Putty powder stirring equipment for decoration

A technology of mixing equipment and putty powder, which is applied in the directions of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of affecting the beauty of the wall, unable to quantitatively add water, uneven mixing, etc., and achieves convenient use, low manufacturing cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

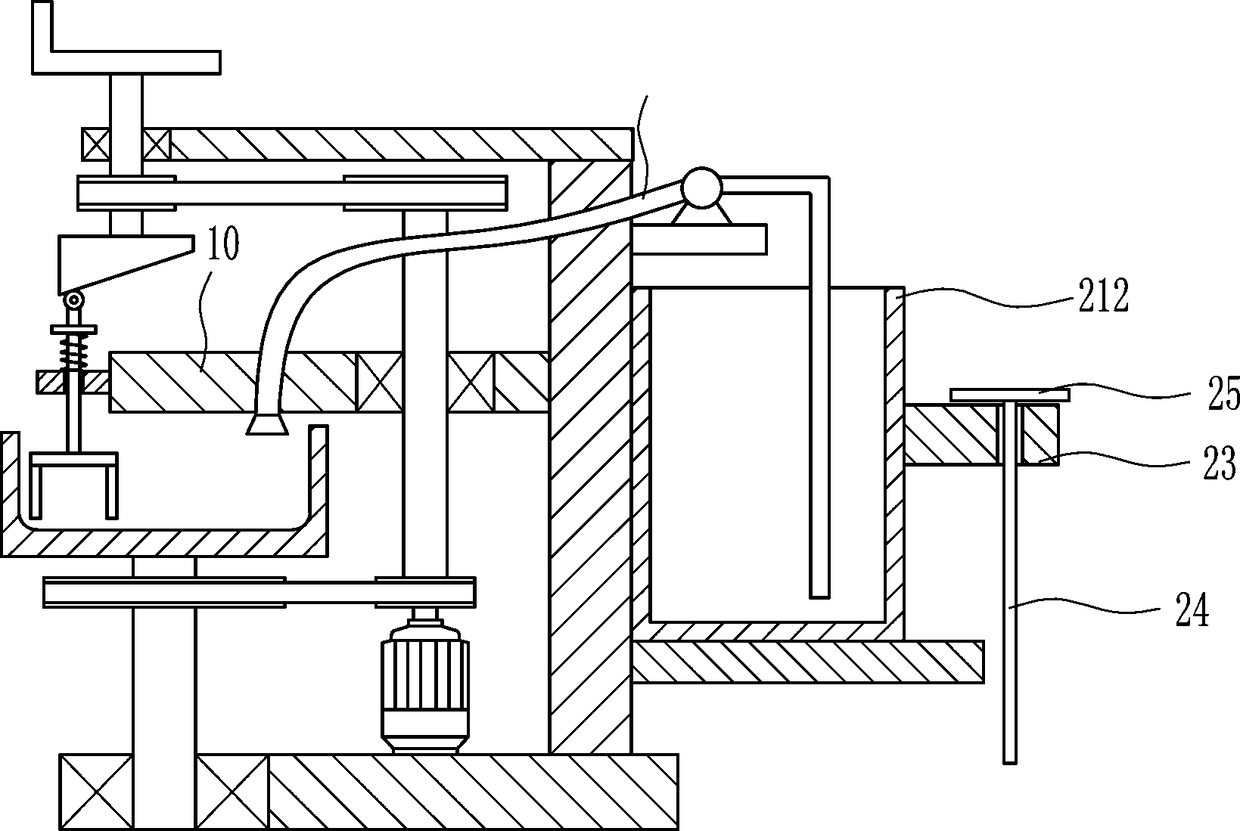

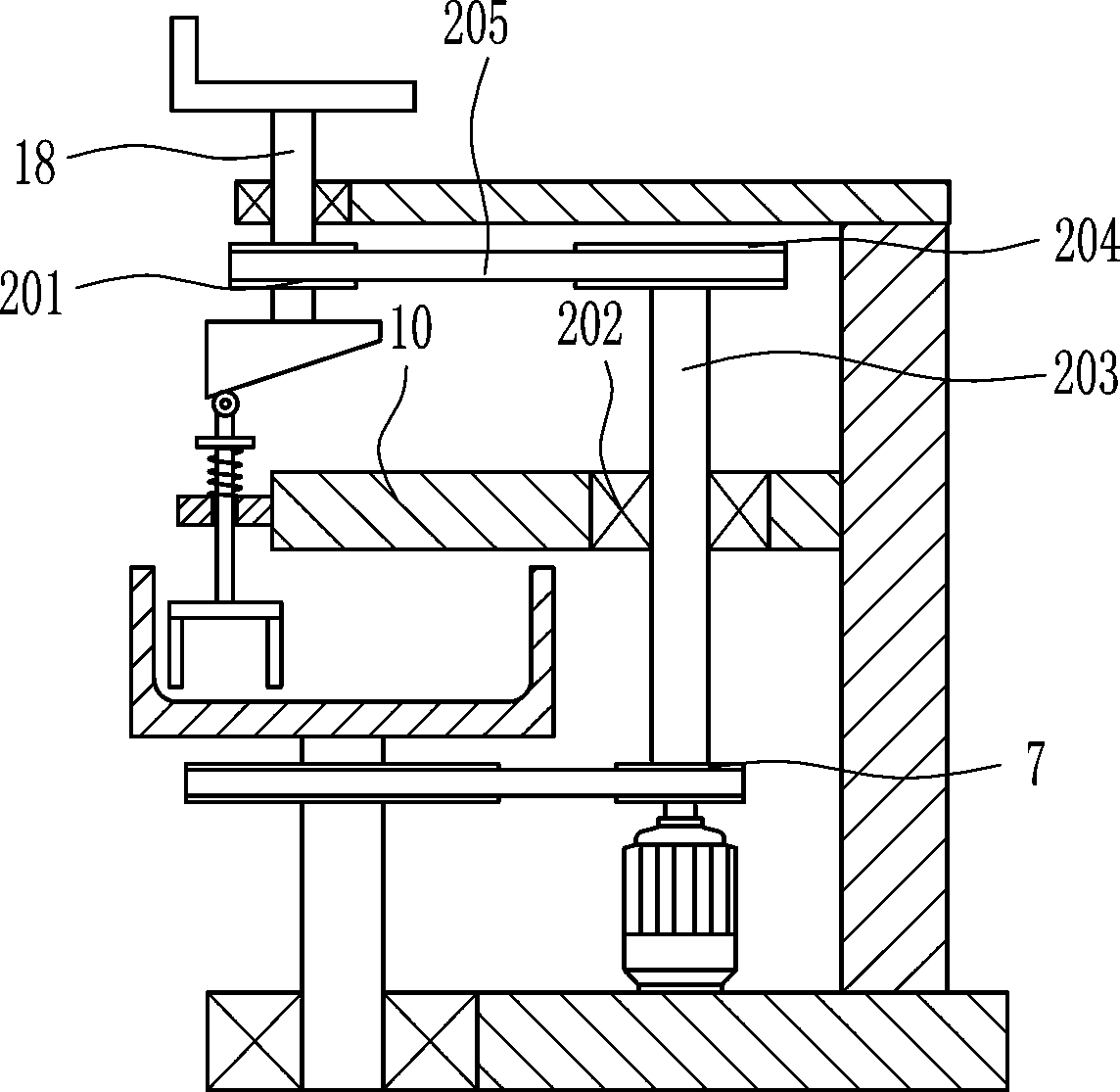

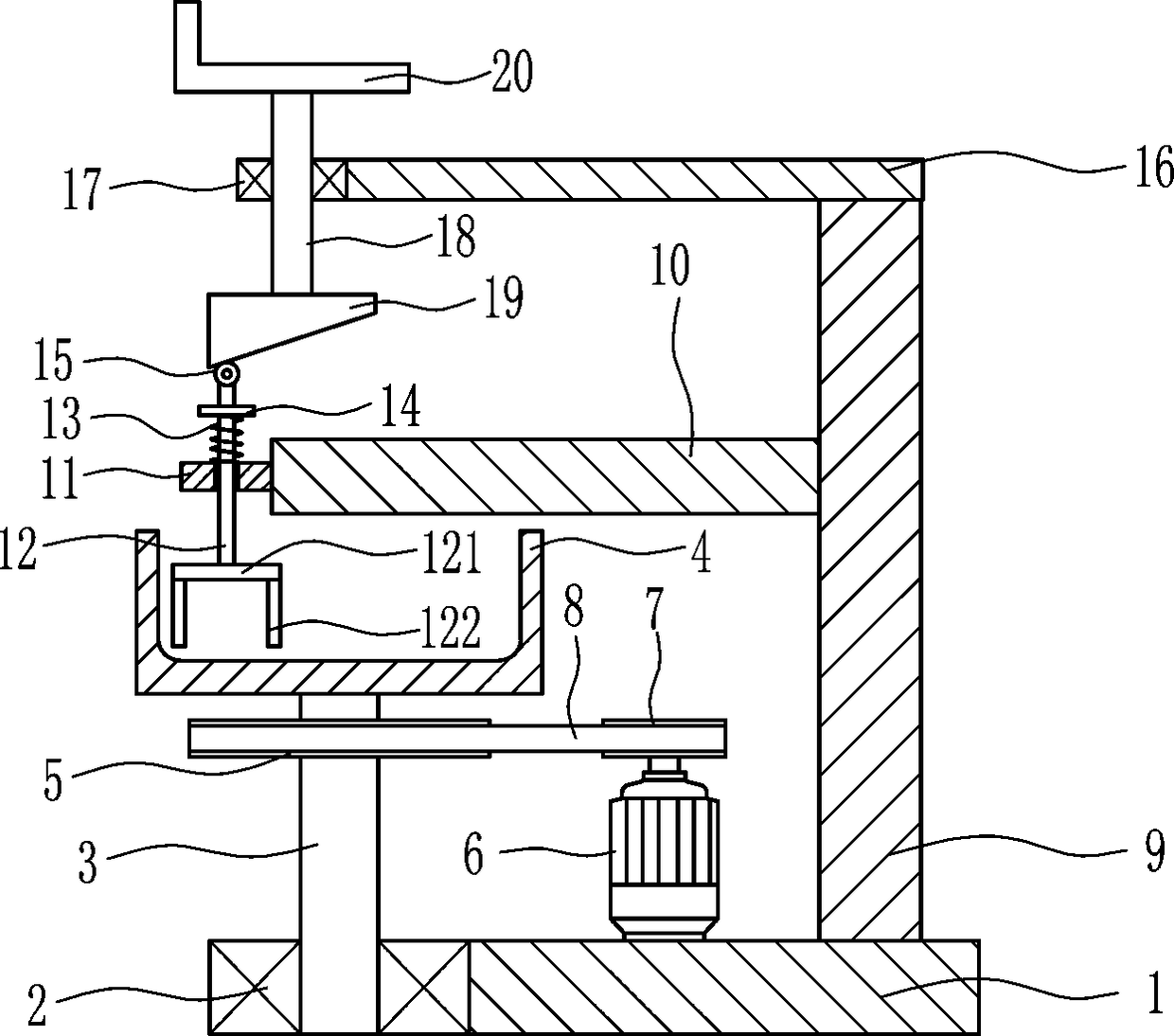

[0026] A kind of putty powder mixing equipment for decoration, such as Figure 1-5 As shown, it includes a base 1, a first bearing 2, a first rotating shaft 3, a stirring box 4, a first pulley 5, a first motor 6, a second pulley 7, a first belt 8, a first bracket 9, a first Two support 10, the 3rd support 11, slide bar 12, rotating disk 121, stirring bar 122, spring 13, baffle plate 14, roller 15, the 4th support 16, the second bearing 17, the second rotating shaft 18, cam 19 and rock The handle 20 is fixedly connected with the first bearing 2 at the left end of the base 1, the first rotating shaft 3 is connected with the interference in the first bearing 2, and the stirring