An oil circuit distribution valve for large flow hydraulic system

A hydraulic system and oil circuit distribution technology, applied in the field of hydraulic valves, can solve the problems of high price, increased cost of electronic control, system complexity, and cost pressure, and achieve the effect of compact size, simple structure, and reduced difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

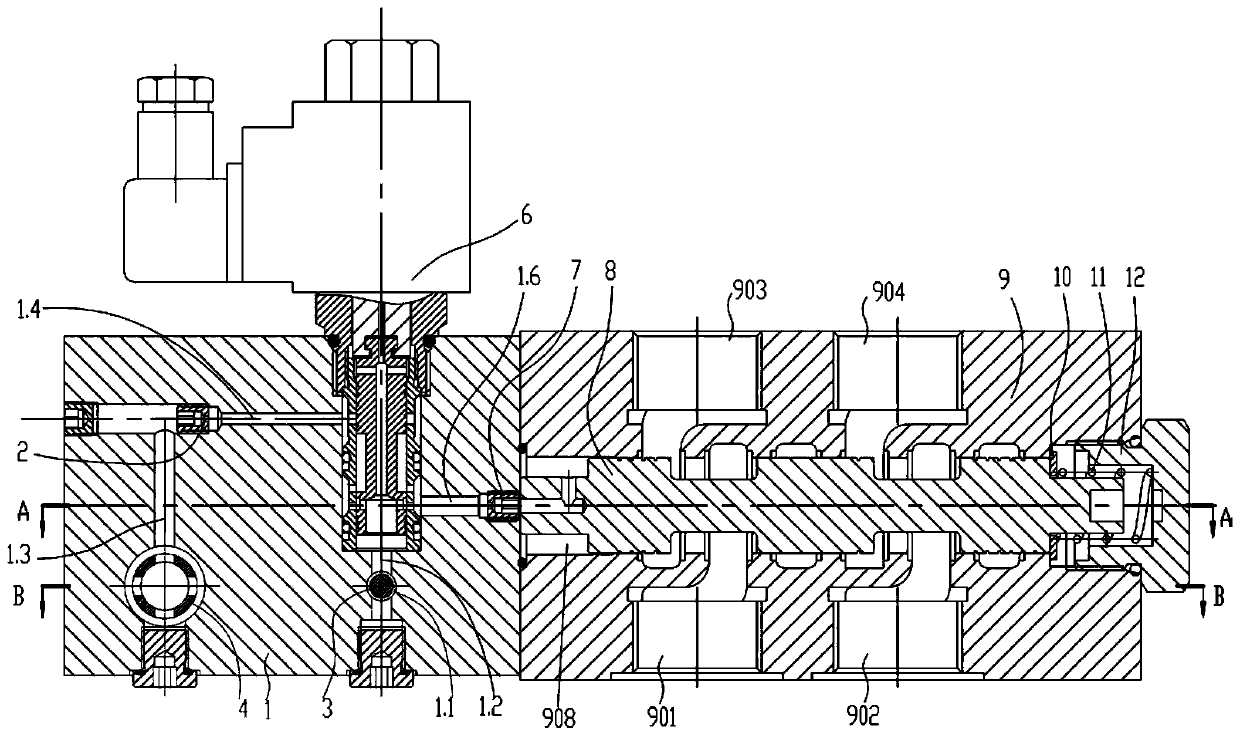

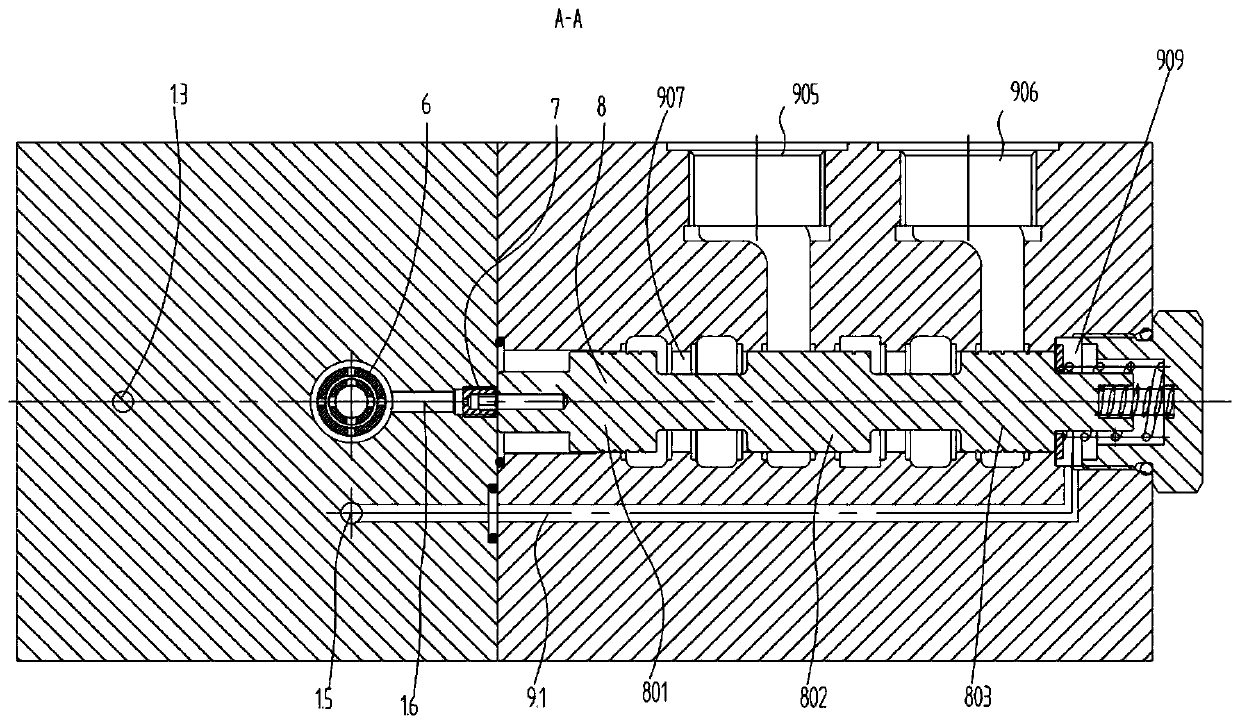

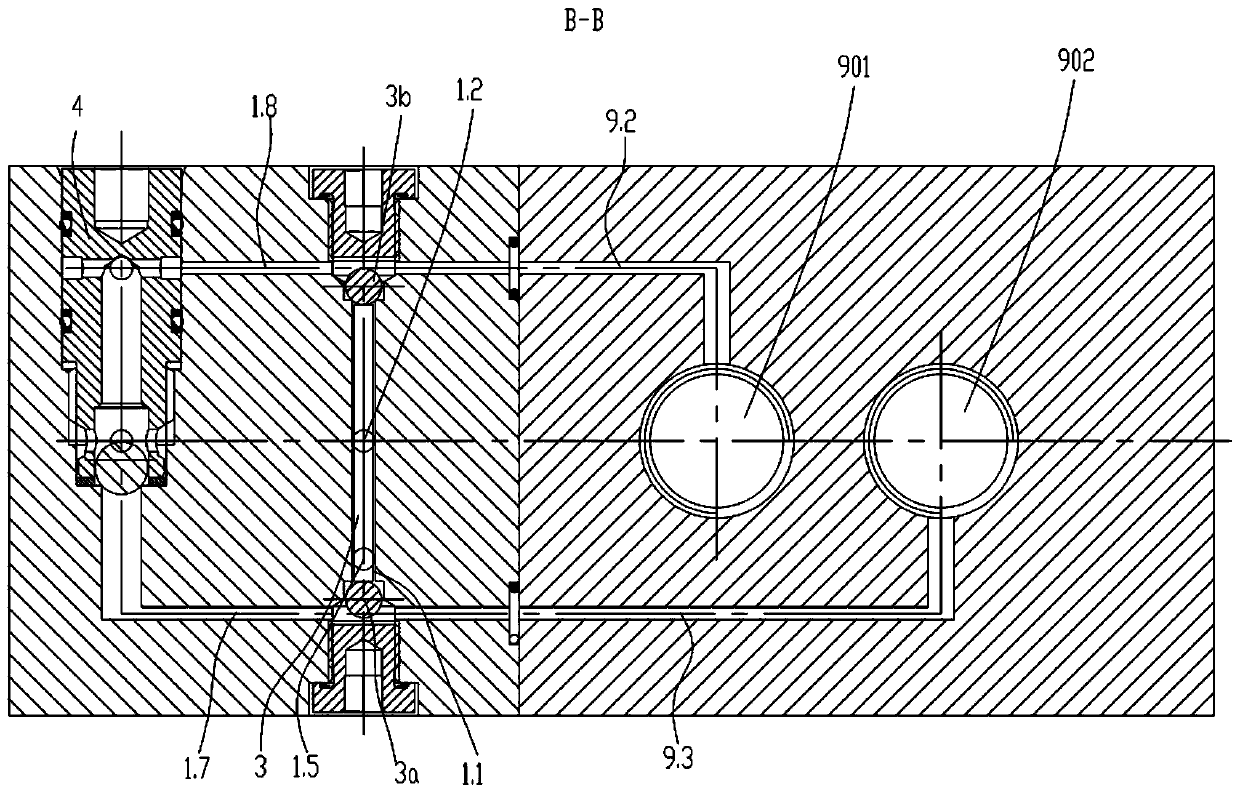

[0021] see Figure 1-6 , the present invention provides an oil distribution valve for a large flow hydraulic system, including a P1 oil port 901, a P2 oil port 902, an A oil port 903, a B oil port 904, a C oil port 905, and a D oil port 906 The valve body 9 is provided with a left and right through installation hole 907 in the valve body 9, and the main valve core 8 for controlling the on-off of the oil port is slidably connected in the installation hole 907; on the side of the main valve core 8 A first shoulder 801, a second shoulder 802, and a third shoulder 803 are sequentially provided along its axial direction from left to right, and an end cover 1 is installed on the left end of the mounting hole 907 on the valve body 9, so that A control cavity 908 is formed between the first shoulder 801 and the end cover 1; a screw plug 12 is installed on the right end of the installation hole 907 on the valve body 9, and the third shoulder 803 and the screw The oil return cavity 909...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com