Method for checking service life of liquid-filled sensitive element and special tool part therefor

A technology for sensitive components and tooling parts, which is applied in the field of accelerated assessment of the life of sensitive components, can solve problems such as long time periods, and achieve the effects of good practicability, good economy, and easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

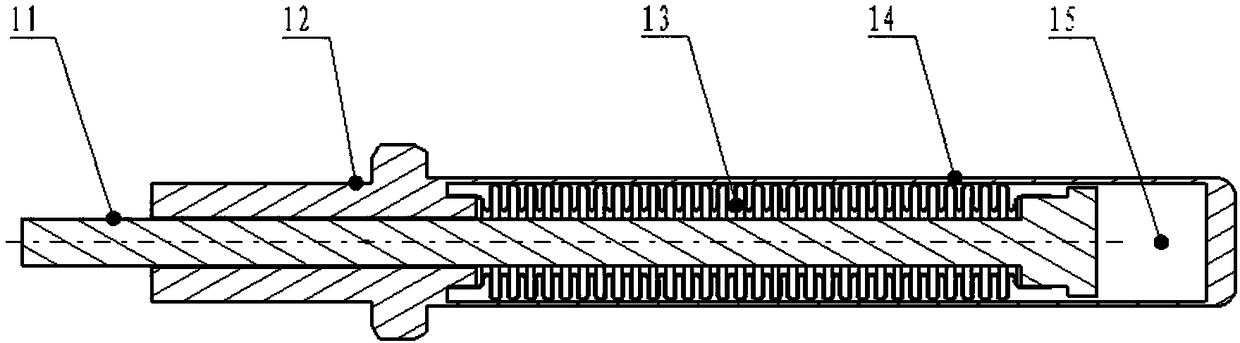

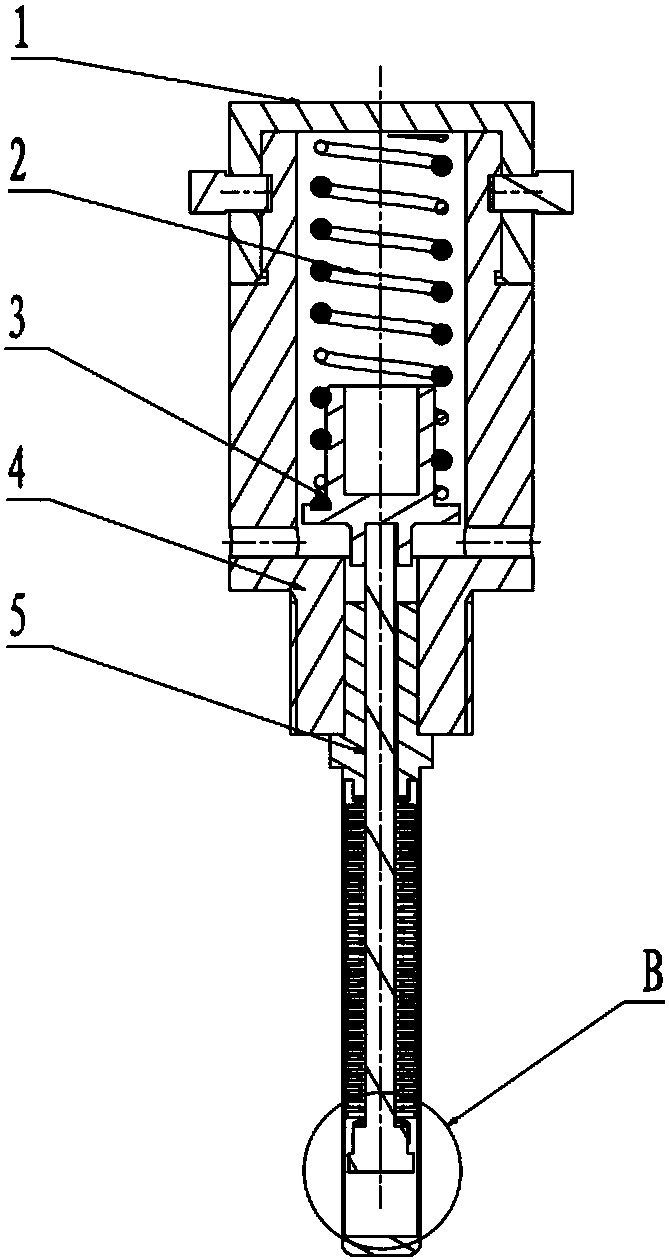

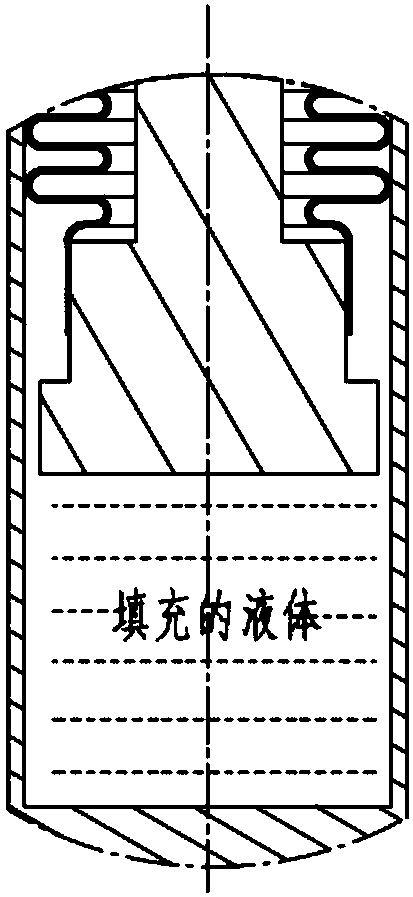

[0017] see figure 1 , figure 2 , image 3 , because the liquid-filled sensitive element is airtight and vacuum-like, its life assessment can be equivalent to the assessment of the leakage of the sensitive element within a certain period of time, and the leakage within the specified time is proportional to the leakage rate of the sensitive element. The leakage rate of the sensitive element is changed by the uniform distribution force of the liquid, increasing the uniform distribution force can achieve the goal of accelerating the assessment of the calendar year life of the sensitive element. The purpose of increasing the uniform force can be achieved by applying a concentrated force to the sensitive element. The following is the specific implementation method:

[0018] 1) Calculate and analyze the influence factors of the life equivalent assessment of liquid-filled sensitive elements. According to: (uniform force P1) × (effective force bearing area S) = (concentrated force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com