Ion Thruster Lifetime Evaluation Method Based on Gate Corrosion Morphology and Electron Reflow

An ion thruster and life evaluation technology, which is applied in the testing of instruments, machines/structural components, measuring devices, etc., can solve the problems of poor life prediction accuracy and long life evaluation test time of ion thrusters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Aiming at the deficiencies in the prior art, the present invention proposes a method for evaluating the life of an ion thruster based on gate corrosion morphology and electron backflow, including the following steps:

[0061] Step 1, data acquisition of gate corrosion morphology

[0062] First of all, the characteristic quantities representing the corrosion morphology of the ion thruster grid are collected, mainly "corrosion depth of the surface groove downstream of the acceleration grid" and "diameter of the acceleration grid hole". in:

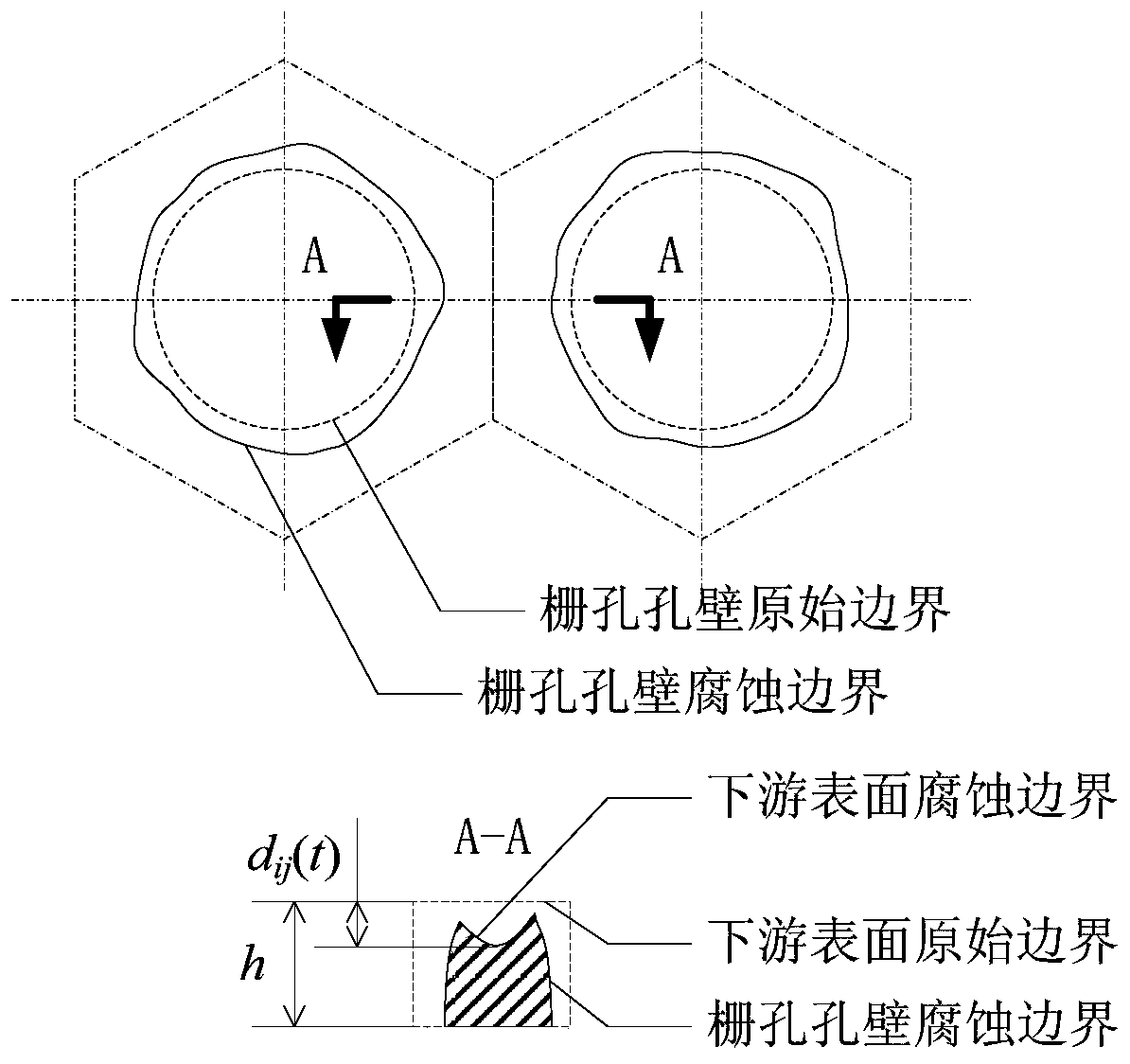

[0063] a) The groove corrosion depth on the downstream surface of the accelerating grid is based on the maximum value of the average groove corrosion depth of the three grid holes in the central area, that is in d ij (t) is the ith (i=1,2,...,nd, n d ≥3) grid hole and the groove corrosion depth of the surrounding jth (j=1,2,...,6) adjacent grid hole (such as figure 1 shown);

