Marine shipping unloading platform

A platform and ship technology, applied in the field of ship shipping and unloading platforms, can solve problems such as inconvenience and low work efficiency, and achieve the effects of reducing occupied space, increasing work efficiency, and increasing spring buffer force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

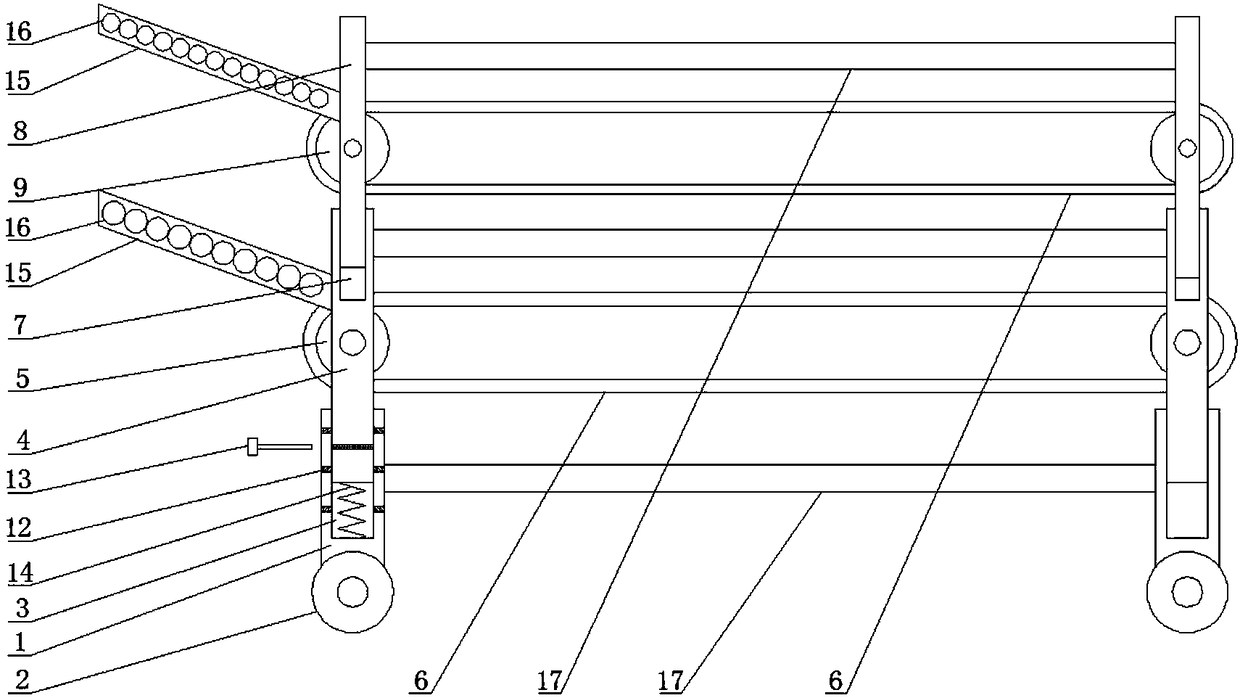

[0016] Such as figure 1 As shown, a shipping unloading platform for ships includes two groups of base columns 1 placed oppositely left and right, and each group includes two base columns placed oppositely front and back; and the lower end of the base columns 1 is also equipped with a roller 2 , and the upper end of the base column 1 is also provided with a first-level lifting groove 3; and a first-level column 4 that can move up and down is also installed in the first-level lifting groove 3; The first-stage transmission roller 5, and the conveyor belt 6 is installed between the first-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com