LF furnace bottom argon blowing bi-branch flow control device

A flow control device and flow controller technology, applied in the direction of flow control, flow control using electric devices, non-electric variable control, etc., can solve the problems of complex structure of mechanical parts, short adjustment process, system vibration, etc., and achieve good control accuracy. and stability, the adjustment process is short, and the step response is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

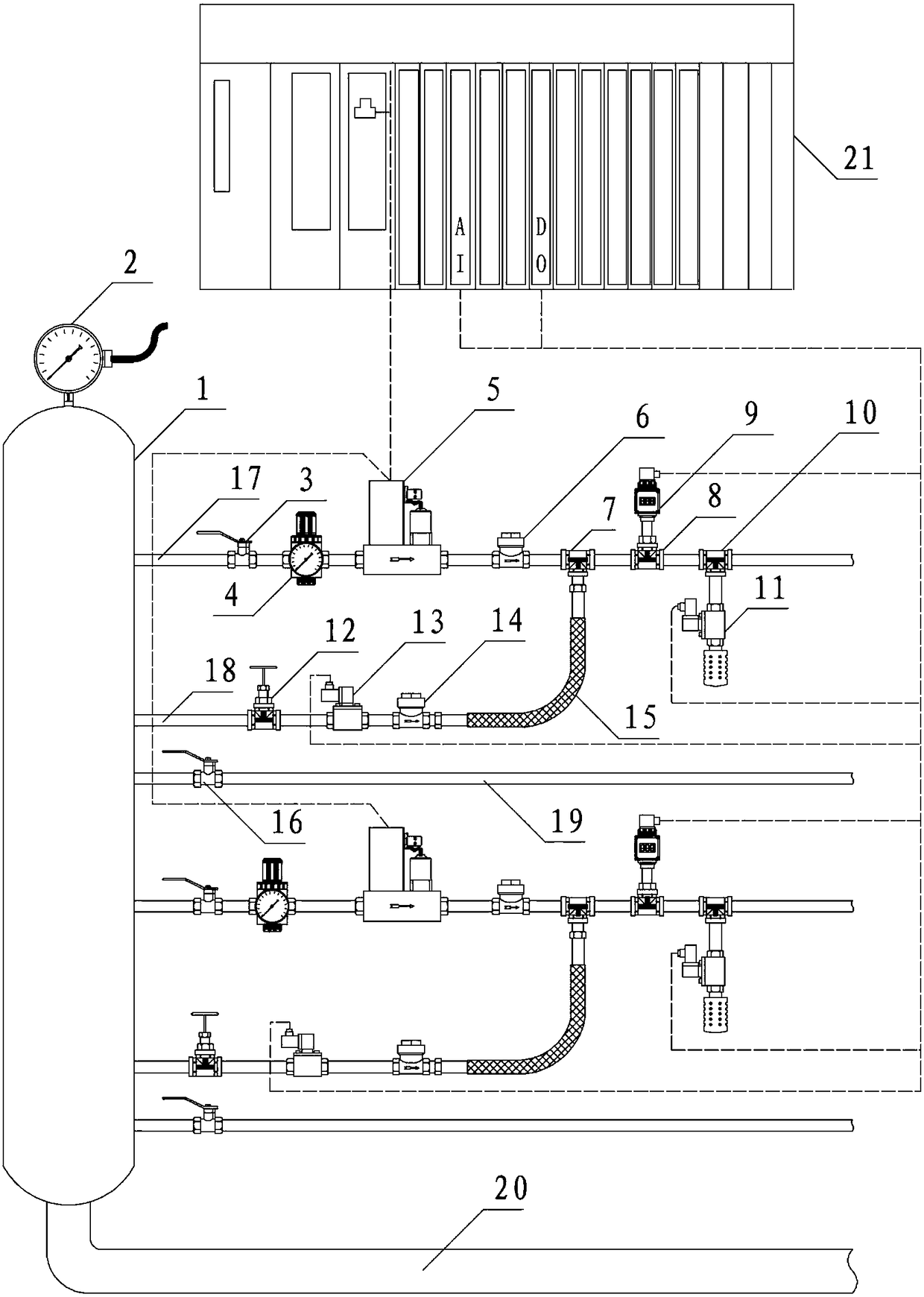

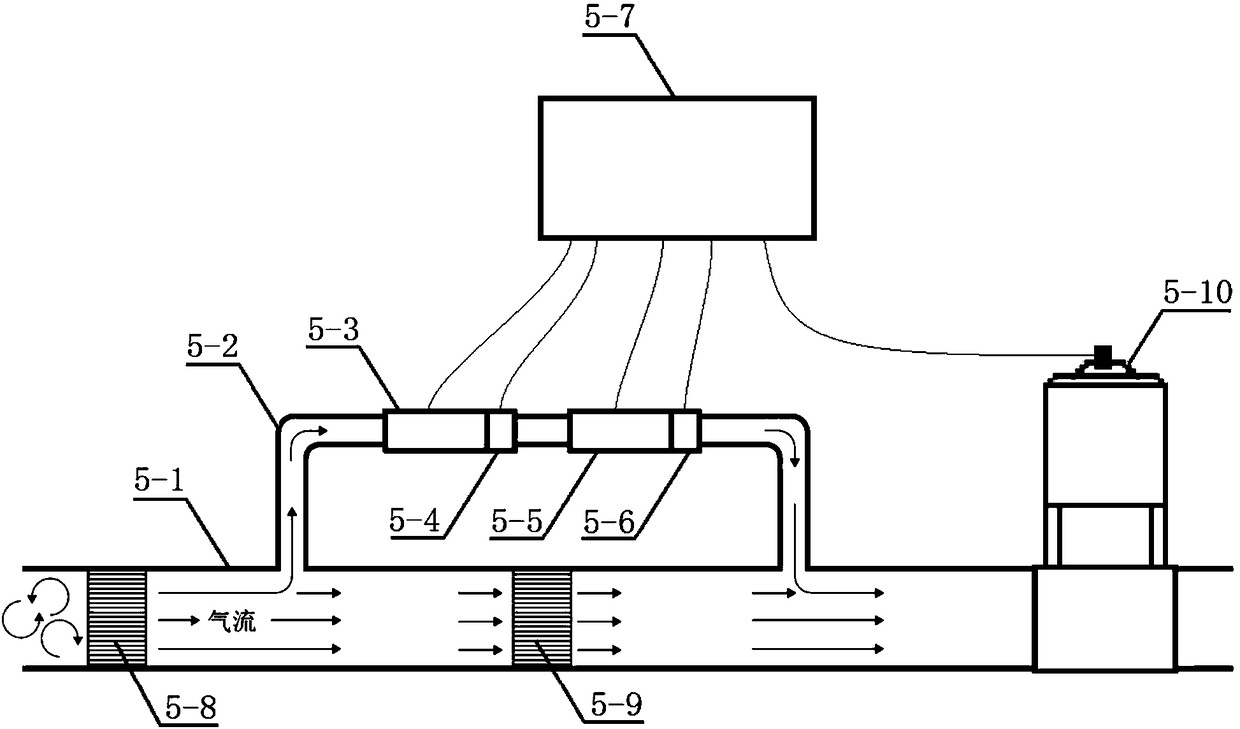

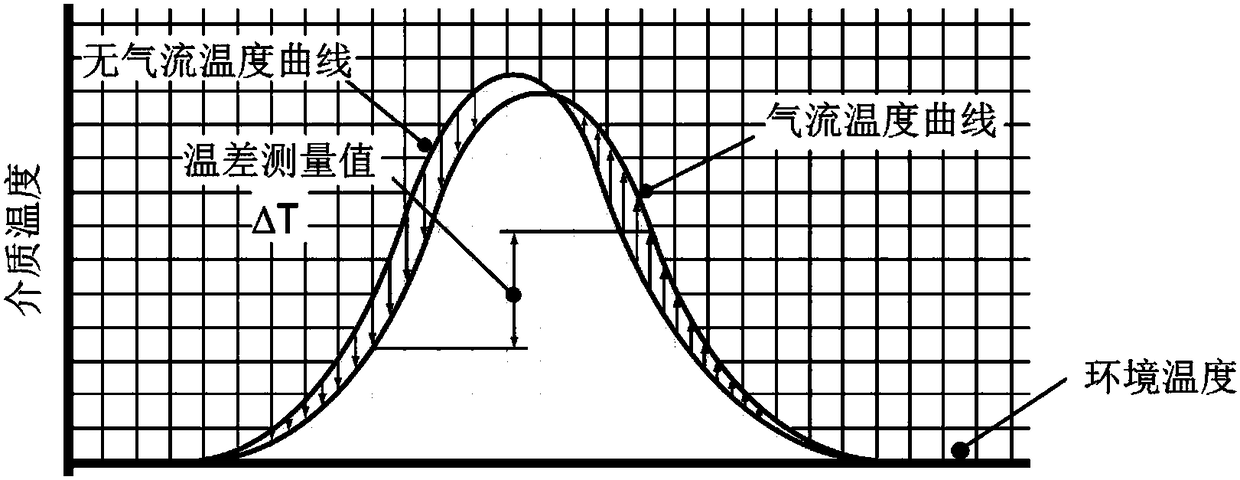

[0022] see figure 1 and figure 2 , the present invention mainly consists of a stabilized pressure distributor 1, a gas source pressure remote transmission meter 2, an argon blowing balloon valve 3, an overflow type pressure regulating unit 4, an integrated thermal mass flow controller 5, and a main blowing check valve 6 , 90-degree side blowing tee 7, 90-degree source tee 8, shock-resistant pressure display transmitter 9, 90-degree pressure relief tee 10, noise reduction and pressure relief unit 11, side blowing intake stop valve 12, side blowing Control unit 13, bypass check valve 14, rubber hose assembly 15, redundant inlet ball valve 16, PLC controller 21 and other stainless steel pipe fittings. The device is protected by a cabinet, and the size of the cabinet is H1600 x W1800 x D400. The connection method of the pipe fittings in the device is screw connection, and the connection thread is wrapped with Teflon tape. The right side of the inside of the box is the inlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com