Combined flowerpot

A combined, flowerpot technology, applied in container cultivation, horticulture, botany equipment and methods, etc., can solve problems such as inability to illuminate flowers evenly, inability to perform soil loosening and ventilation, and inability to perform good display, etc. The effect of uniformity and avoidance of skewed growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

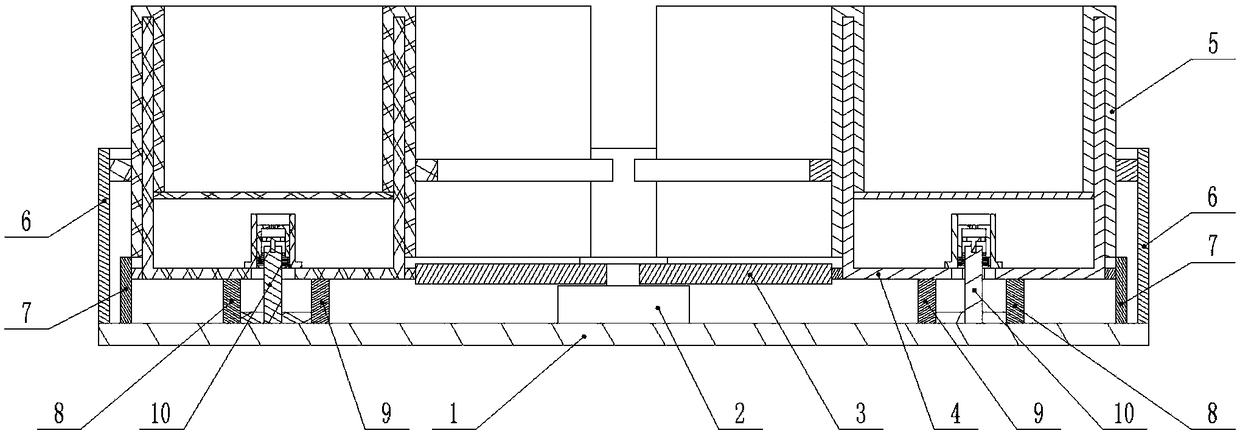

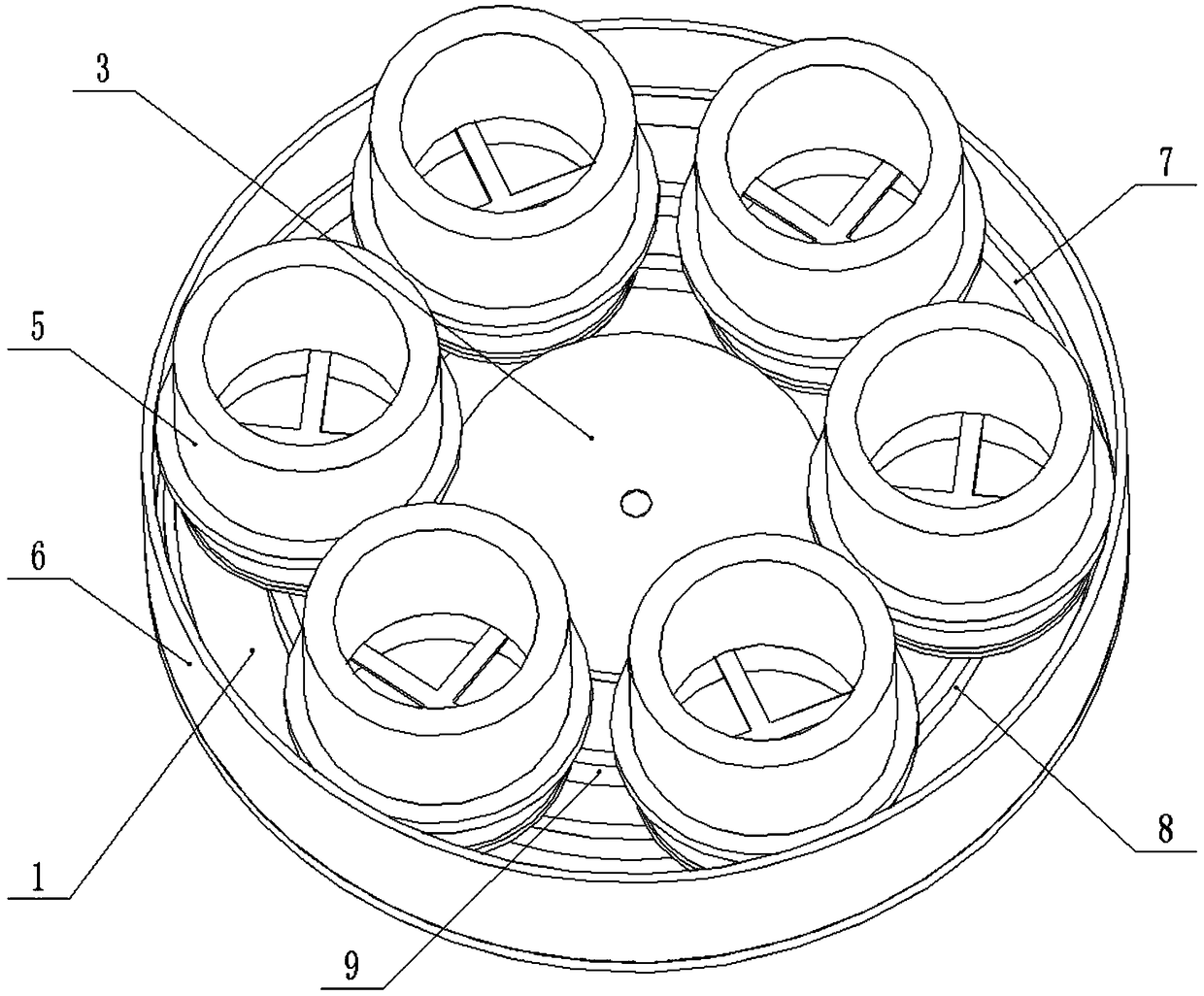

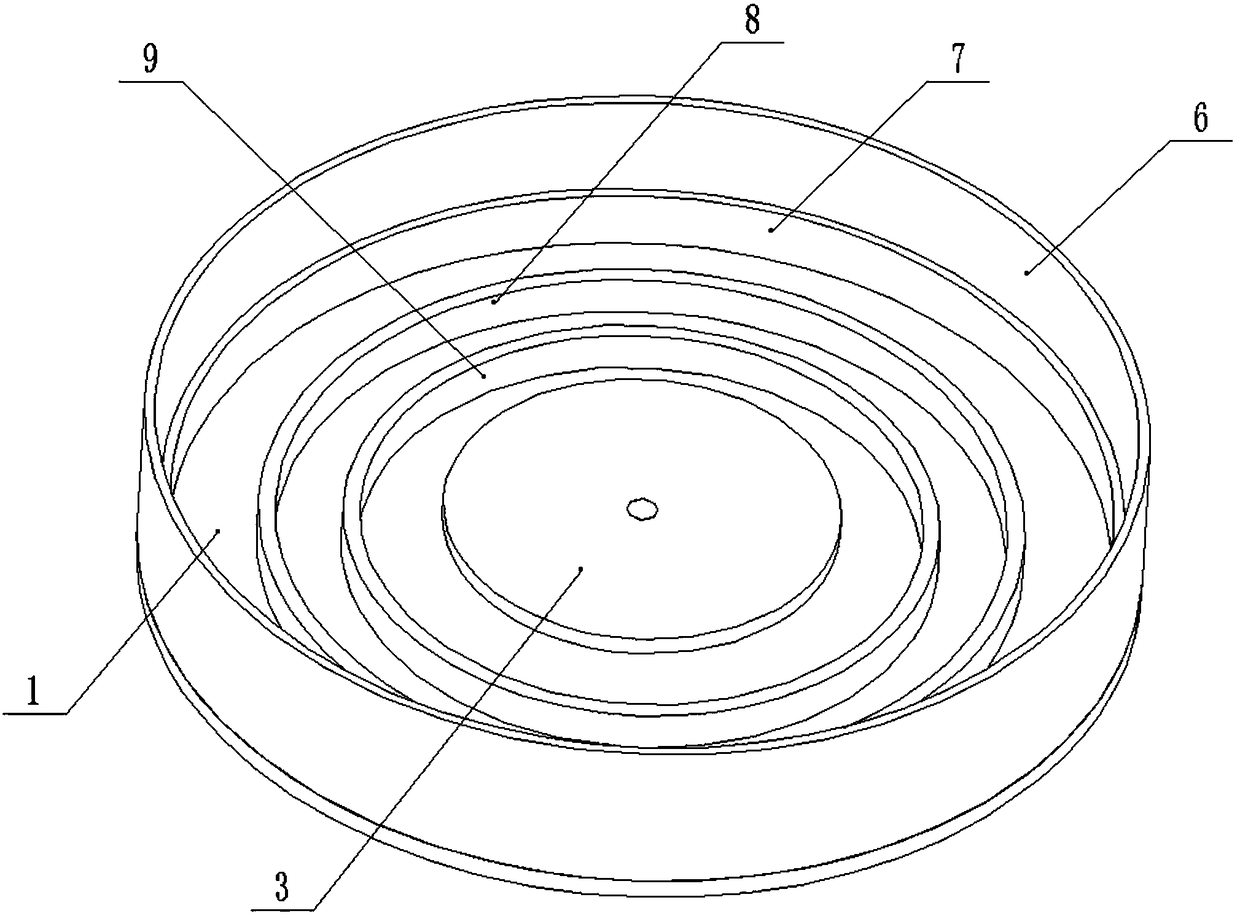

[0033] Combine below Figure 1-14Describe this embodiment, a combined flower pot, including a circular bottom plate 1, a drive motor 2, a drive gear 3, a flower pot lining body 4, a flower pot cover 5, an inner gear I6, an inner gear II7, an inner gear Ring III8, outer gear I9 and half-tooth ventilation assembly 10, the drive motor 2, inner gear I6, inner gear II7, inner gear III8 and outer gear I9 are all fixedly connected to the circular bottom plate 1, the The drive motor 2, the external gear I9, the internal gear III8, the internal gear II7 and the internal gear I6 are