Lithium battery assembly method and device

A lithium battery pack, lithium battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of low consistency requirements of lithium batteries, affecting battery system life, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

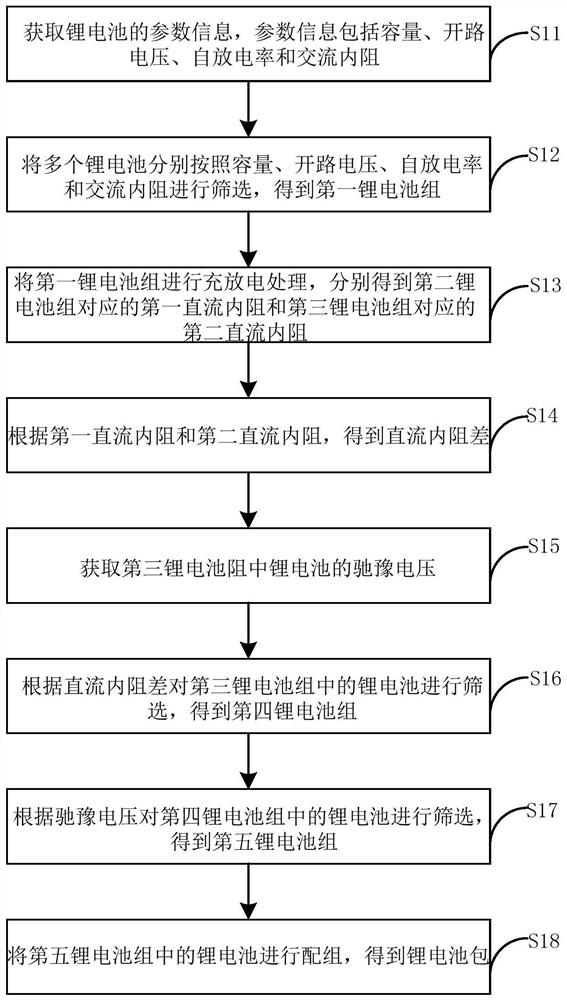

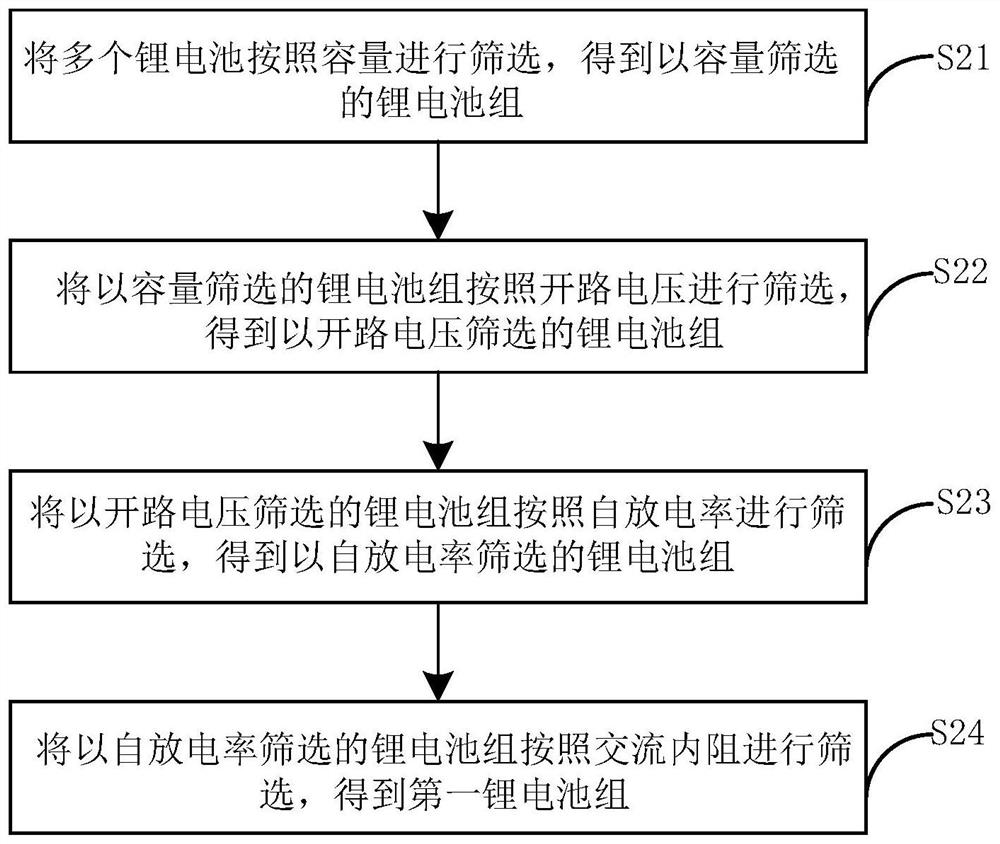

[0070] figure 1 It is a flow chart of the lithium battery assembly method provided by Embodiment 1 of the present invention.

