Composite plate, ground assembly and laying method of ground assembly

A composite board and ground technology, applied in the direction of floors, elastic floors, buildings, etc., can solve the problems of poor foot feel of composite boards, difficult batch processing, complex structure of connecting parts, etc., to achieve rapid construction, easy batch processing, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

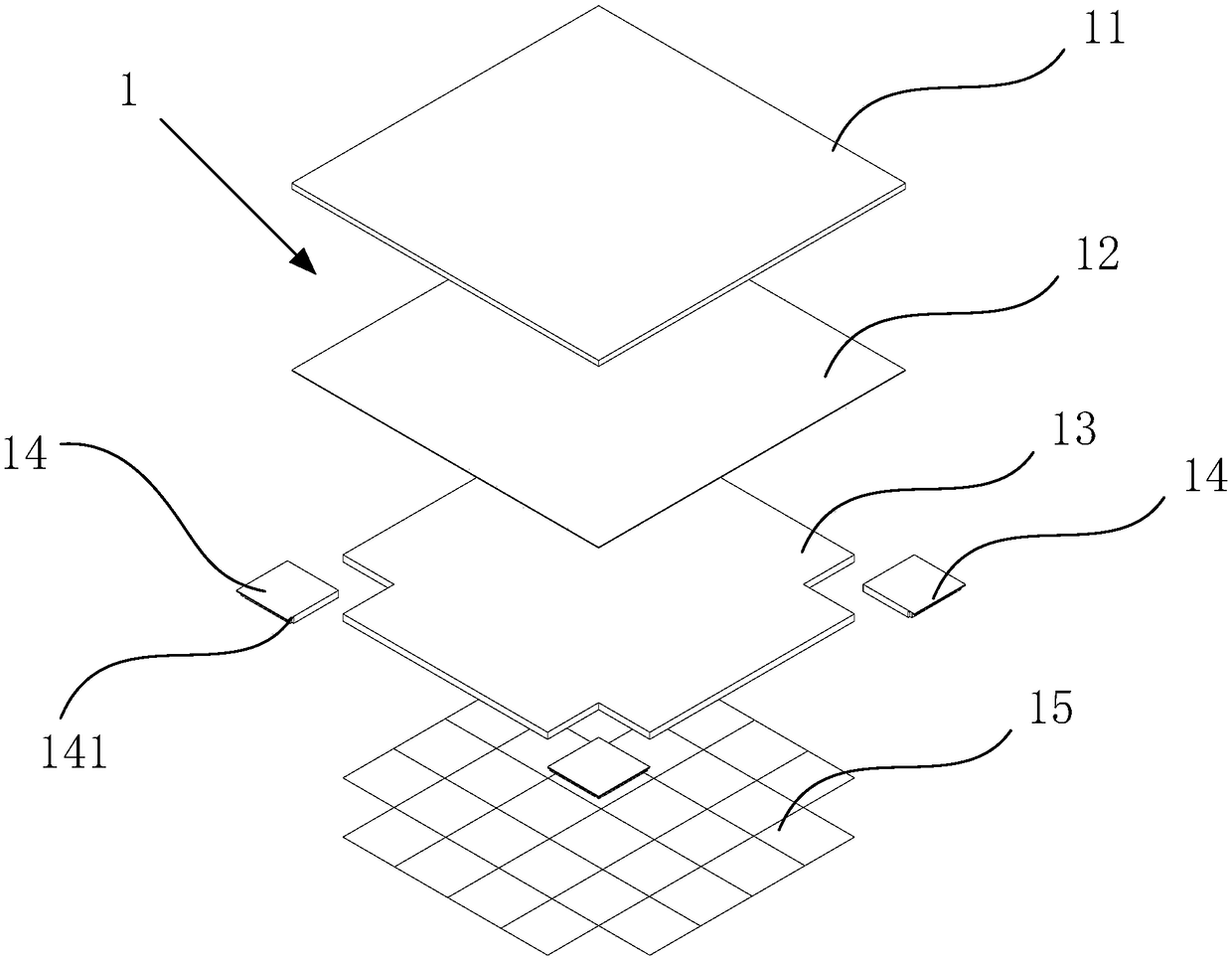

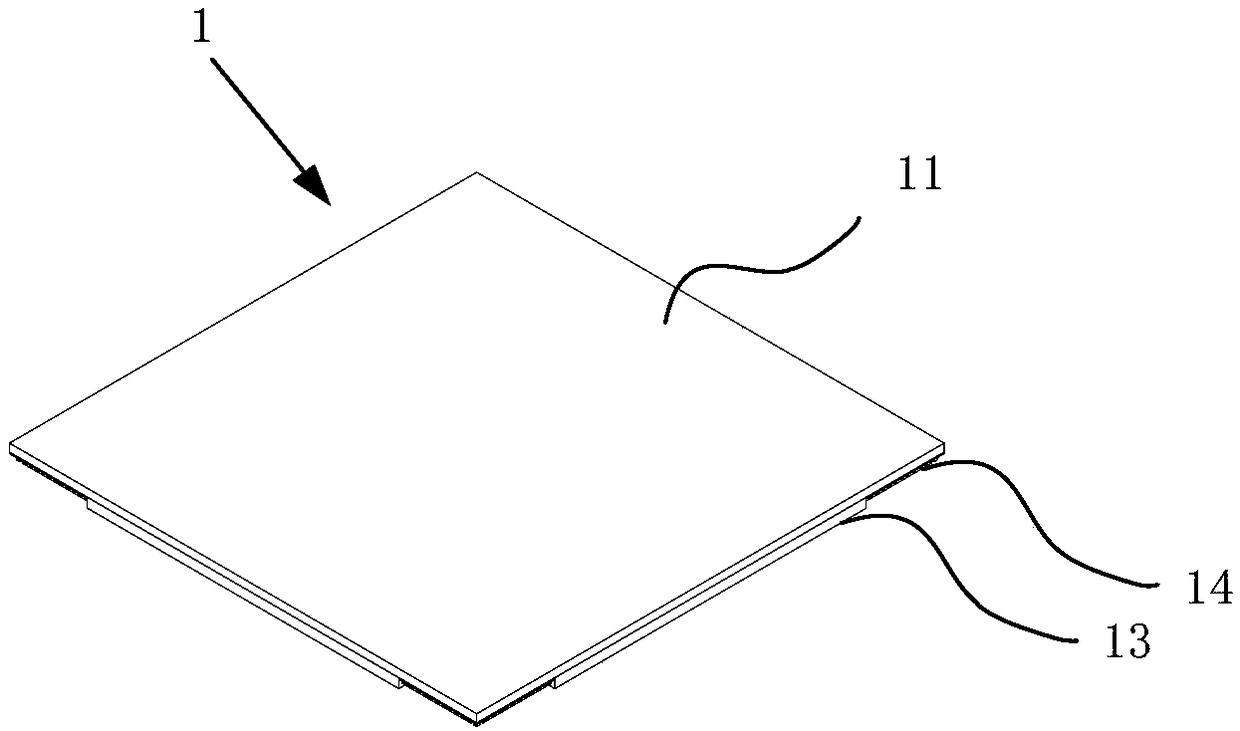

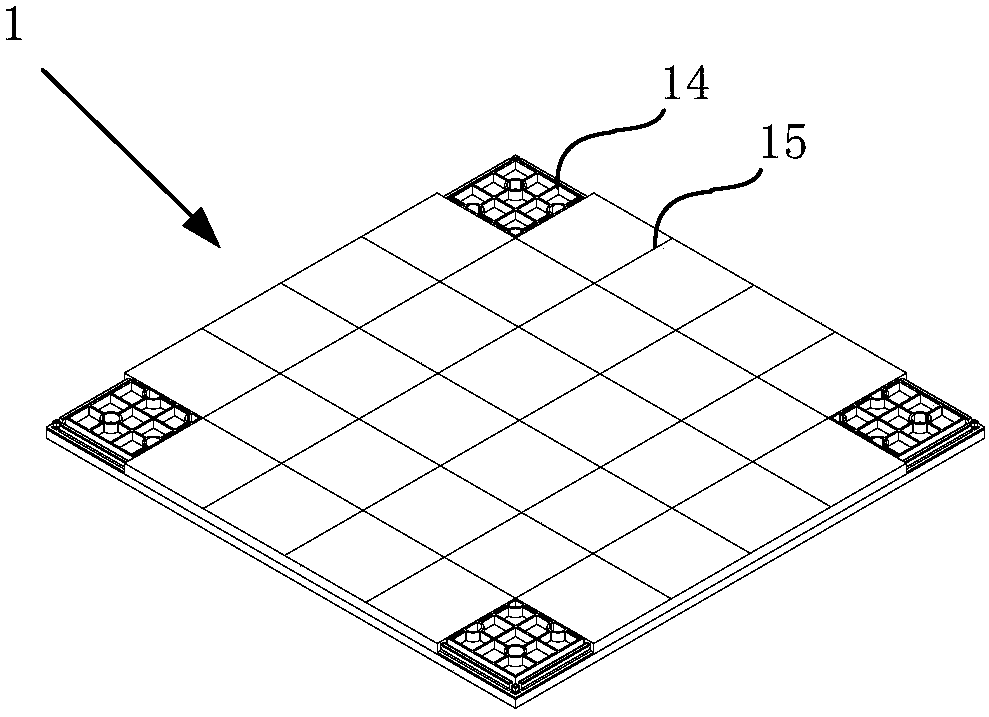

[0030] like figure 1 Shown is a schematic structural view of a composite panel 1 of the present invention, including: a decorative surface layer 11, an adhesive layer 12, a solid base plate 13, and one or more structural members 14, and the decorative surface layer 11 passes through the adhesive layer. The adhesive layer 12 is combined with the solid base plate 13, at least one corner of the solid base plate 13 is provided with a notch 131, the structural member 14 is embedded in the notch 131 and passes through the adhesive layer 12 and the decoration The surface layer 11 is compounded, and the edge position of the structural member 14 away from the notch 131 is provided with a plug connector 141 .

[0031] Specifically, the decorative surface layer 11 is used to display decorative textures, and the decorative surface layer 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com