A uranium enrichment plant exhaust gas hf treatment process

A technology for treating process and tail gas, applied in the field of uranium enrichment process, can solve the problems of complex process, unfavorable safety and environmental protection, and high comprehensive cost, and achieve the effects of simplifying process, being beneficial to environmental protection, and improving safety and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

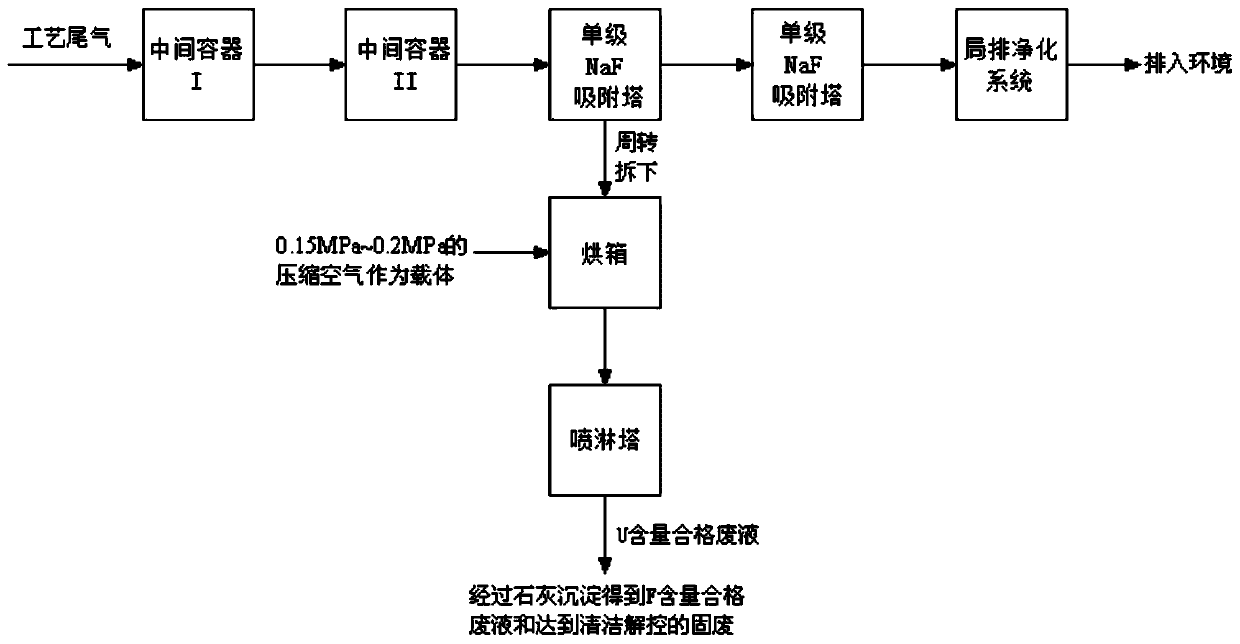

[0052] Such as figure 1 As shown, adopting the process of this embodiment to carry out HF treatment of feed material purification and concentrate purification system tail gas includes the following steps:

[0053] Step S1

[0054] The exhaust gas first enters the intermediate container I frozen in the refrigerator at about -80°C, and UF at -80°C 6 The saturated vapor pressure is 0.19Pa, so most of UF 6 Desublimation in the intermediate container I, UF in the tail gas 6 The mass ratio to HF is reduced to around 10%.

[0055] In this embodiment, the pressure at the inlet of the intermediate container I is less than or equal to 800 Pa, and the opening of the valve at the outlet of the intermediate container I is 1 to 2 turns.

[0056] Step S2

[0057] The tail gas treated in step S1 enters the intermediate container II frozen in a refrigerator at about -90°C, and UF at -90°C 6 The saturated vapor pressure is 0.032Pa, and at this time UF 6 content has been substantially r...

