Motor with electrically slipping rotor spindle and purpose

A technology of rotor shaft and motor, applied in the field of transmission system, can solve the problems of enlarged transmission system space, increased operation and maintenance workload, complicated control, etc., and achieves the effect of simplifying installation work, reducing maintenance workload and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

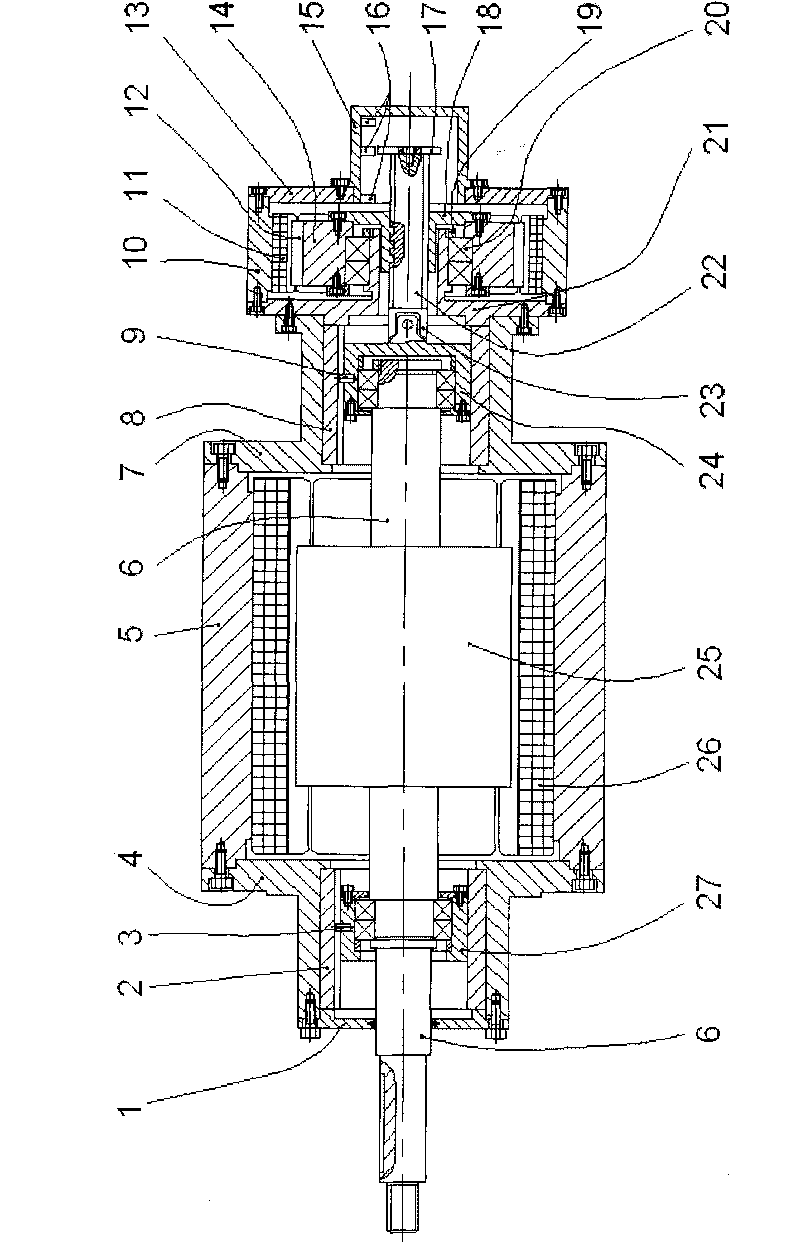

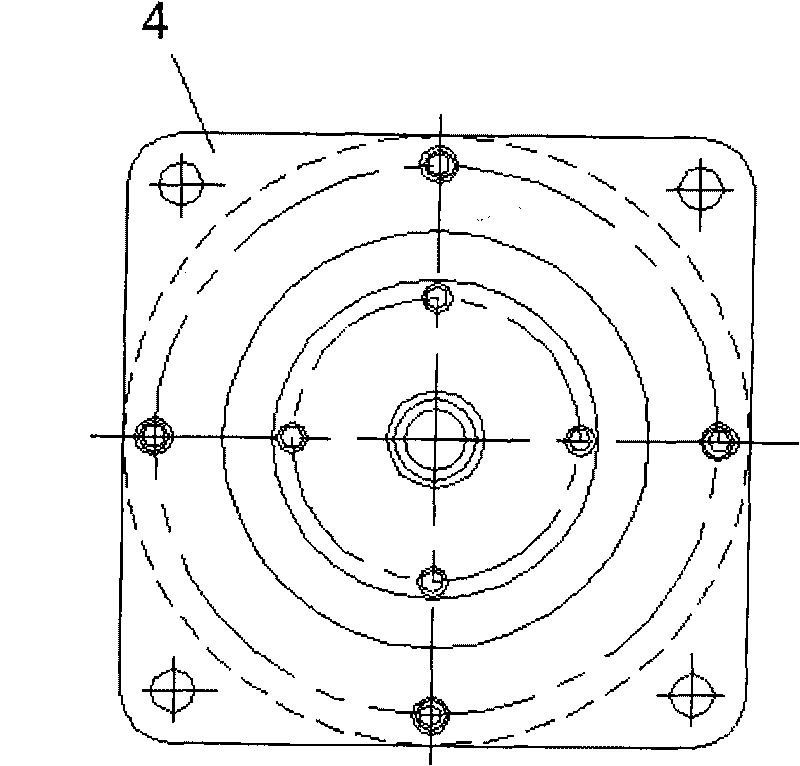

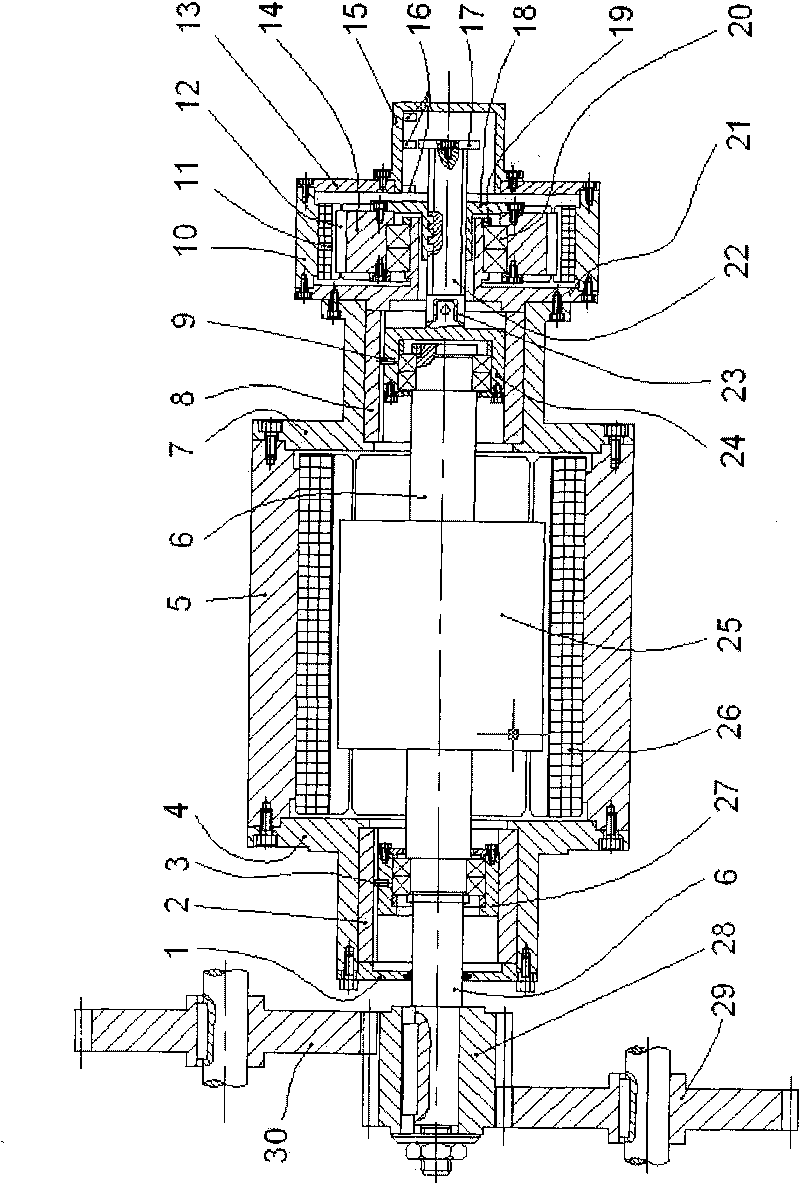

[0017] The motor for electric sliding of the rotor shaft provided by the invention comprises a set of motor stator and motor rotor, and a set of sliding driving mechanism. One end of the rotor shaft of the motor rotor is installed with a drive gear to output torque, and the other end is installed with a slip drive mechanism. The sliding drive mechanism is mainly composed of a screw rod and a nut, an auxiliary stator and an auxiliary rotor, wherein the nut is coaxially installed on the auxiliary rotor. When the auxiliary rotor drives the nut to rotate, the screw rod matched with the nut will move axially and linearly, and finally the motor rotor shaft will slip axially. The axial slip position of the rotor shaft is detected by multiple position sensors installed at the end of the motor, and the rotor shaft of the motor can slip to a certain position through the control of the slip drive mechanism.

[0018] The motor is suitable for multi-transmission chain mechanical equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com