Oiling machine of waterproof equipment

An oiling machine and equipment technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of not being able to control the amount of oil applied, and achieve the effect of long service life and fast adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

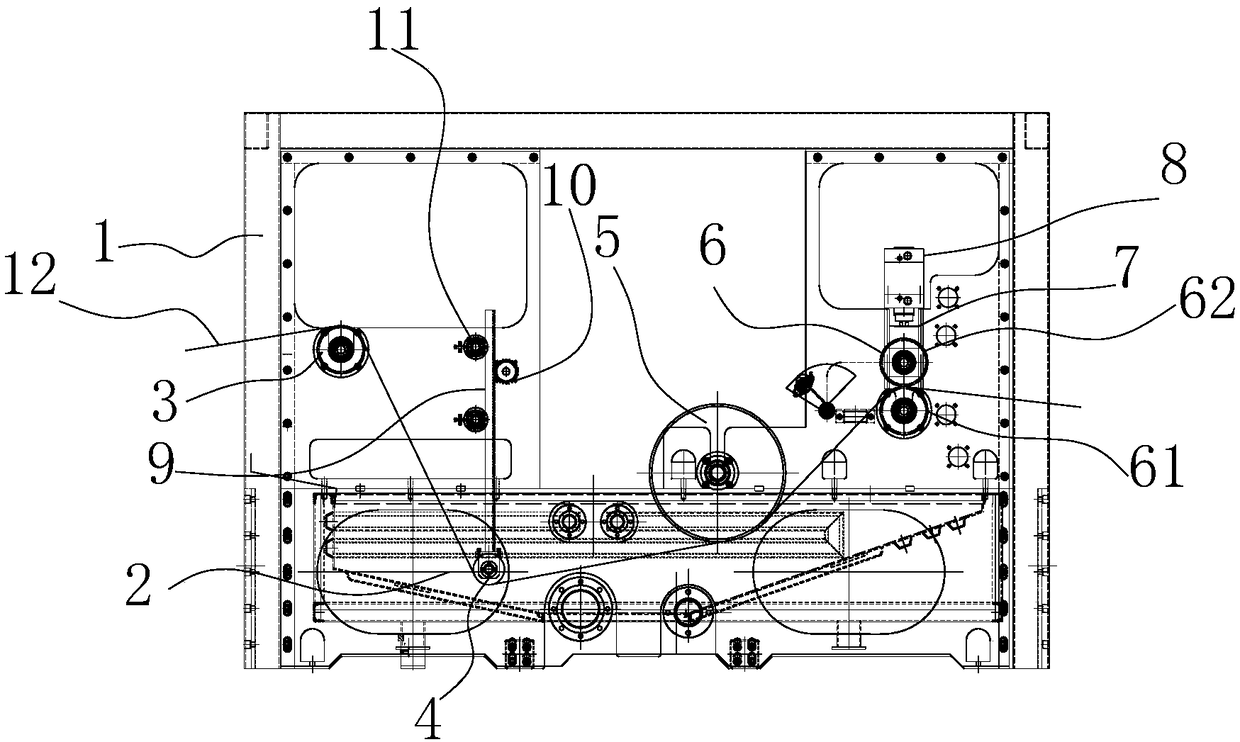

[0013] Such as figure 1 , an oiler for waterproof equipment, comprising a frame 1, an oiling pool 2 is provided at the bottom of the frame 1, and guide heating rollers 3 are arranged on the frame 1 from left to right in order to adjust the tire cloth to enter the oiling pool 2 Length adjustment roller 4 up and down, tire cloth driving roller 5 and oiling thickness measuring mechanism 6, oiling thickness measuring mechanism 6 includes fixed roller 61 and floating roller 62 that are squeezed each other, the tire cloth that has been oiled is passed from fixed roller 61 Passes between the floating roller 62, the frame 1 is provided with a position sensor for detecting the position of the floating roller 62, the top of the upper and lower adjustment rollers 4 is connected with a first drive mechanism that drives the movement of the upper and lower adjustment rollers 4, and the floating roller 62 is connected with Second drive mechanism.

[0014] The floating roller 62 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com