Process box jamming device

A processing box and paper clamping technology, applied in the field of processing boxes, can solve the problems of inconvenient operation, inability to detect the installation of anti-pollution paper, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments are described below with reference to the drawings.

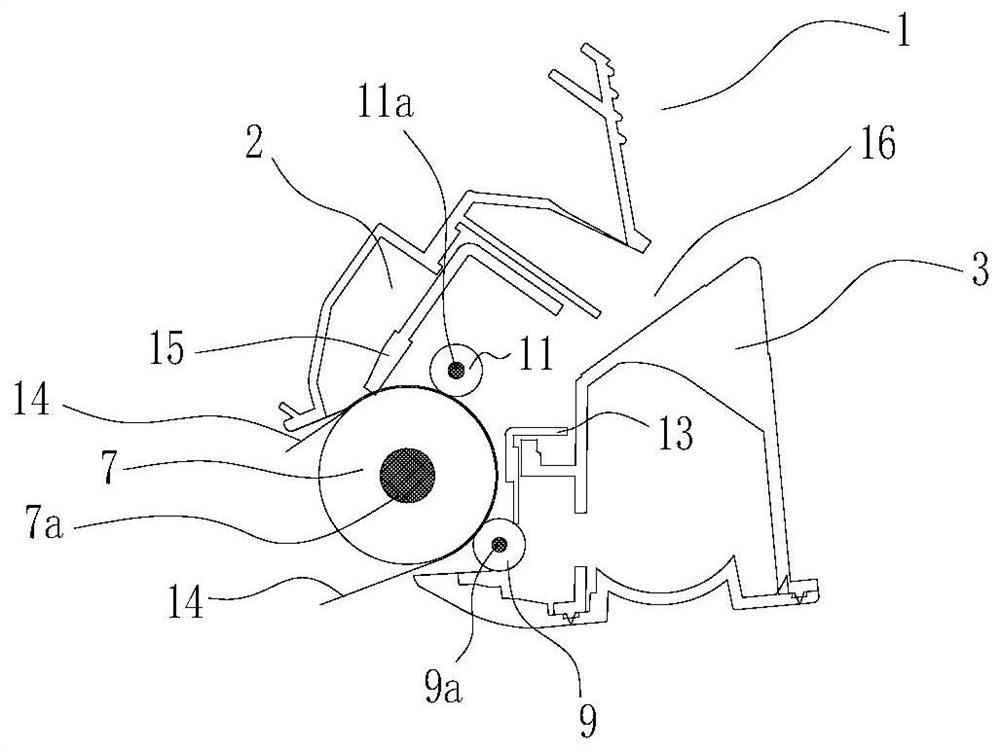

[0018] Such as figure 1 As shown, the process box 1 includes a waste toner bin 2 and a powder bin 3; the waste toner bin 2 is provided with a photosensitive drum 7, a charging roller 11 and a cleaning blade 15; the powder bin 3 is provided with a developing roller 9 and a powder outlet knife 13 The waste toner bin 2 is connected to the powder bin 3, and a laser port 16 is set between the waste toner bin 2 and the powder bin 3. The photosensitive drum 7, the developing roller 9 and the charging roller 11 are respectively provided with a photosensitive drum steel shaft 7a, a developing roller steel shaft 9a and a charging roller steel shaft 11a. The steel shaft 7a of the photosensitive drum, the steel shaft 9a of the developing roller and the steel shaft 11a of the charging roller can be respectively connected with the power supply unit on the image forming device and transmit voltage.

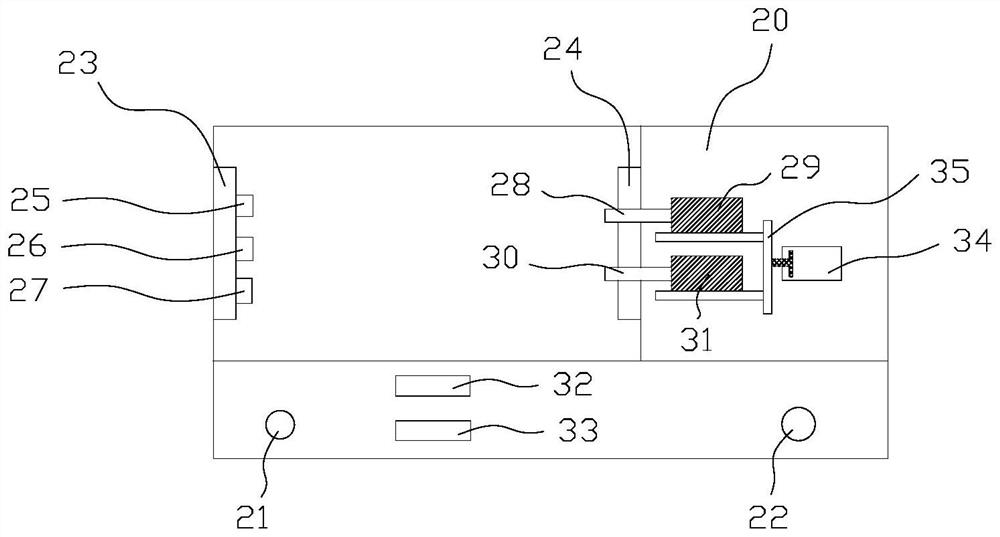

[0019] Such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com