A method for overall installation of equipment track

An overall installation and track technology, which is applied in construction, infrastructure engineering, manufacturing tools, etc., can solve problems such as large installation volume, burial deviation, and bolt displacement, so as to improve work efficiency, simplify track installation work, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

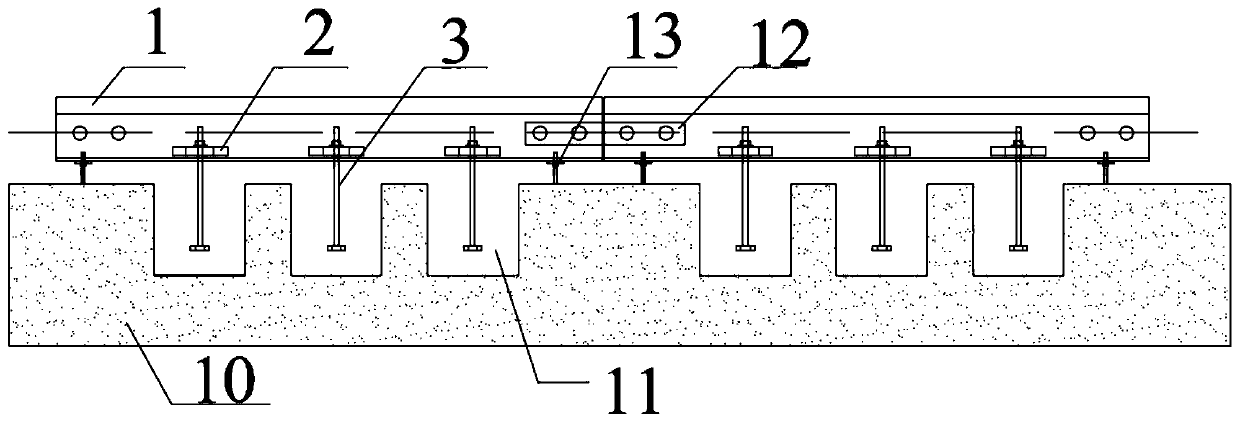

[0021] The present invention is illustrated below in conjunction with the accompanying drawings.

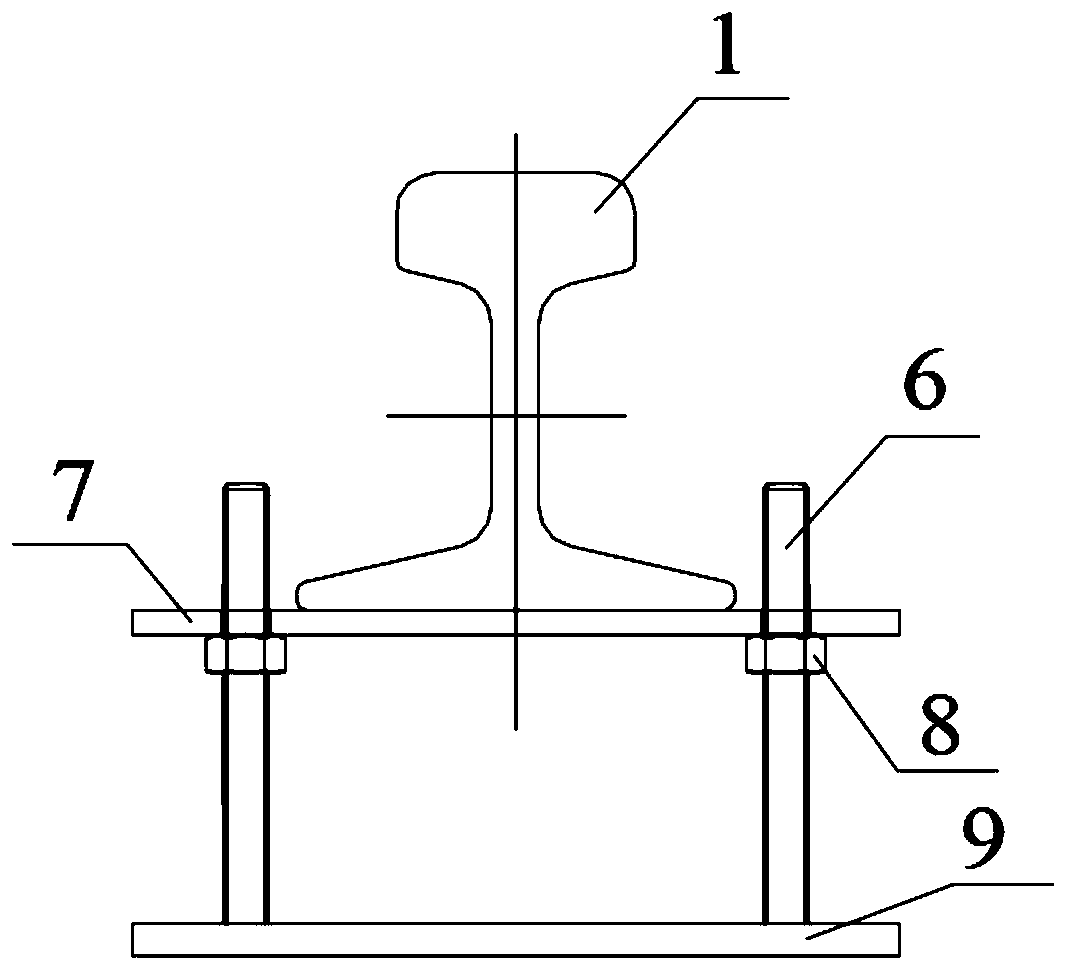

[0022] Such as Figure 1 to Figure 3 As shown, a method for overall installation of equipment tracks includes the following steps:

[0023] Step 1. When the track foundation 10 is poured, a bolt reserved hole 11 is reserved according to the bolt installation position of the fixed track 1;

[0024] Step 2: Install the track fixing device on the track 1, and the fixing bolt 3 of the track fixing device hangs down naturally under the track 1;

[0025] Step 3, install the track adjusting device 13 that plays a temporary fixing role at both ends of the track 1, and adjust the position of the track 1 through the track adjusting device 13;

[0026] Step 4, using a measuring instrument to perform positioning correction on the installation position of track 1;

[0027] Step 5: After the installation position of the track 1 is adjusted, pour the bolt reserved holes 11 on the track found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com