Embodiment 2

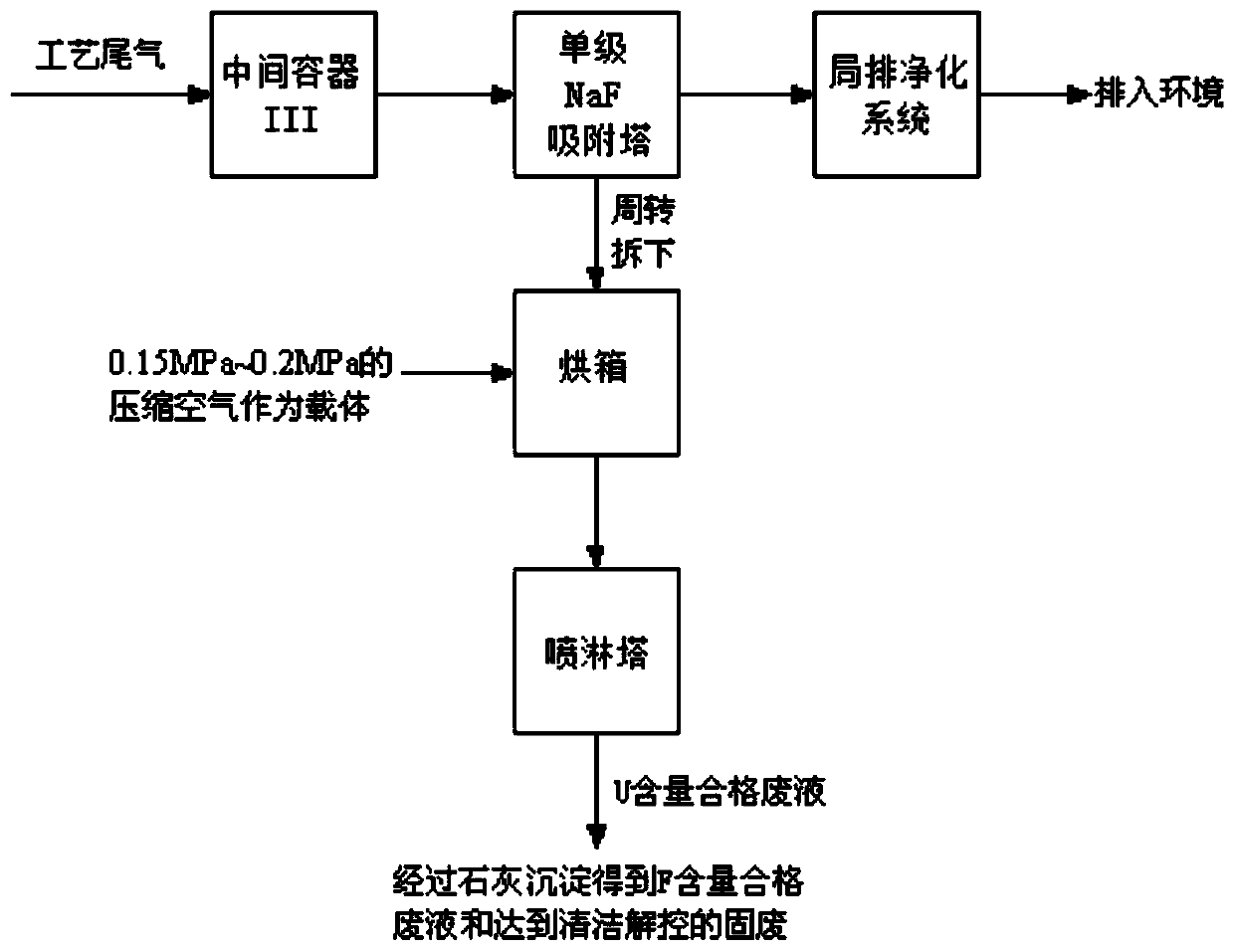

[0076] Such as figure 2 As shown, adopting the process of this embodiment to carry out purging and evacuating system tail gas HF treatment includes the following steps:

[0077] Step P1

[0078] The exhaust gas first enters the intermediate container III frozen in the refrigerator at about -80°C, and UF at -80°C 6 The saturated vapor pressure is 0.19Pa, after UF 6 Desublimation, UF in exhaust 6 The mass ratio to HF is reduced from about 10% to 0.00001 or even lower. This step can ensure that the U content in the tail gas is qualified.

[0079] In this embodiment, the pressure at the inlet of the intermediate container III is less than or equal to 800 Pa, and the opening of the valve at the outlet of the intermediate container III is 1 to 2 turns.

[0080] Step P2

[0081] The tail gas treated in step P1 enters the single-stage NaF adsorption tower, and HF reacts with NaF to produce NaHF 2 , thus being collected by adsorption.

[0082] In this example, in order to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com