Deformable kitchen ventilator

A range hood and oil fume technology, applied in the field of deformable range hoods, can solve the problems of wasting gas, easy to touch heads, poor combination, etc., and achieve the effects of improving practical effects, avoiding bumps, and improving smoking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

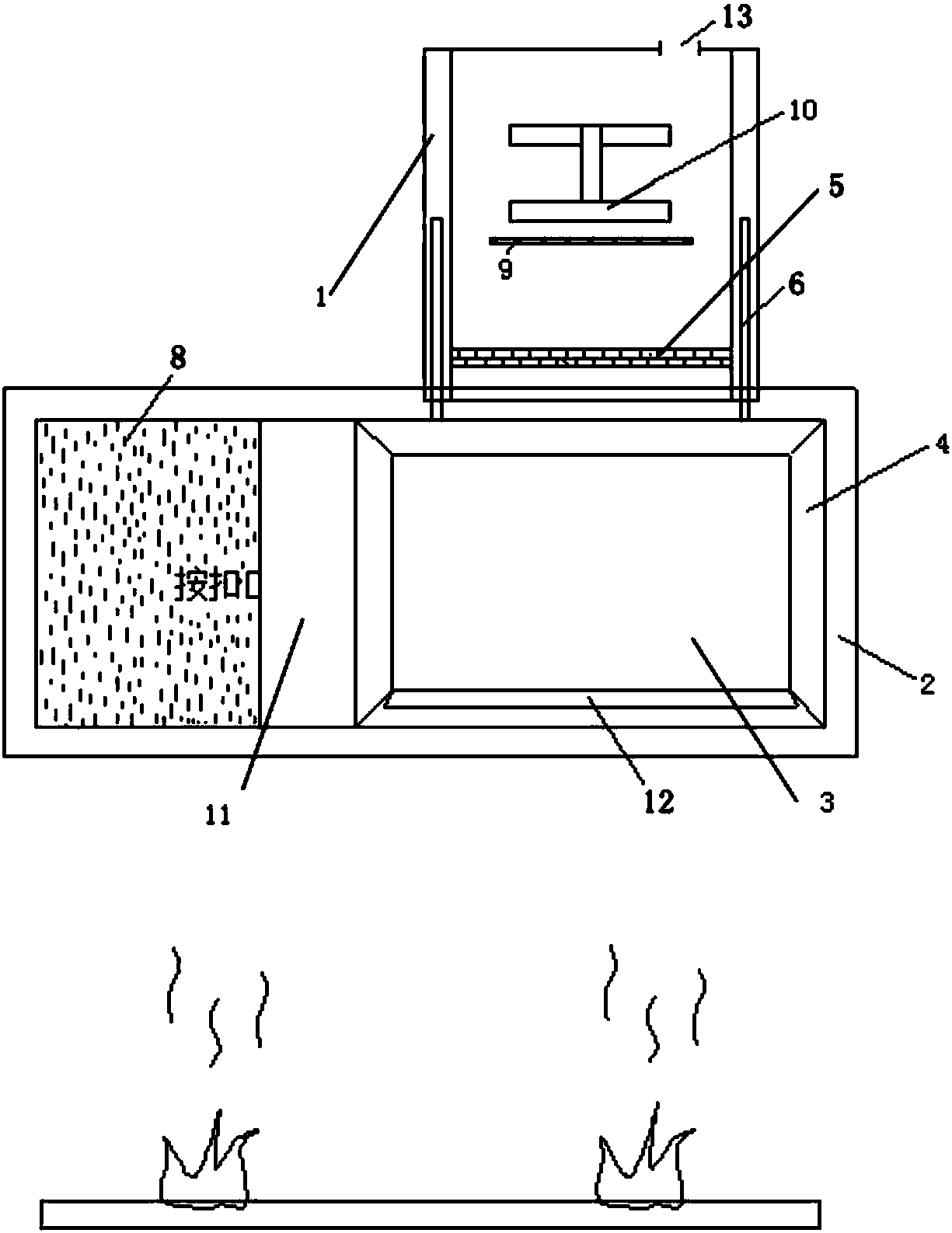

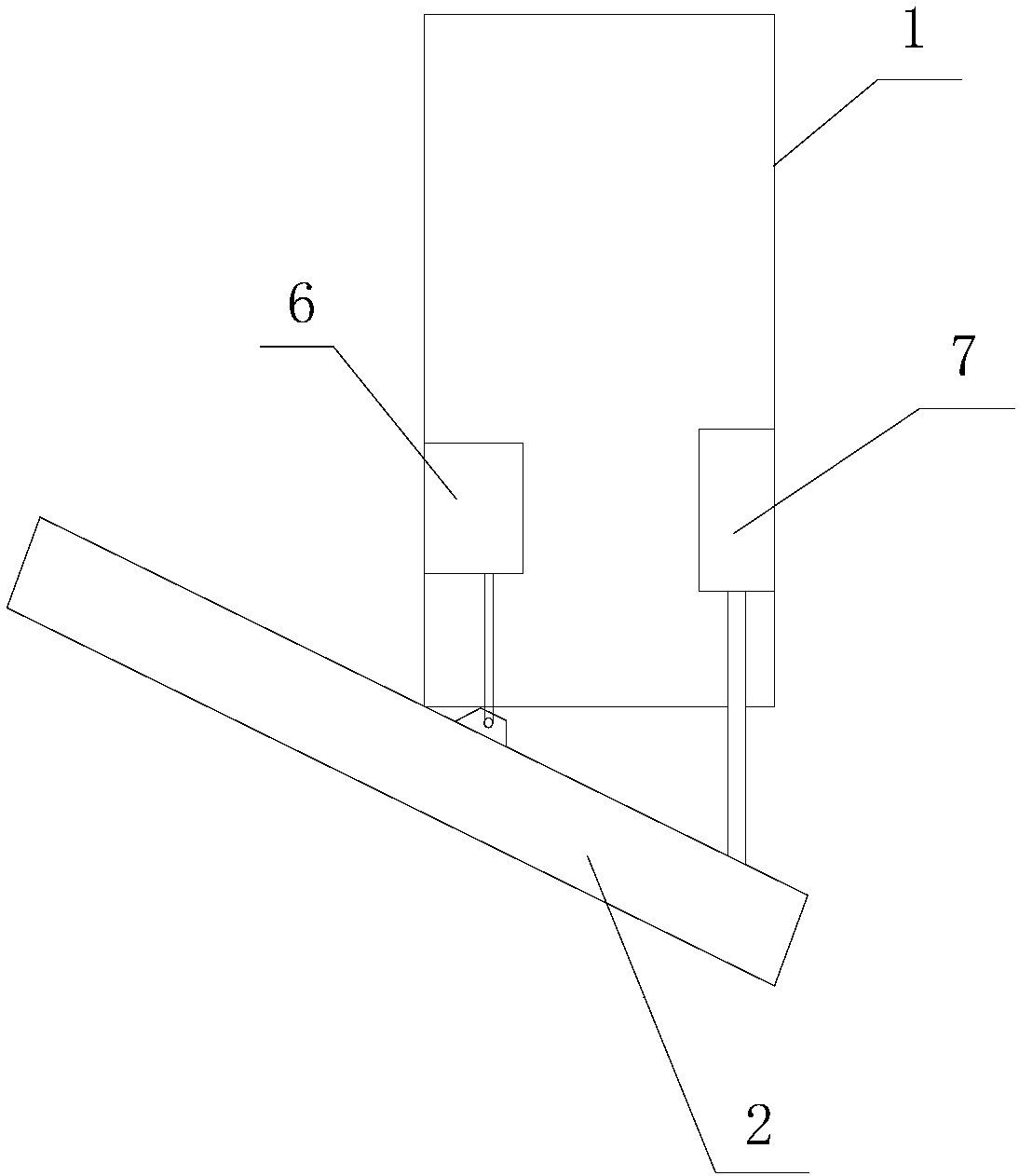

[0025] A deformable range hood is characterized in that it includes a smoke collection hood 2 arranged above the stove, a smoke exhaust part arranged on the top of the smoke collection hood 2, and is used to connect the smoke collection hood 2 and the smoke exhaust The connection part of the part and the control part for controlling the operation of the equipment;

[0026] A soot area and a steam area are arranged inside the fume collecting hood 2, and a heat insulation board 11 is arranged between the soot area and the steam area, and a steam inlet grid 8 is arranged on the top of the soot area, and the inside of the soot area A condensation plate 3 is provided, and a smoke guide plate 4 is provided on the side wall of the oil fume area, and a smoke exhaust passage communicated with the smoke exhaust part is between the smoke guide plate 4 and the condensation plate 3;

[0027] The smoke exhaust part includes a smoke exhaust housing 1 with a hollow structure, the smoke exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com