[0071] refer to figure 1 , the method includes the following steps:

[0072] Step S11, obtaining the parameter information of the lithium battery, the parameter information includes capacity, open circuit voltage, self-discharge rate and AC internal resistance;

[0073] Step S12, screening a plurality of lithium batteries according to capacity, open circuit voltage, self-discharge rate and AC internal resistance to obtain a first lithium battery pack;

[0074] Here, the lithium batteries are grouped by static grouping. That is to obtain the parameter information of the lithium battery, screen the multiple lithium batteries according to the capacity, open circuit voltage, self-discharge rate and AC internal resistance in the parameter information, and form the first lithium battery pack with the lithium batteries obtained after screening.

[0075] S...

Embodiment 2

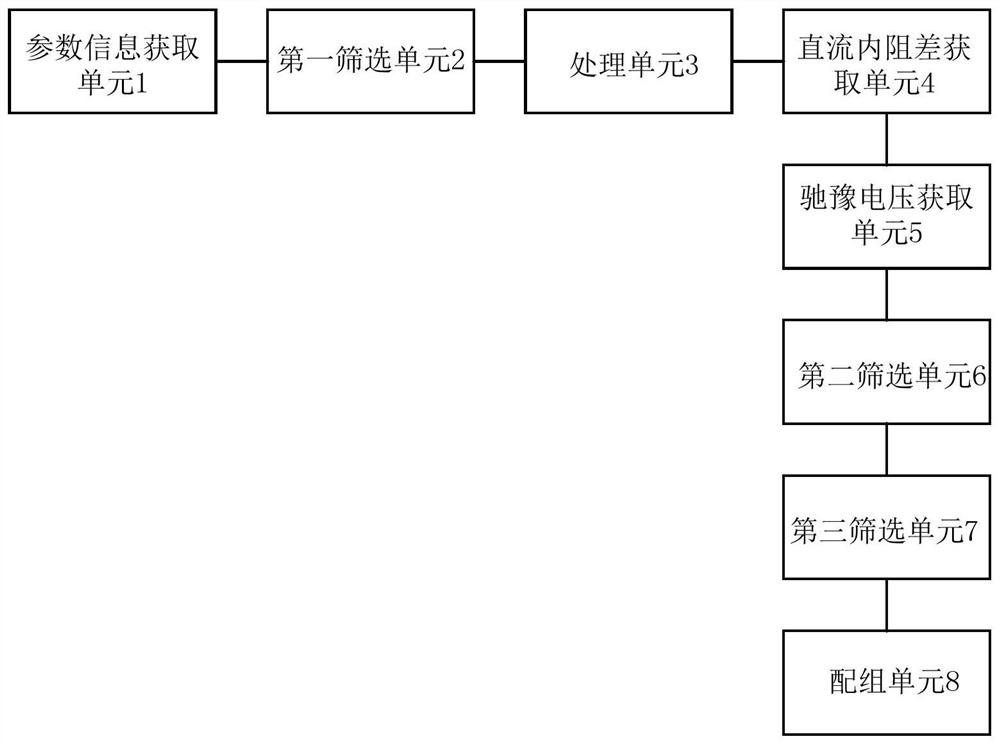

[0136] image 3 An assembly device for a lithium battery provided in Embodiment 2 of the present invention.

[0137] refer to image 3 , the device consists of:

[0138] The parameter information obtaining unit 1 is used to obtain the parameter information of the lithium battery, and the parameter information includes capacity, open circuit voltage, self-discharge rate and AC internal resistance;

[0139] The first screening unit 2 is used to screen a plurality of lithium batteries according to capacity, open circuit voltage, self-discharge rate and AC internal resistance respectively, to obtain a first lithium battery pack;

[0140] The processing unit 3 is configured to charge and discharge the first lithium battery pack to obtain the first DC internal resistance corresponding to the second lithium battery pack and the second DC internal resistance corresponding to the third lithium battery pack;

[0141] The DC internal resistance difference acquisition unit 4 is configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com