the pipe body 1 and the concrete. Two through holes 4 are provided at the matching position of the pipe body 1 , one of which is provided in the middle as an oil injection hole, and the other is provided at the edge as a lead-out hole.

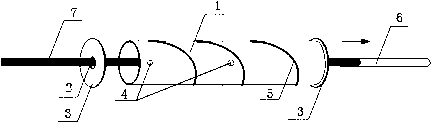

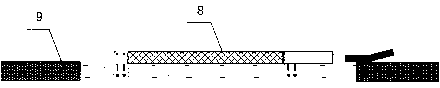

[0029] like figure 2 , image 3 , Figure 4 , Figure 5 The monitoring method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com