Backlight module

一种背光模组、光线的技术,应用在光导、光学、光学元件等方向,能够解决耗费电能等问题,达到节省电能、减少数量、光线均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

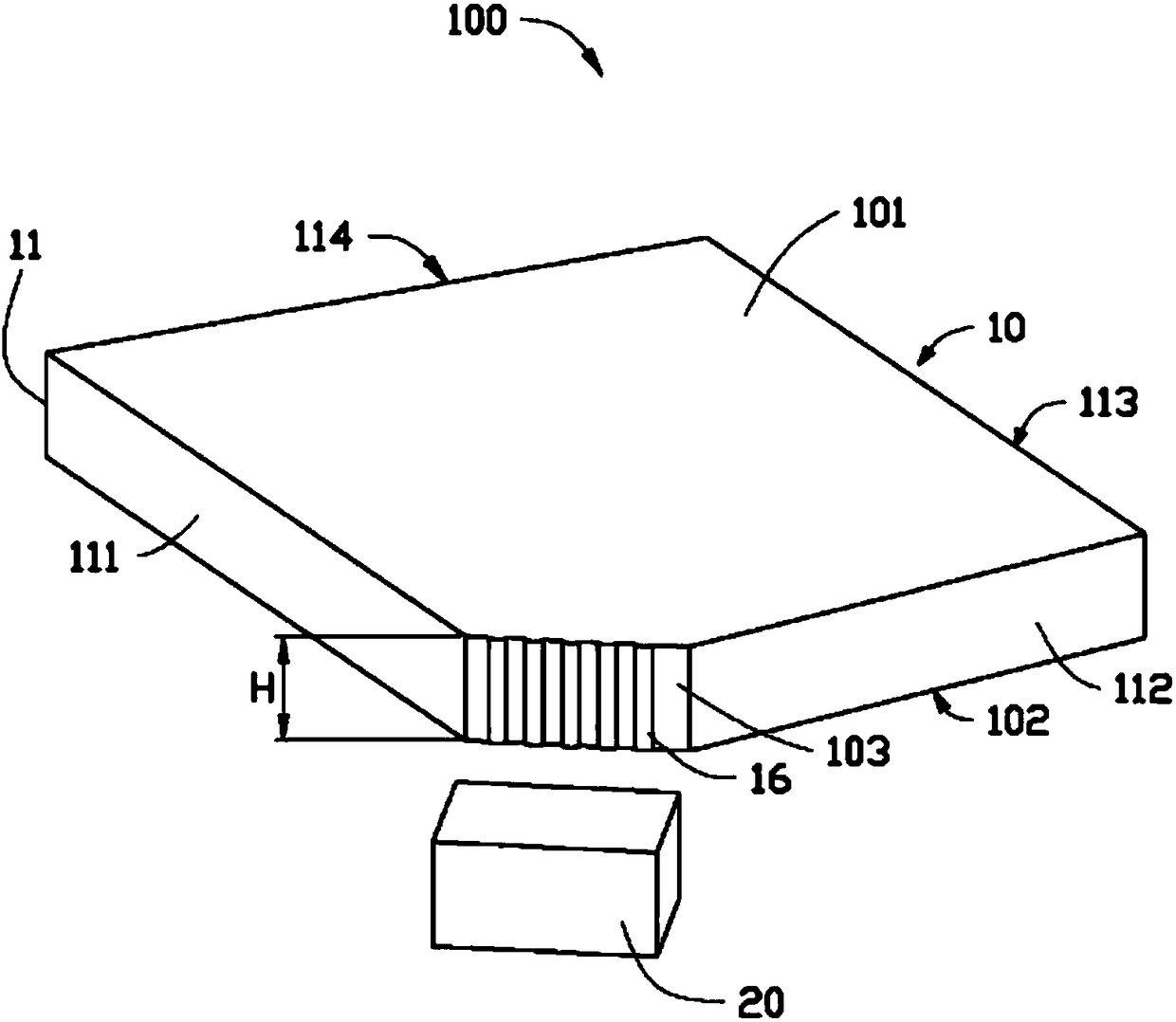

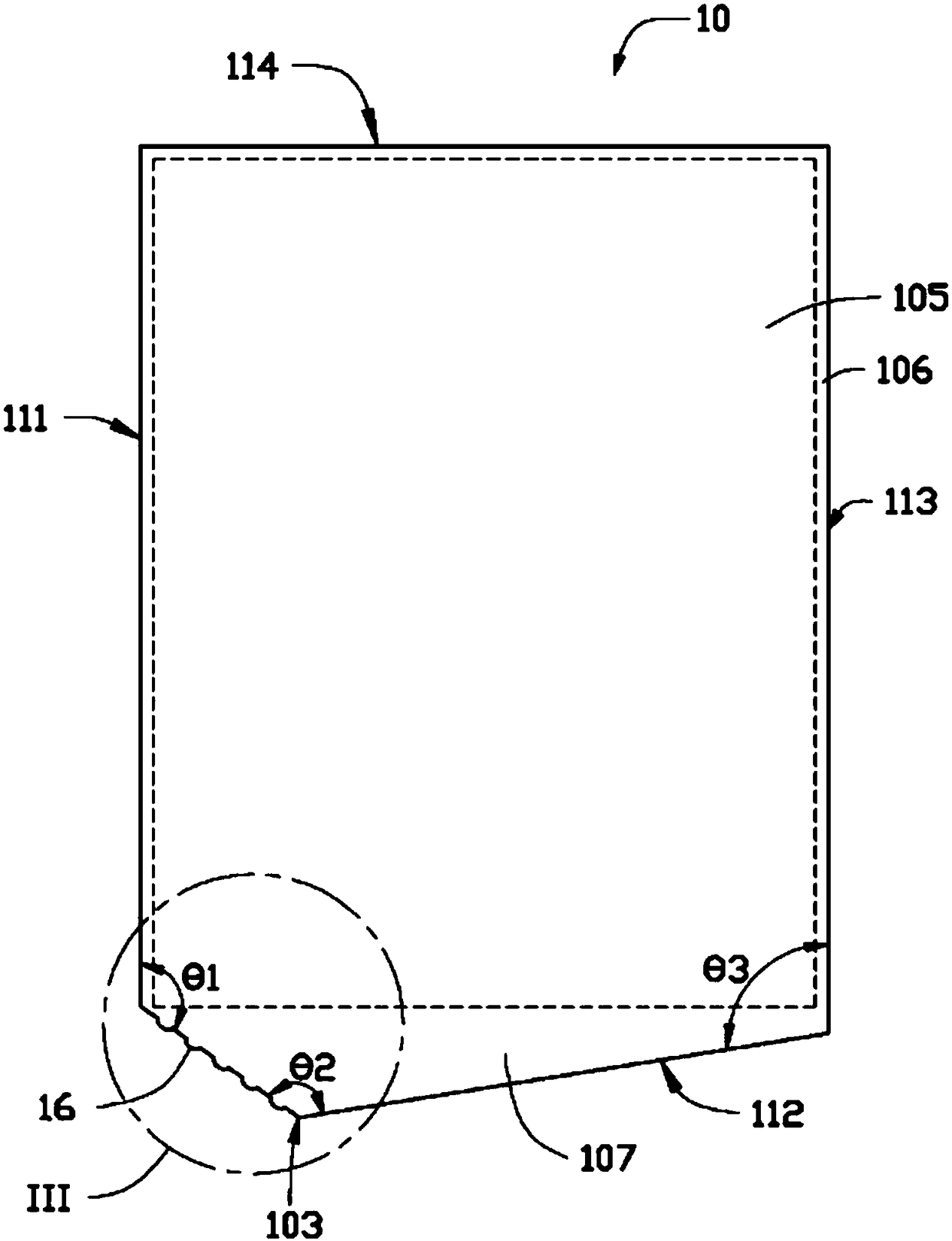

[0015] for see Figure 1-2 , is a backlight module 100 provided by an embodiment of the present invention, which includes a light guide plate 10 and only one light source 20 . In this embodiment, the light source 20 is a light emitting diode (Light emitting diode, LED).

