A processing technology of ultra-thin ceramic fingerprint recognition sheet

A processing technology and fingerprint recognition technology, applied in the field of ultra-thin ceramic product processing, which can solve the problems of large demand for manpower and material resources and complex processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

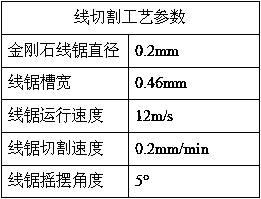

[0029] (1) Choose a ceramic fine rod with a diameter of 51.7 mm, and use a diamond wire saw to cut the incoming material to obtain a ceramic sheet with a thickness of 0.26 mm and a diameter of 51.7 mm. In this step, the specific wire cutting process parameters are:

[0030]

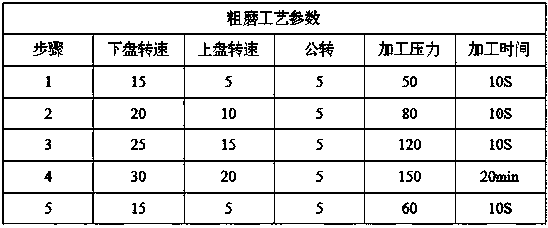

[0031] (2) Use a double-sided coarse grinder to rough grind the cut ceramic sheet with a boron carbide abrasive with a particle size of 30 μm to obtain a ceramic sheet with a thickness of 0.21±0.01 mm. In this step, the coarse grinding process includes 5 stages, and the specific coarse grinding process parameters are:

[0032]

[0033] (3) Chamfer the edges of the upper and lower surfaces of the roughly ground ceramic sheet with a grinding wheel rod or a grinding wheel of CNC or profiling equipment, and the size of the chamfering edge is 0.35mm.

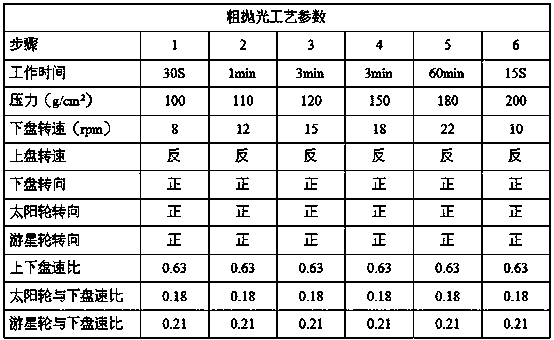

[0034] (4) Use a polishing machine to perform rough polishing on one side of the ceramic sheet that has been chamfered. After rough polishing, the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com