Practical iron plate cutting device for constructional engineering

A cutting device and construction engineering technology, which is applied in the field of construction engineering, can solve the problems of only forming a ring, the circle is not standard enough, and poor practicability, and achieve the effects of low manufacturing cost and maintenance cost, improved work efficiency, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

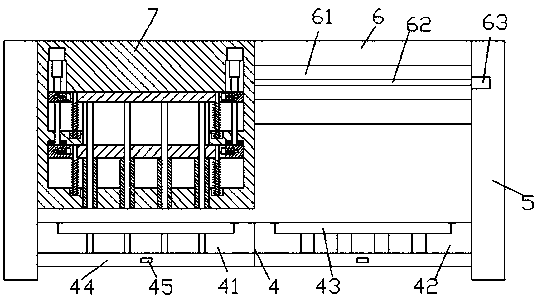

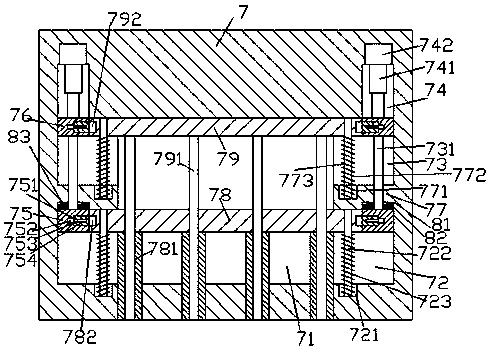

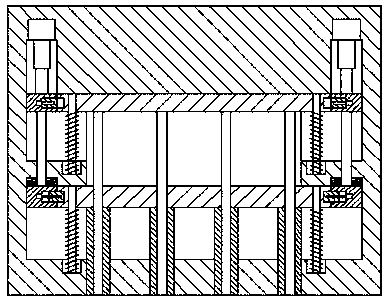

[0025] Such as Figure 1-Figure 8 As shown, a practical iron plate cutting device for construction engineering of the present invention includes a base frame and a cutting device 7, and a cavity 71 is provided inside the cutting device 7, and the left and right sides of the cavity 71 are oppositely provided with a second A chute 73, a fence 77 and a second chute 72, the cavity 71 is provided with a left and right extended first slide bar 79, and the left and right extended tail ends of the first slide bar 79 penetrate into the left and right sides respectively The first chute 73 of the first chute 73 is slidingly connected, and the second sliding rod 78 extending left and right is provided under the cavity 71, and the left and right extending tail ends of the second sliding rod 78 are inserted into the left and right sides The second chute 72 is slip-fitted and connected, and the bottom of the second slide bar 78 is provided with an annular stamping bar 781 extending downwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com