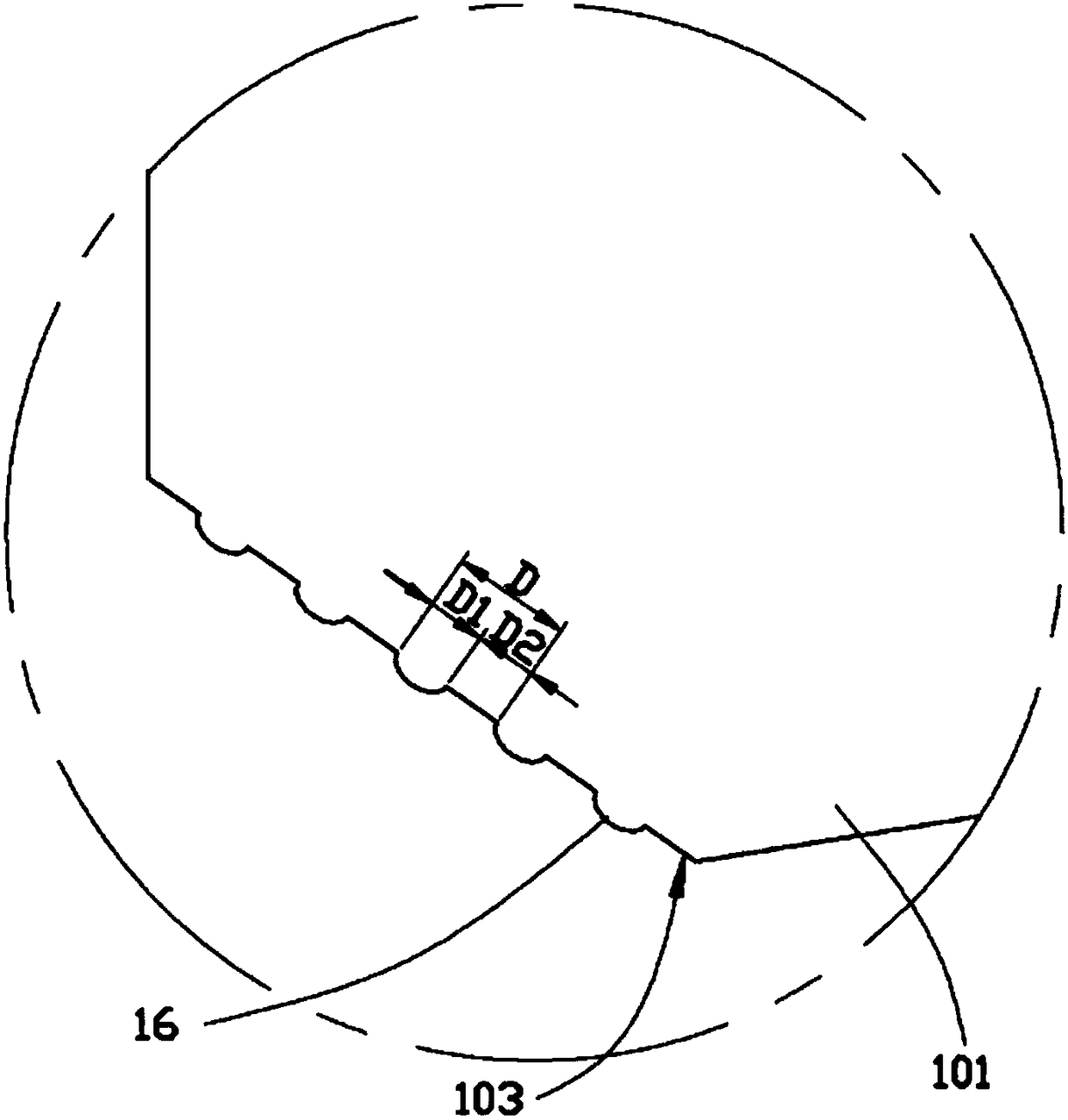

[0016] The light guide plate 10 is made of light-transmitting materials, such as acrylic resin, polycarbonate, polyethylene resin and the like. The light guide plate 10 includes a body 11 and a plurality of protrusions 16 . The main body 11 is in the shape of a pentagonal prism, and includes a light emitting surface 101 , a back surface 102 , a light incident surface 103 , a first side 111 , a second side 112 , a third side 113 and a fourth side 114 . The back surface 102 and the light emitting surface 101 are parallel to each other. The light incident surface 103 , the first side surface 111 , the second side surface 112 , the third side surface 113 and the fourth side surface 114 are vertically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com