distributed sequentially from the inside to the outside and are coaxial, and the drive gear 3 is fixedly connected to the drive shaft of the drive motor 2, so The drive gear 3 is meshed with a plurality of flowerpot inner linings 4 through gear meshing, and the plurality of flowerpot inner linings 4 are evenly distributed in a circular shape. Mesh connection, the flower pot liner 4 is rotatably connected to...

specific Embodiment approach 2

[0034] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe Embodiment 1. The flowerpot lining body 4 includes a flowerpot barrel body 4-1 and an external gear II 4-2, and the external gear II 4-2 is fixedly connected to the The outer end of the flowerpot barrel body 4-1, the lower end surface of the flowerpot barrel body 4-1 is attached to the upper end surface of the inner ring gear III8 and the outer ring gear I9, and the driving gear 3 and the inner ring gear II7 are both It meshes with the outer ring gear Ⅱ4-2; the inner ring gear Ⅱ7 is fixed, and while the drive gear 3 drives the outer ring gear Ⅱ4-2 to rotate itself, the outer ring gear Ⅱ4-2 revolves along the inner ring gear Ⅱ7, which not only affects the inner lining of the flowerpot 4. The flowers in the interior are displayed in revolution, and the orientation of the flowers will be rotated and transformed to prevent the flowers from being fixed, which will cause the fl...

specific Embodiment approach 3

[0035] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain Embodiment 2, the bottom end of the inside of the flowerpot barrel 4-1 is fixedly connected with a plunger sleeve 4-3, and the bottom of the flowerpot barrel 4-1 The lower end is provided with a threaded through hole 4-4, and the lower end of the flower pot barrel 4-1 is provided with a plurality of fan-shaped vents 4-5, and the plurality of fan-shaped vents 4-5 communicate with the threaded through hole 4-4; The toothed ventilation assembly 10 is connected in the threaded through hole 4-4 through thread fit, and during the reciprocating movement of the half-toothed ventilation assembly 10 up and down, a plurality of fan-shaped ventilation openings 4-5 play a ventilation role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com