Tool clamp for bamboo plate processing

A technology for clamping and lifting plates, applied in sugarcane machining, decorative arts, mechanical equipment, etc., can solve the problems of inability to realize the rotation of bamboo plates, inability to fix the bamboo plates, affecting processing, etc., and achieves simple structure, convenient processing, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

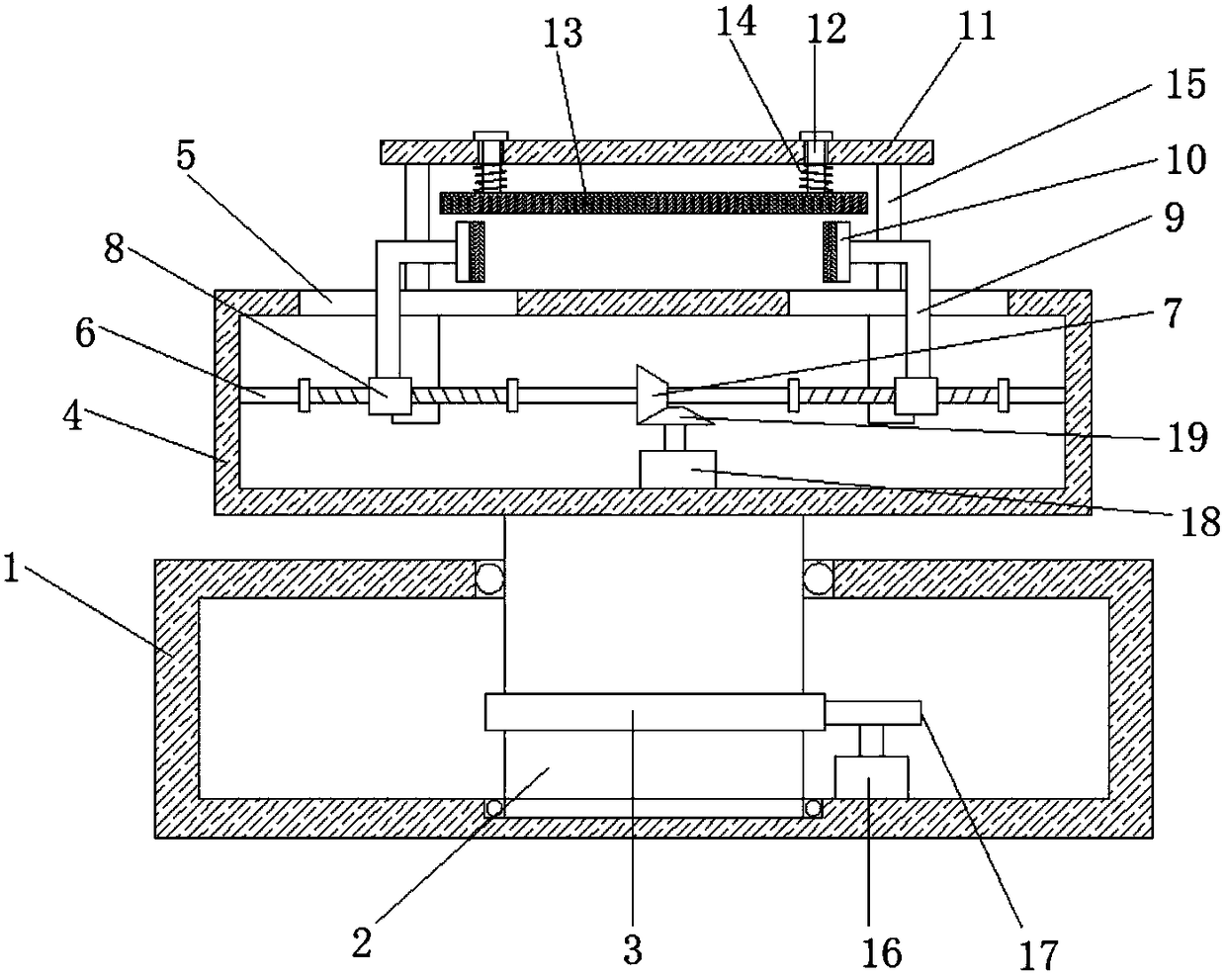

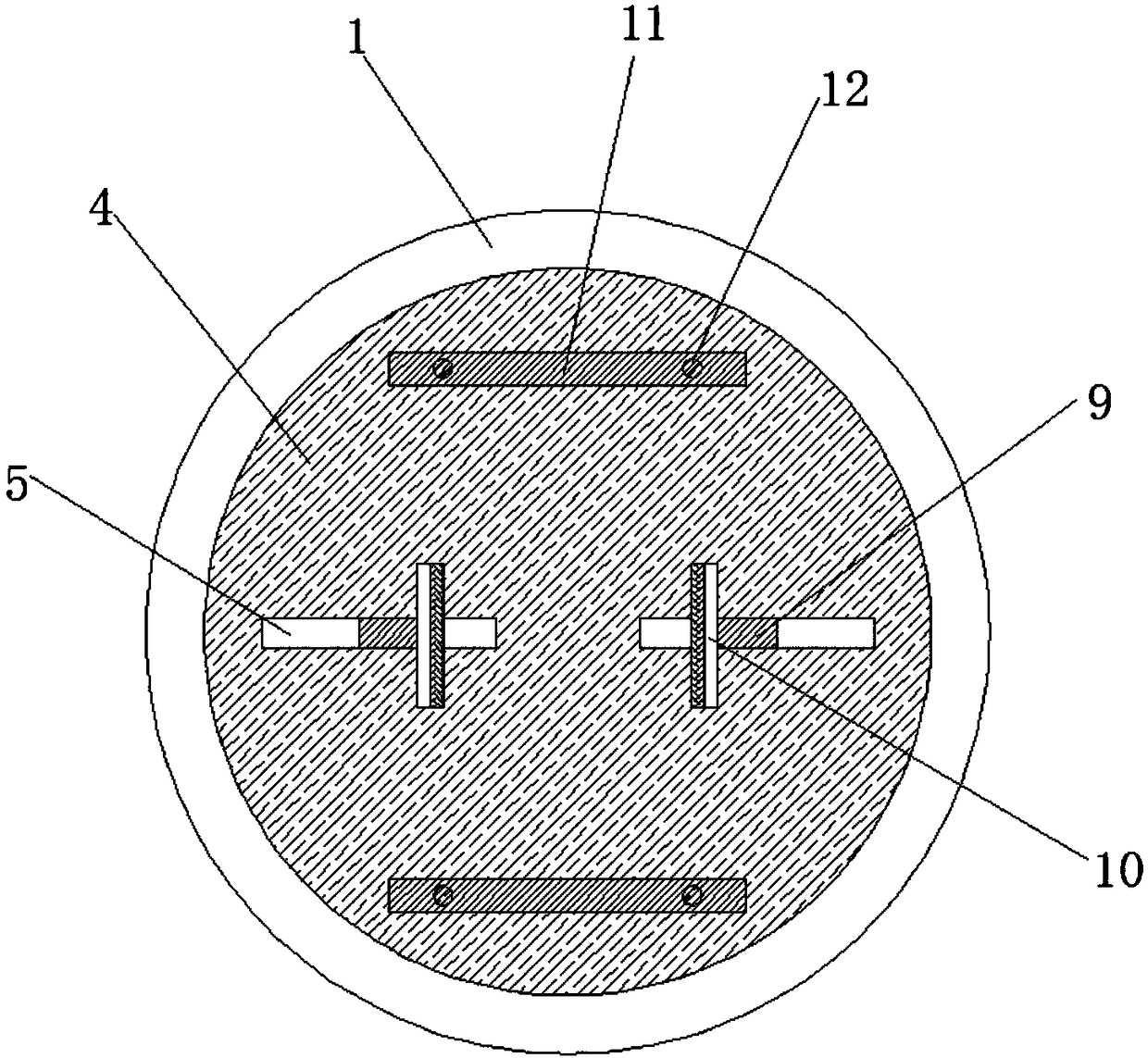

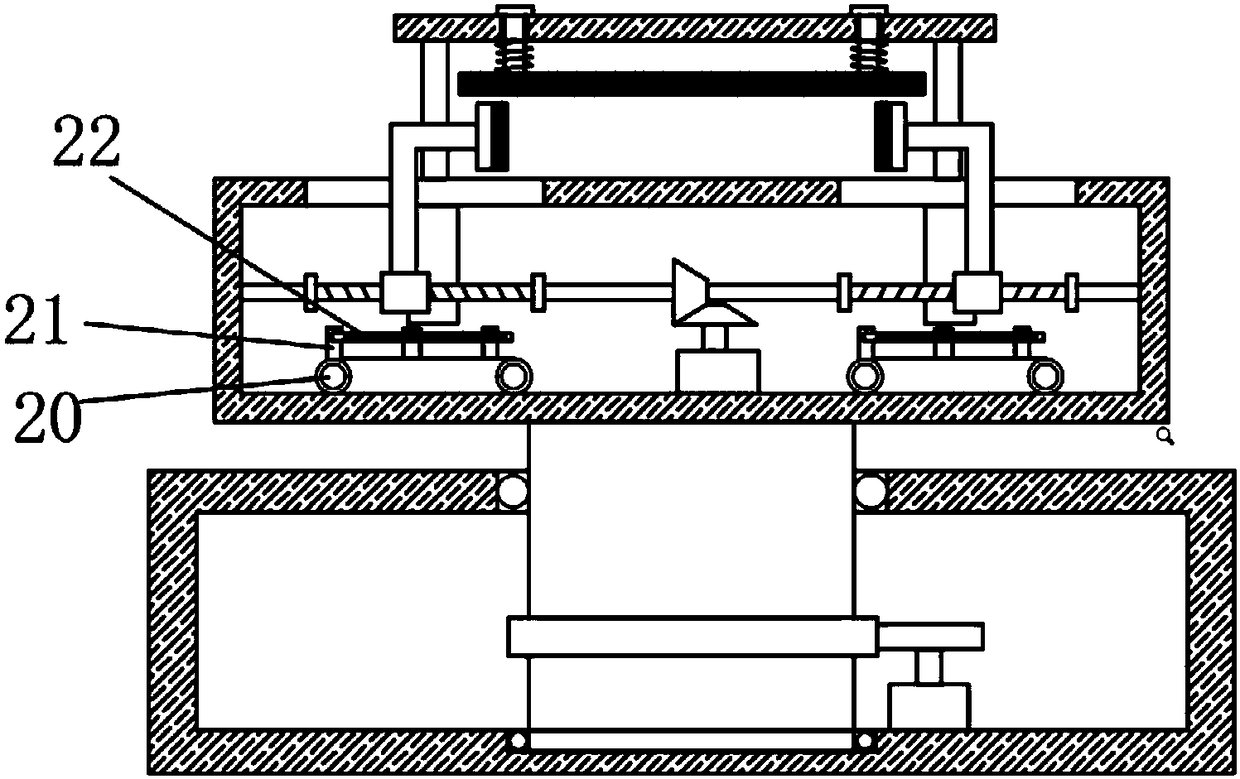

[0017] refer to Figure 1-2 , a tooling fixture for processing bamboo boards, comprising a base 1, the base 1 is a cavity structure, and a vertical support shaft 2 is installed between the center of the top wall and the bottom wall of the base 1, and the support shaft 2 is fixed with a sleeve A gear ring 3 is provided, the top of the support shaft 2 extends through the top wall of the base 1 to the outside and is fixedly connected with a turntable 4, the turntable 4 is a cavity structure, the top side of the turntable 4 is symmetrically opened with an opening 5, and the inner wall of the turntable 4 is on both sides A horizontal rotating shaft 6 is rotated between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com