Water-based binder as well as preparation method and application thereof

A water-based binder and initiator technology, applied in the direction of binder types, nitrile copolymer binders, structural parts, etc., can solve the problems of oil-based binder pollution, affecting the efficiency of the coating process, etc., to improve efficiency , There is no environmental pollution problem, the effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

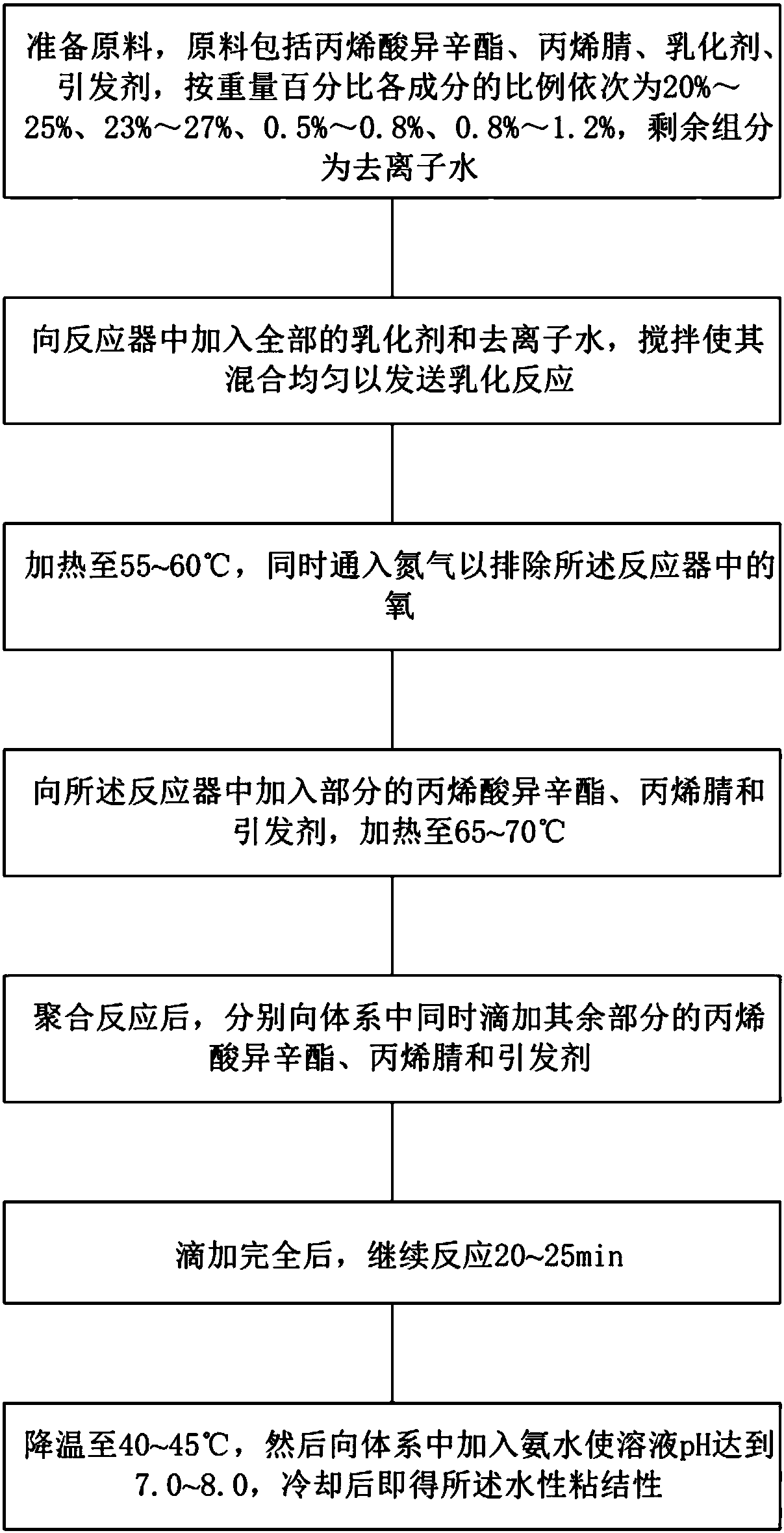

[0039] see figure 1 , the invention provides the preparation method of above-mentioned water-based binder, comprising:

[0040] Prepare each raw material according to the above-mentioned raw material types and ratios;

[0041] Add all the emulsifier and deionized water to the reactor, stir to make it evenly mixed to send the emulsification reaction;

[0042] Heating to 55-60°C while feeding nitrogen to eliminate oxygen in the reactor;

[0043] Add part of isooctyl acrylate, acrylonitrile and initiator into the reactor, and heat to 65-70°C;

[0044] After the polymerization reaction, add the rest of the isooctyl acrylate, acrylonitrile and initiator dropwise to the system simultaneously;

[0045] After the dropwise addition is complete, continue to react for 20-25 minutes;

[0046] The temperature is lowered to 40-45°C, and then ammonia water is added to the system to make the pH of the solution reach 7.0-8.0, and the water-based binder is obtained after cooling.

[0047] ...

Embodiment 1

[0056] A water-based binder, the raw materials of the water-based binder include isooctyl acrylate, acrylonitrile, an emulsifier, and an initiator, and the proportions of each component by weight percentage are 20%, 27%, 0.5%, and 0.9% , the remaining components are deionized water, the emulsifier is a mixed emulsification system of anionic emulsifier and nonionic emulsifier, the mass ratio of the anionic emulsifier and the nonionic emulsifier is 3.5:1, the trigger The agent is ammonium sulfate-sodium bisulfite redox initiator system.

[0057] The preparation method of the aqueous binder of the present embodiment:

[0058] Prepare each raw material according to the above-mentioned raw material types and ratios;

[0059] Add all the emulsifier and deionized water into the reactor, stir to make it evenly mixed to send the emulsification reaction, and the stirring time is 1h;

[0060] Heating to 55°C while feeding nitrogen to get rid of oxygen in the reactor;

[0061] Add part...

Embodiment 2

[0073] A water-based binder, the raw materials of the water-based binder include isooctyl acrylate, acrylonitrile, an emulsifier, and an initiator, and the proportions of each component by weight percentage are 25%, 25%, 0.6%, and 1.2% in sequence , the remaining components are deionized water, the emulsifier is a mixed emulsification system of anionic emulsifier and nonionic emulsifier, the mass ratio of the anionic emulsifier and the nonionic emulsifier is 4:1, the trigger The agent is ammonium sulfate-sodium bisulfite redox initiator system.

[0074] The preparation method of the aqueous binder of the present embodiment:

[0075] Prepare each raw material according to the above-mentioned raw material types and ratios;

[0076] Add all the emulsifier and deionized water into the reactor, stir to mix evenly to send the emulsification reaction, the stirring time is 1.3h;

[0077] Heating to 58° C. while feeding nitrogen to get rid of oxygen in the reactor;

[0078] Add part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap