Electric adjustable-angle spraying pipe orifice

A technology for adjusting angles and nozzles, which is applied to cutting equipment, agricultural machinery and tools, and applications, and can solve inaccurate, laborious, and inconvenient problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

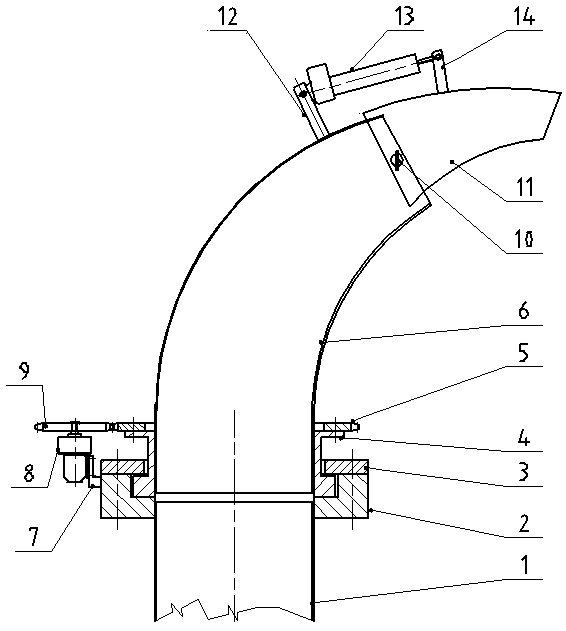

[0006] The invention consists of a volute discharge body (1), a base (2), a gland (3), a hollow shaft (4), a large gear (5), a rotating discharge pipe (6), a bracket (7), and a reduction motor (8), pinion (9), half shaft (10), live feed port (11), rear support (12), electric push rod (13), front lug (14), etc., base (2) It is fixed on the volute discharge body (1), the hollow shaft (4) is installed in the base (2), the gland (3) is fastened on the base (2) by bolts, and the hollow shaft (4) can be mounted on the base ( 2) Internal rotation, the large gear (5) is installed on the hollow shaft (4), the rotating discharge pipe (6) is fixed in the hollow shaft (4), the bracket (7) is fixed on the base (2), and the reduction motor ( 8) Fixed on the bracket (7), the pinion gear (9) is installed on the reduction motor (8), the pinion gear (9) meshes with the big gear (5), and the feed opening (11) is hinged through the half shaft (10) On the rotating discharge pipe (6), the rear sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com