Filling machine buffer tank

A buffer tank and filling machine technology, applied in the field of medicine, can solve the problems that the fluctuation of the liquid level in the buffer tank has a great influence, affect the quality and efficiency of canning, and achieve the effect of increasing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

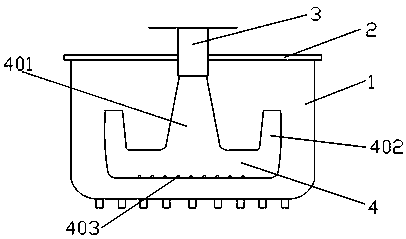

[0017] Such as figure 1 A filling machine buffer tank shown includes a tank body 1, the top of the tank body is provided with a cover plate 2 with a through hole, and a liquid inlet pipe nozzle 3 extends into the tank body through the through hole of the cover plate. The bottom of the nozzle 3 of the liquid pipe is connected to the mountain-shaped shunt pipe 4, which includes a connecting pipe 401 in the middle and liquid outlet pipes 402 located on both sides of the connecting pipe, and a number of micropores 403 are provided at the bottom.

Embodiment 2

[0019] With reference to Example 1, the height of the outlet pipe is higher than that of the connecting pipe, the connection between the horizontal pipe of the mountain-shaped shunt pipe and the longitudinal connecting pipe and the outlet pipe is an R angle with a radian, and the liquid inlet pipe The cross-sectional area of the bottom of the nozzle ≤ the cross-sectional area of the top of the connecting pipe ≤ the cross-sectional area of the bottom of the connecting pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com