Cable traction wheel groove machining device

A cable traction and wheel groove technology, which is applied in the field of cable traction wheel groove processing devices, can solve the problems of waste of materials, long cycle time, high price, etc., and achieve the effects of reducing production costs, ensuring effective utilization, and ensuring resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with embodiment:

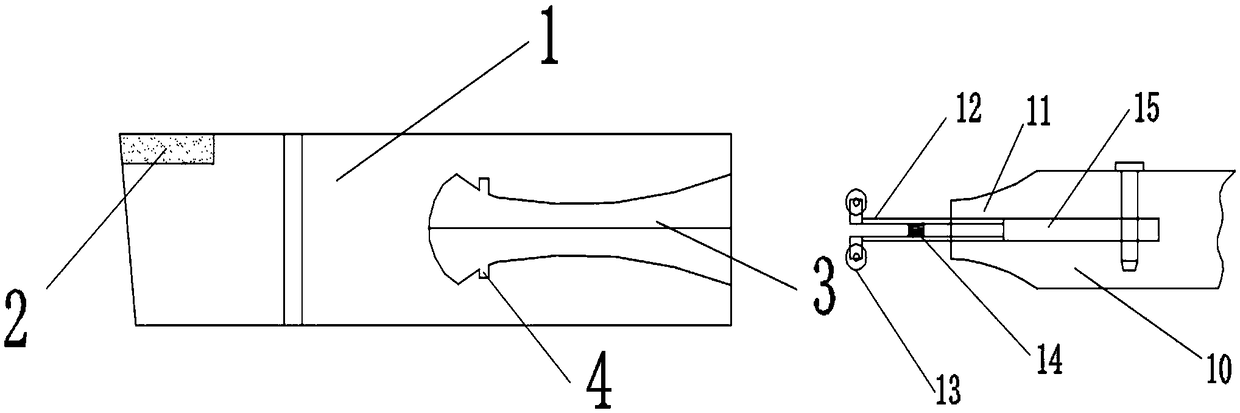

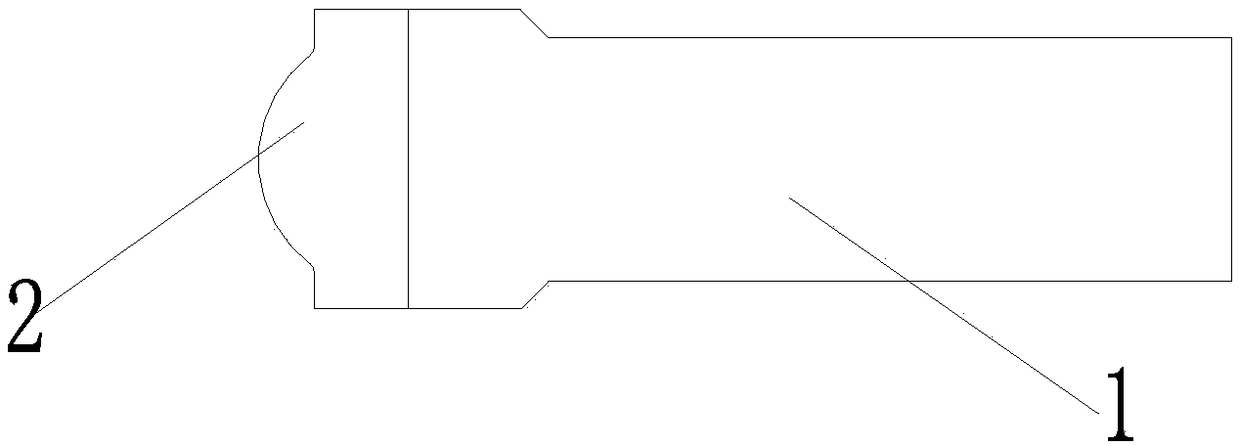

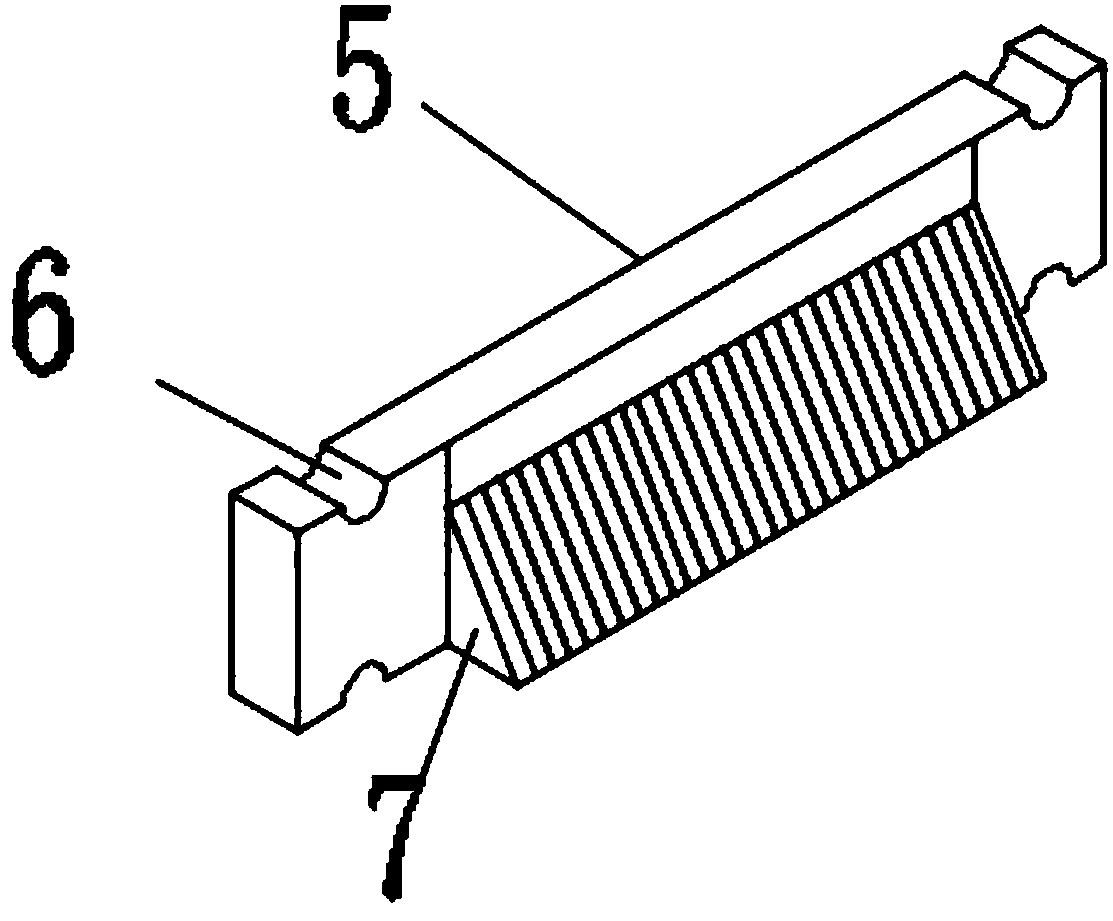

[0019] A cable pulley groove processing device, comprising a tool body 1, a connecting rod 10, a blade 2 is provided at one end of the tool body 1, and an arc-shaped fixing groove 3 is opened in the middle of the tool body 1, so that The arc-shaped fixing groove 3 is connected with the other end of the cutter body 1, the cutter body 1 is connected with the connector at one end of the fixing frame through the arc-shaped fixing groove 3, and the inner side of the arc-shaped fixing groove 3 has two ends There are grooves 4 on the sides, and one end of the connecting rod 10 is connected with a fixed rod 11 through a pin shaft. The fixed rod 11 includes two elastic support rods 12, and the ends of the two elastic support rods 12 are respectively movably connected. A rolling shaft 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com