A method for consistency screening of lithium iron phosphate batteries

A lithium iron phosphate battery, consistent technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of consistency and inability to guarantee the dynamic characteristics of the battery, so as to reduce the abnormal voltage difference, realize effective grouping, and ensure accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

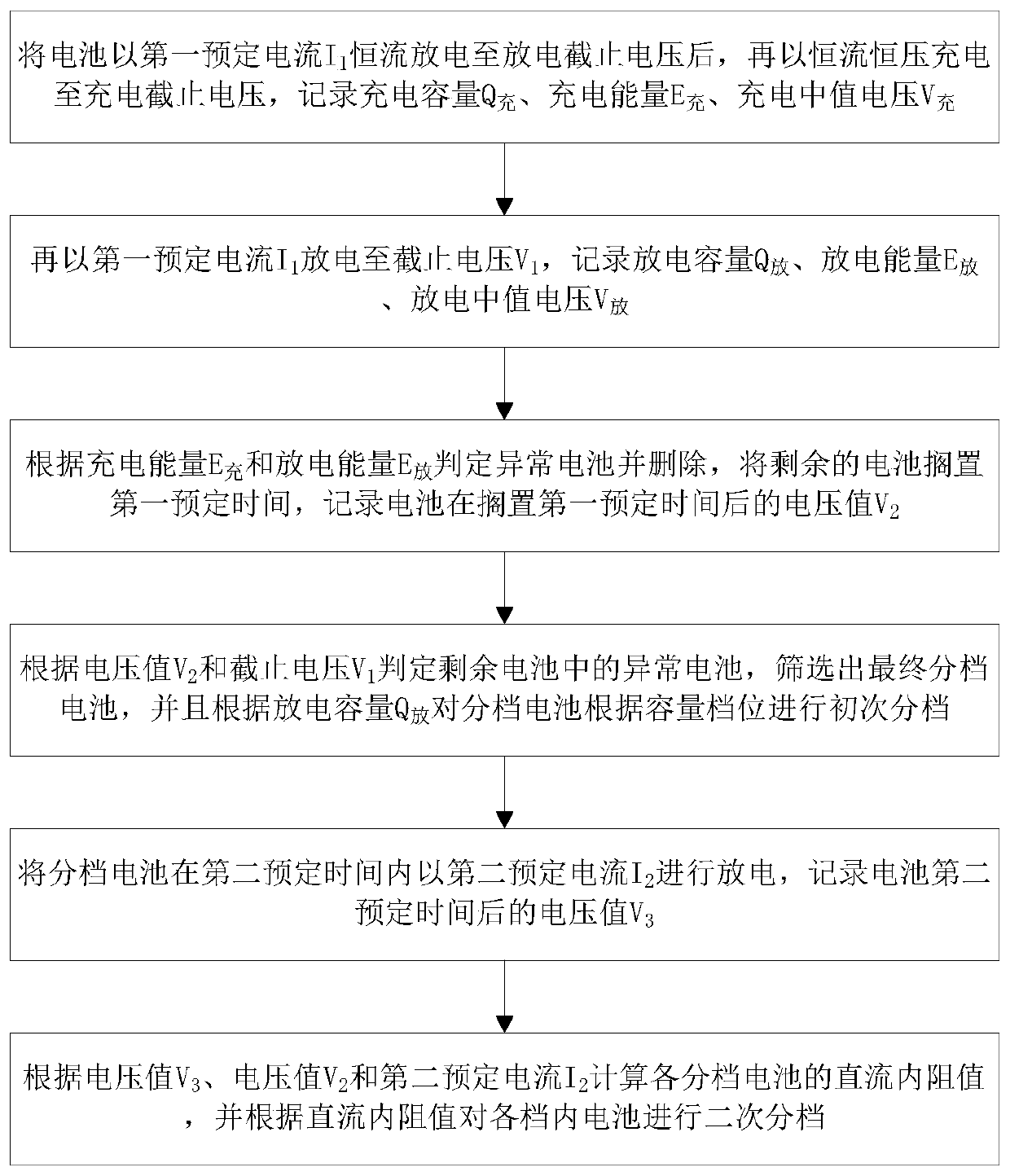

[0020] refer to figure 1 In the following, a plurality of lithium iron phosphate batteries are selected to describe a method for consistency screening of lithium iron phosphate batteries proposed by the present invention, which specifically includes the following steps.

[0021] S1. Charge the battery with the first predetermined current I 1 After constant current discharge to the discharge cut-off voltage, then charge to the charge cut-off voltage with constant current and constant voltage, and record the charging capacity Q 充 , charging energy E 充 , charging median voltage V 充 . Specifically in this step, the charging cut-off voltage is 3.65V.

[0022] S2, and then with the first predetermined current I 1 Discharge each cell to the cutoff voltage V 1 , record the discharge capacity Q 放 , discharge energy E 放 , discharge median voltage V 放 . V 1 = 2.5V.

[0023] In this way, through the above two steps, the battery is charged with the first predetermined current I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com