Flat plate type vacuum hollow glass lamp

A glass lamp and flat-panel technology, applied in the field of lighting, can solve problems such as short service life, low quality, and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention by the following examples, it should be pointed out that the listed examples should not be construed as a reference to the present invention.

[0020] Invention Limitations.

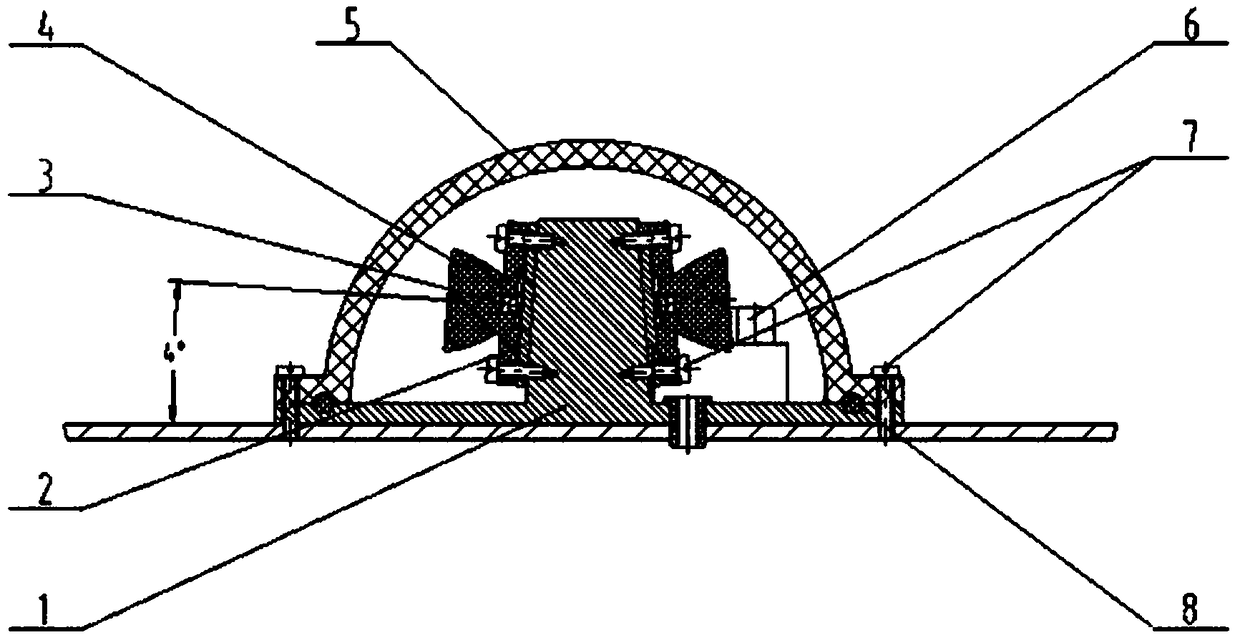

[0021] combine figure 1 As shown, a flat vacuum hollow glass lamp is composed of a lamp base 1, a lamp holder 2, a radiator 4, an LED lamp board 6 and a lampshade 7 connected in sequence. The lamp holder 2 is provided with a circuit board 3, and the LED lamp board 6 is There are LED lamp beads 61 fixed on the radiator 4 through an LED lamp board accommodation slot 5 , the inner wall of the radiator 4 is provided with a smoke flushing heat dissipation channel, and the outer wall of the radiator 4 is provided with finned heat sinks 41 .

[0022] Further, the interior of the radiator 4 is a cylindrical cavity 44 , and two symmetrically distributed grooves 441 are provided on the inner wall of the cylindrical cavity 44 .

[0023] Furthermore, the lamp holder 2 is a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com