Gear device used for railway vehicle

A technology for gear devices and railway vehicles, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc., which can solve the problem of low degrees of freedom of gear devices and achieve the effect of increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

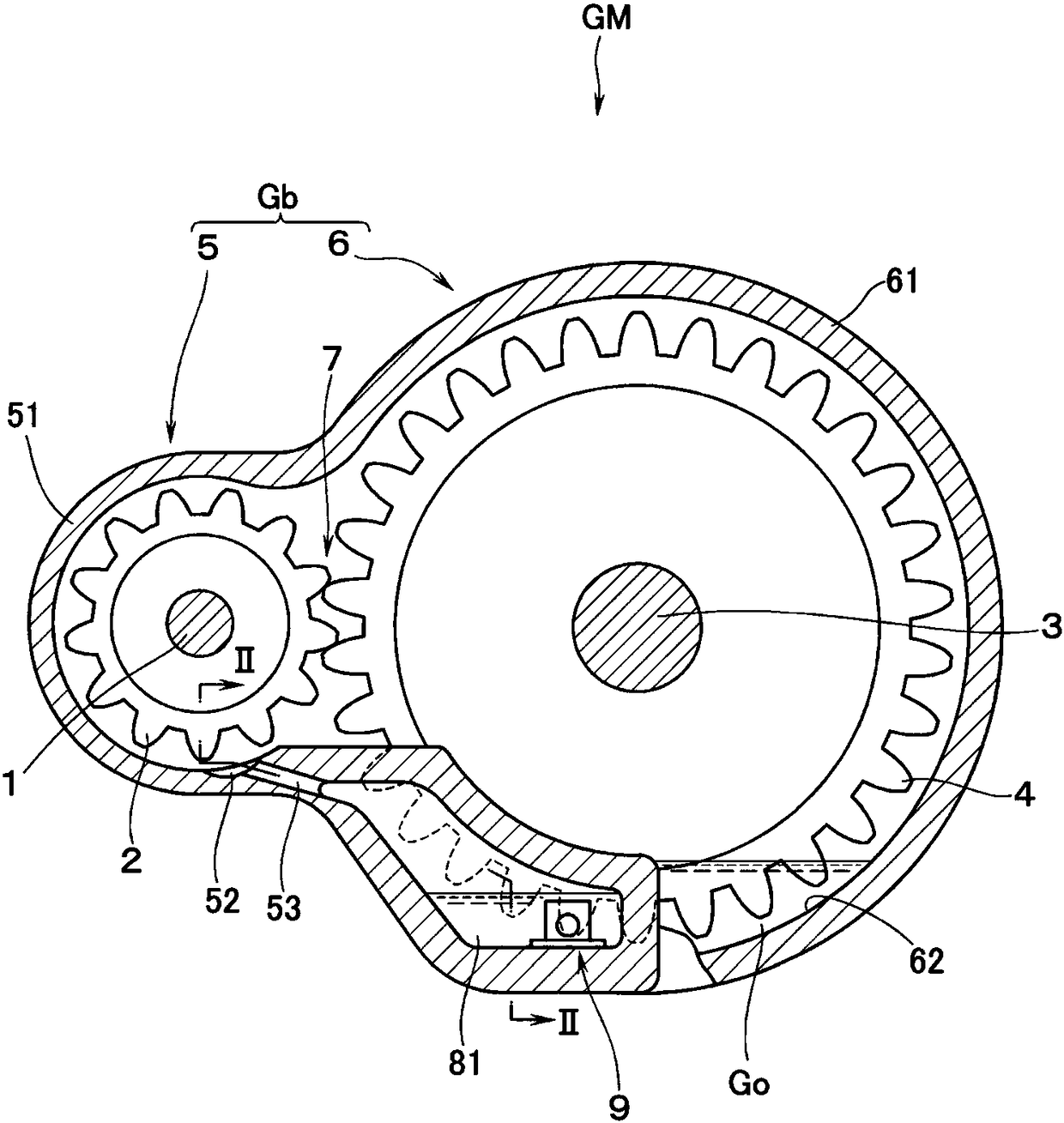

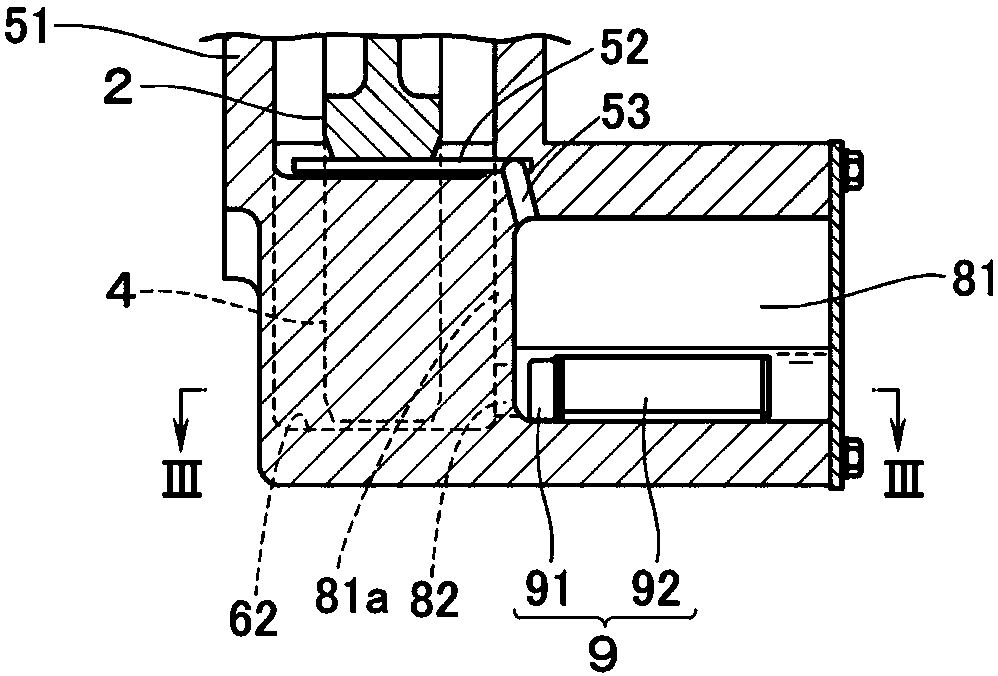

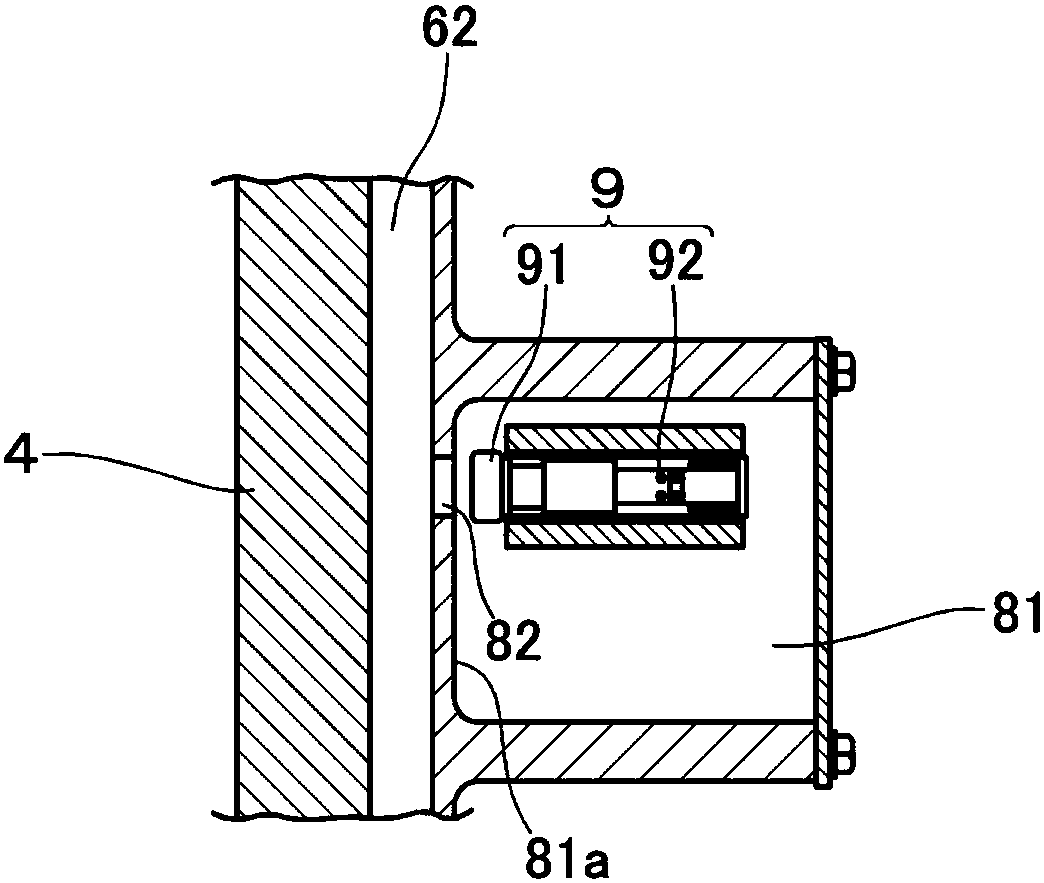

[0015] Hereinafter, embodiments of the gear device for railway vehicles according to the present invention will be described with reference to the drawings. In the following, the installation posture on the trolley is indicated figure 1 As a reference, terms representing directions such as "up" and "down" are used.

[0016] refer to figure 1 , GM is the gear device for railway vehicles according to this embodiment. The gear unit GM includes the gear case Gb of the carriage provided outside the drawing. In the gearbox Gb, a pinion gear 2 fixed to an input shaft 1 of an unillustrated electric motor (drive source) via a bearing (not shown) and a large gear 4 fixed to an axle 3 via a bearing (not shown) are connected to each other. In a horizontally engaged state, the pinion gear 2 and the bull gear 4 are accommodated. Well-known components and elements can be used other than the gear case Gb constituting the gear unit GM, and therefore detailed description including these wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com