High-speed and precise glue spraying control system

A technology of control system and glue spraying, which is applied in general control system, control/adjustment system, program control, etc., can solve the problems of high price and complicated debugging process, and achieve the effect of simplifying installation and debugging, good use effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

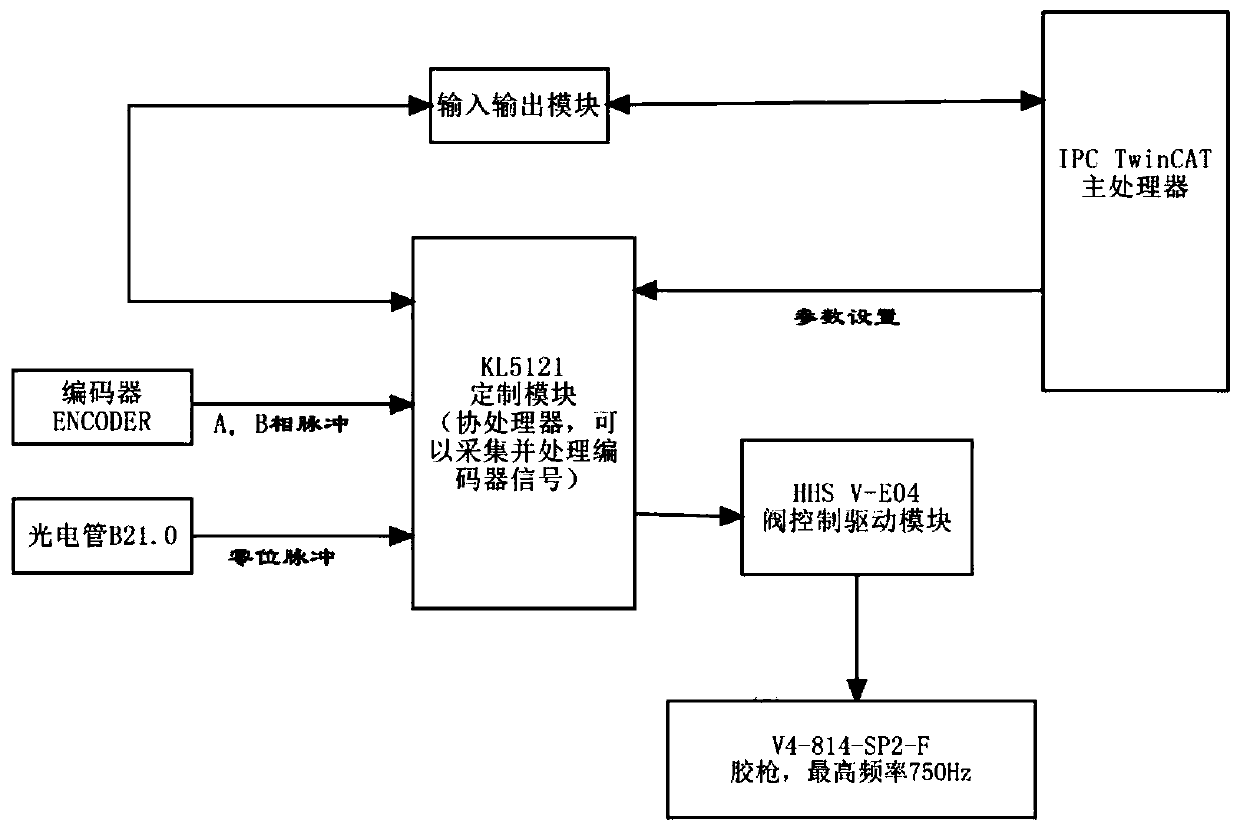

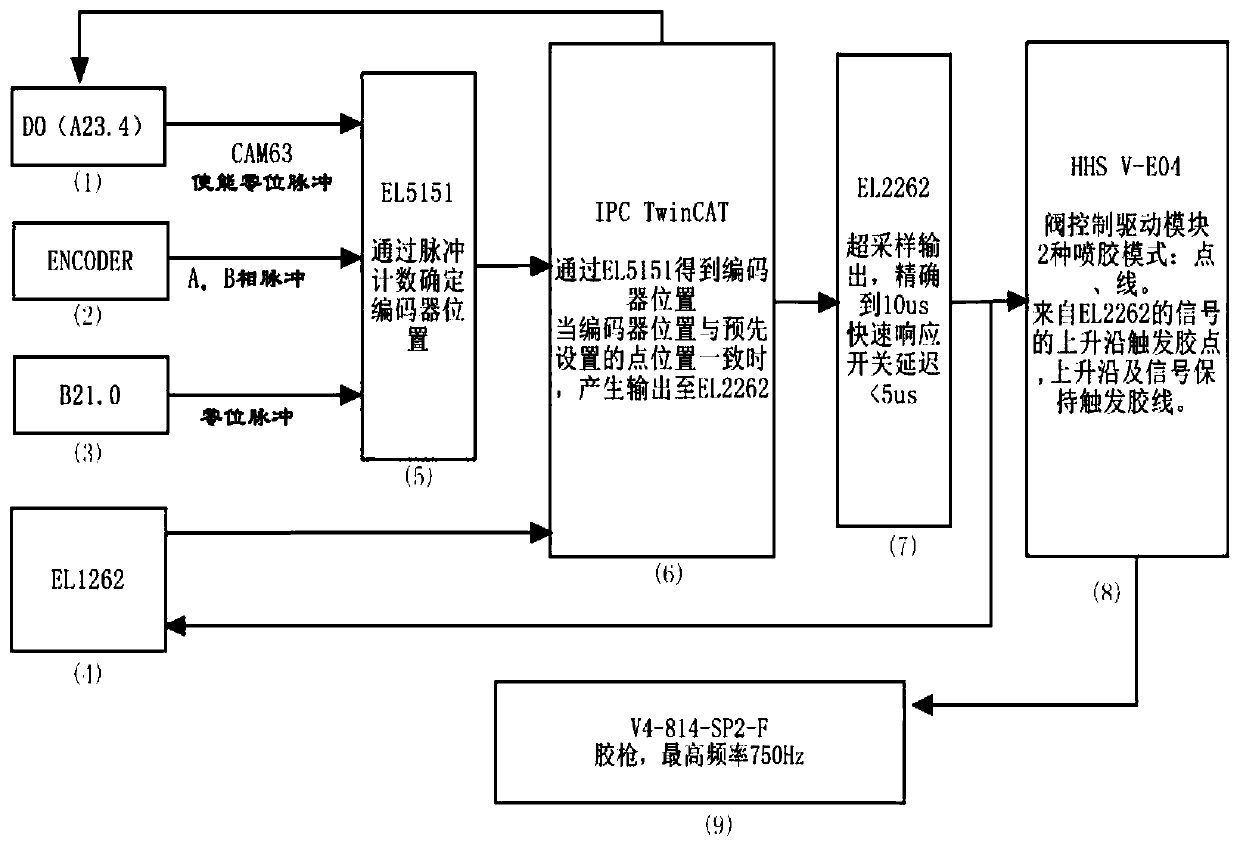

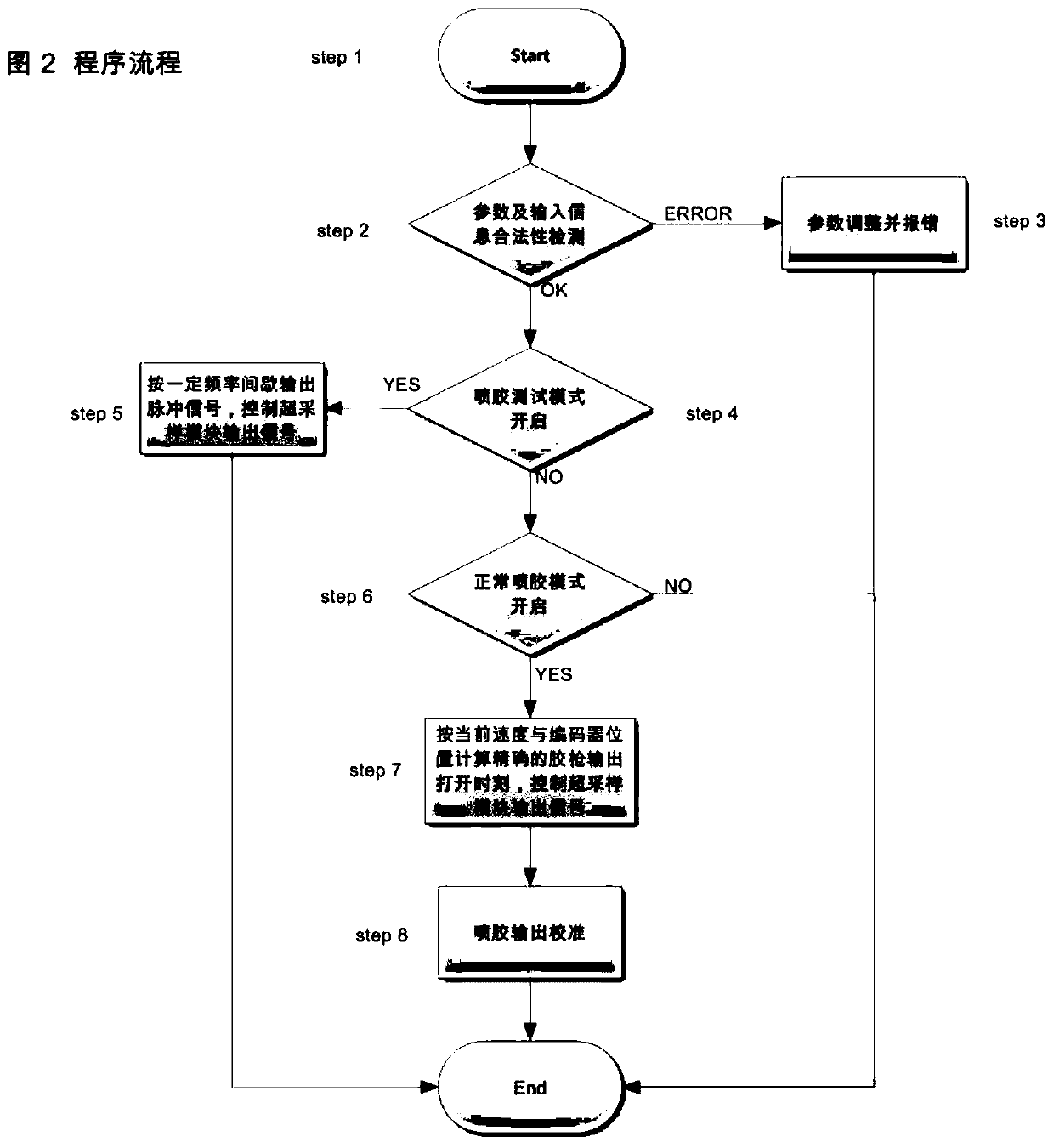

[0045] A high-speed and precise glue spraying control system in a preferred embodiment of the present invention includes a smoke machine industrial computer control module, an encoder, an encoder signal acquisition module, an input and output module, and a glue spray execution module, wherein the smoke machine industrial computer The control module is provided with a programmable controller; the input module outputs signals to the programmable controller; the encoder signal acquisition module receives the pulse signal of the encoder, determines the position of the encoder by pulse counting, and outputs the signal to the programmable controller Controller; the programmable controller obtains the position of the encoder through the encoder signal acquisition module, and outputs the signal to the output module when the position of the encoder is consistent with the preset point position; the output module outputs the signal to the glue spraying execution module , when the glue spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com