A conveniently installed automobile brake disc structure

A technology that is easy to install and brake disc, applied in the direction of brake disc, brake components, brake type, etc., can solve the problem of inconvenient installation, achieve the effect of convenient heat dissipation and avoid wear and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

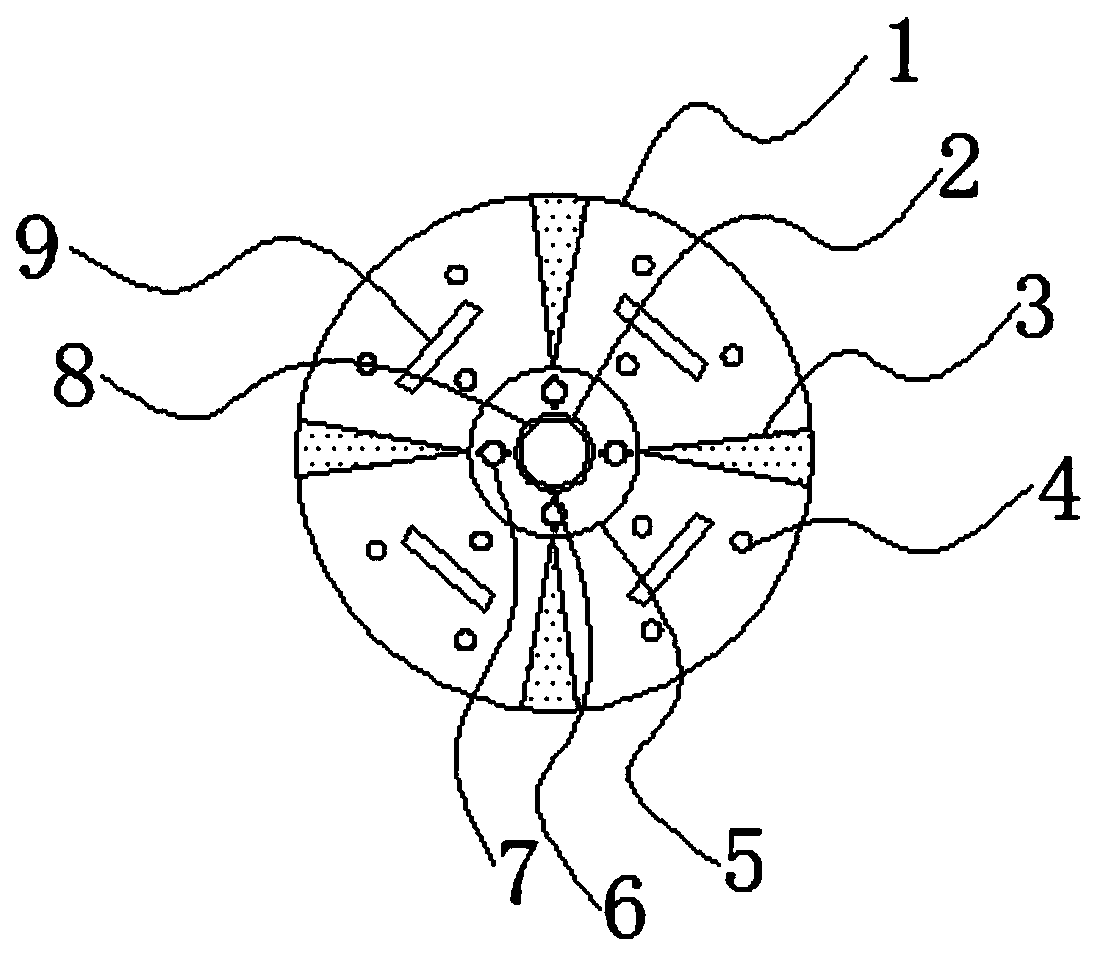

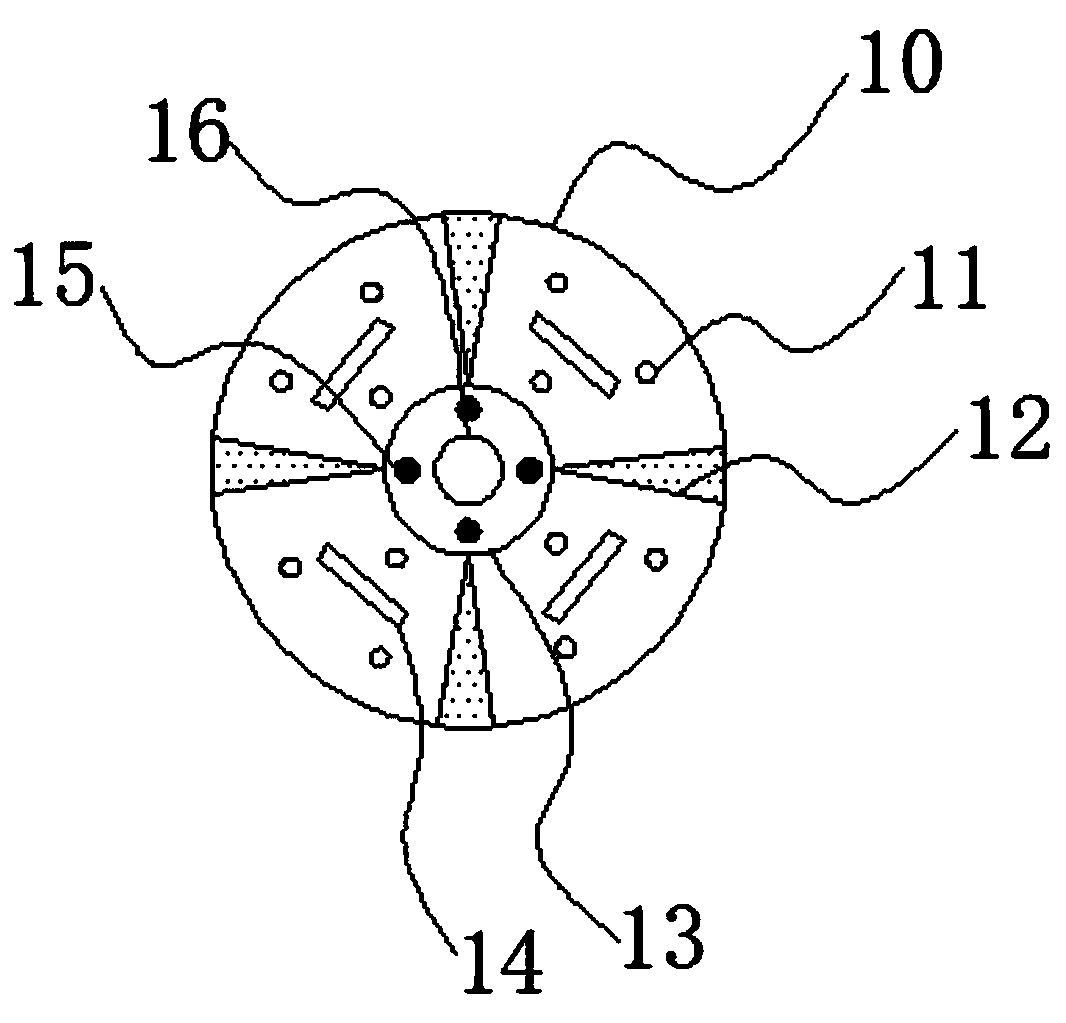

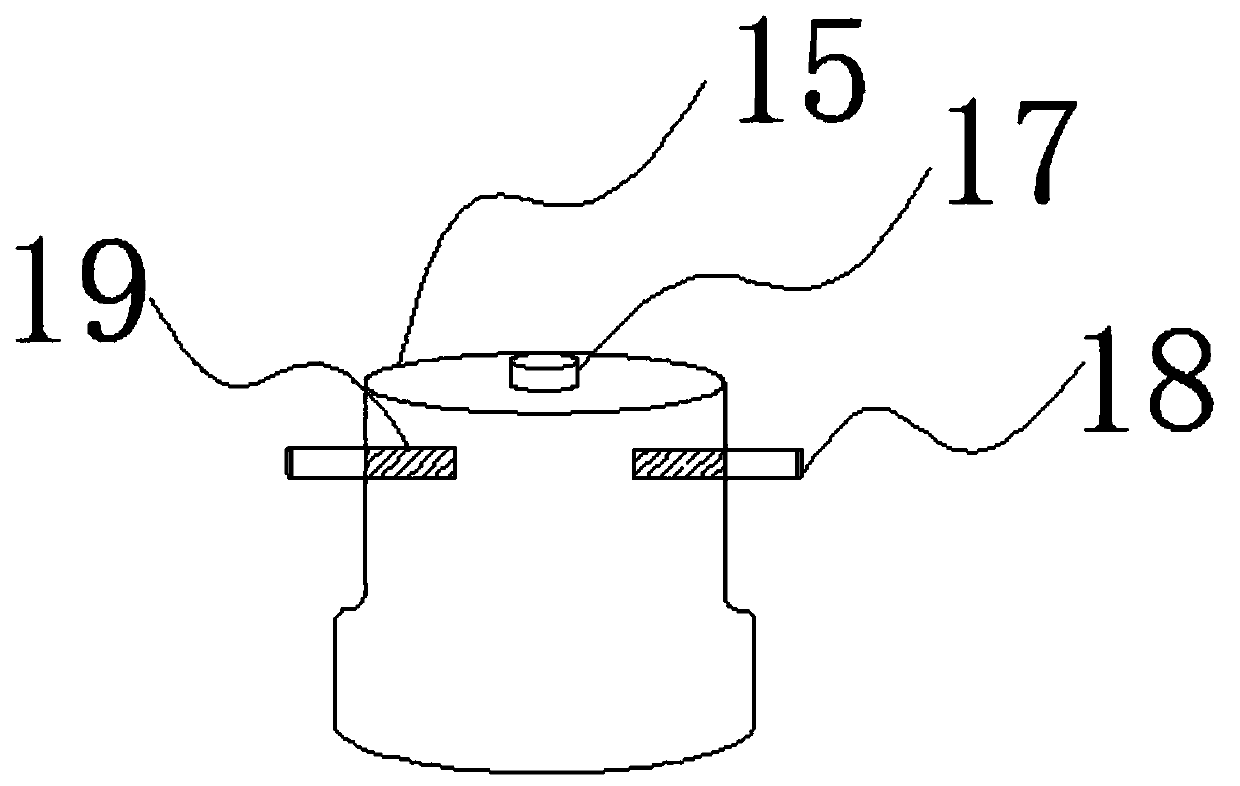

[0018] see Figure 1-4 , the present invention provides a technical solution: a brake disc structure for automobiles that is convenient to install, including a first brake disc 1, an outer ring 2, a first row of waste grooves 3, a first heat dissipation hole 4, a first connecting plate 5, Inner ring 6, clamping hole 7, connecting shaft placement slot 8, first heat dissipation block 9, second brake disc 10, second heat dissipation hole 11, second row of waste grooves 12, second connection plate 13, second heat dissipation block 14. It consists of a block 15, a connecting shaft 16, a button 17, a retractable rod 18, a retractable rod placement groove 19, a snap-in pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com