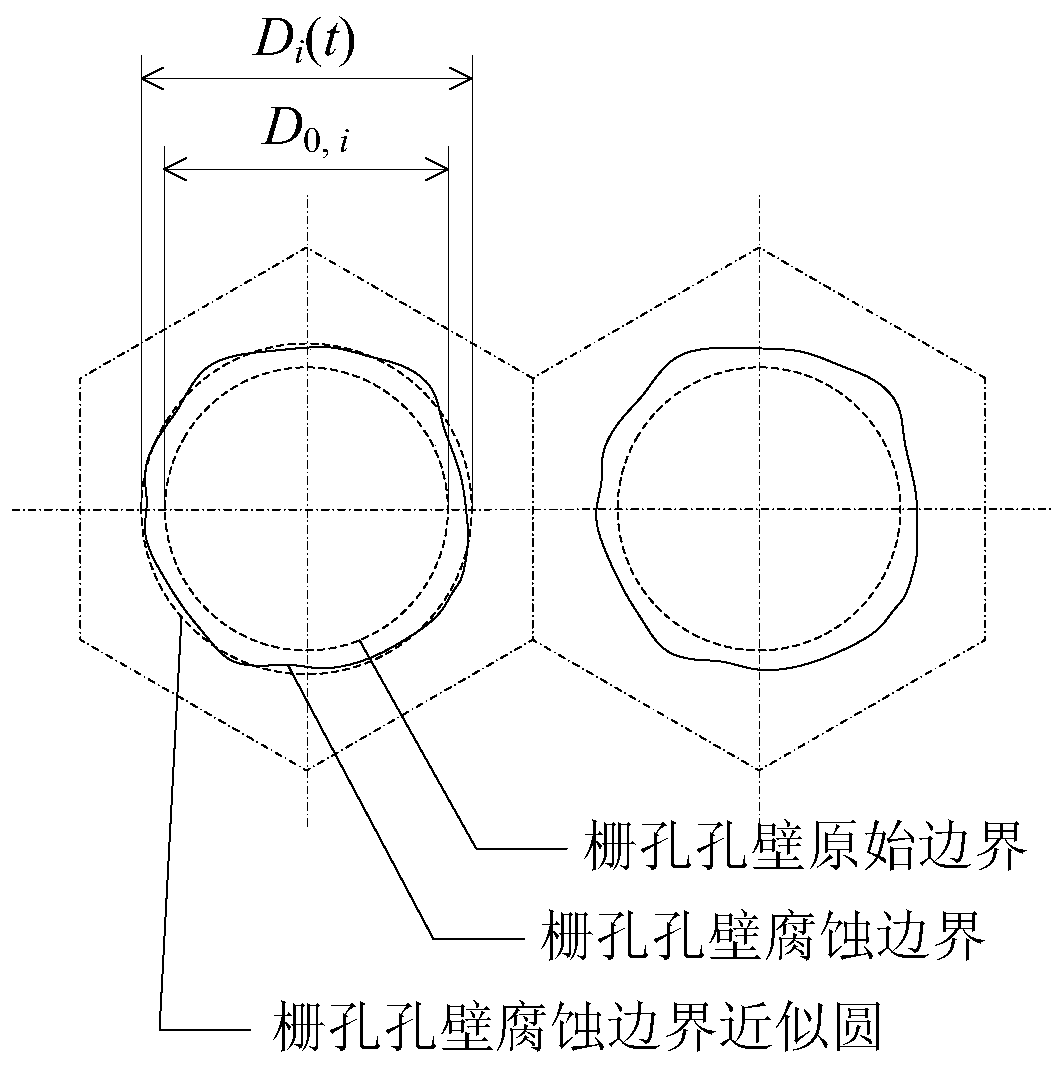

[0064] b) The diameter of the acceleration grid ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com