box 4 is fixedly connected at the top of the first rotating shaft 3, and the first rotating shaft 3 The upper is fixedly connected with the first pulley 5, on the base 1 is fixedly connected with the first motor 6, on the output shaft of the first motor 6, the second pulley 7 is connected with interference...

Embodiment 2

[0028] A kind of putty powder mixing equipment for decoration, such as Figure 1-5As shown, it includes a base 1, a first bearing 2, a first rotating shaft 3, a stirring box 4, a first pulley 5, a first motor 6, a second pulley 7, a first belt 8, a first bracket 9, a first Two support 10, the 3rd support 11, slide bar 12, rotating disk 121, stirring bar 122, spring 13, baffle plate 14, roller 15, the 4th support 16, the second bearing 17, the second rotating shaft 18, cam 19 and rock The handle 20 is fixedly connected with the first bearing 2 at the left end of the base 1, the first rotating shaft 3 is connected with the interference in the first bearing 2, and the stirring box 4 is fixedly connected at the top of the first rotating shaft 3, and the first rotating shaft 3 The upper is fixedly connected with the first pulley 5, on the base 1 is fixedly connected with the first motor 6, on the output shaft of the first motor 6, the second pulley 7 is connected with interference,...

Embodiment 3

[0031] A kind of putty powder mixing equipment for decoration, such as Figure 1-5 As shown, it includes a base 1, a first bearing 2, a first rotating shaft 3, a stirring box 4, a first pulley 5, a first motor 6, a second pulley 7, a first belt 8, a first bracket 9, a first Two support 10, the 3rd support 11, slide bar 12, rotating disk 121, stirring bar 122, spring 13, baffle plate 14, roller 15, the 4th support 16, the second bearing 17, the second rotating shaft 18, cam 19 and rock The handle 20 is fixedly connected with the first bearing 2 at the left end of the base 1, the first rotating shaft 3 is connected with the interference in the first bearing 2, and the stirring box 4 is fixedly connected at the top of the first rotating shaft 3, and the first rotating shaft 3 The upper is fixedly connected with the first pulley 5, on the base 1 is fixedly connected with the first motor 6, on the output shaft of the first motor 6, the second pulley 7 is connected with interference...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap