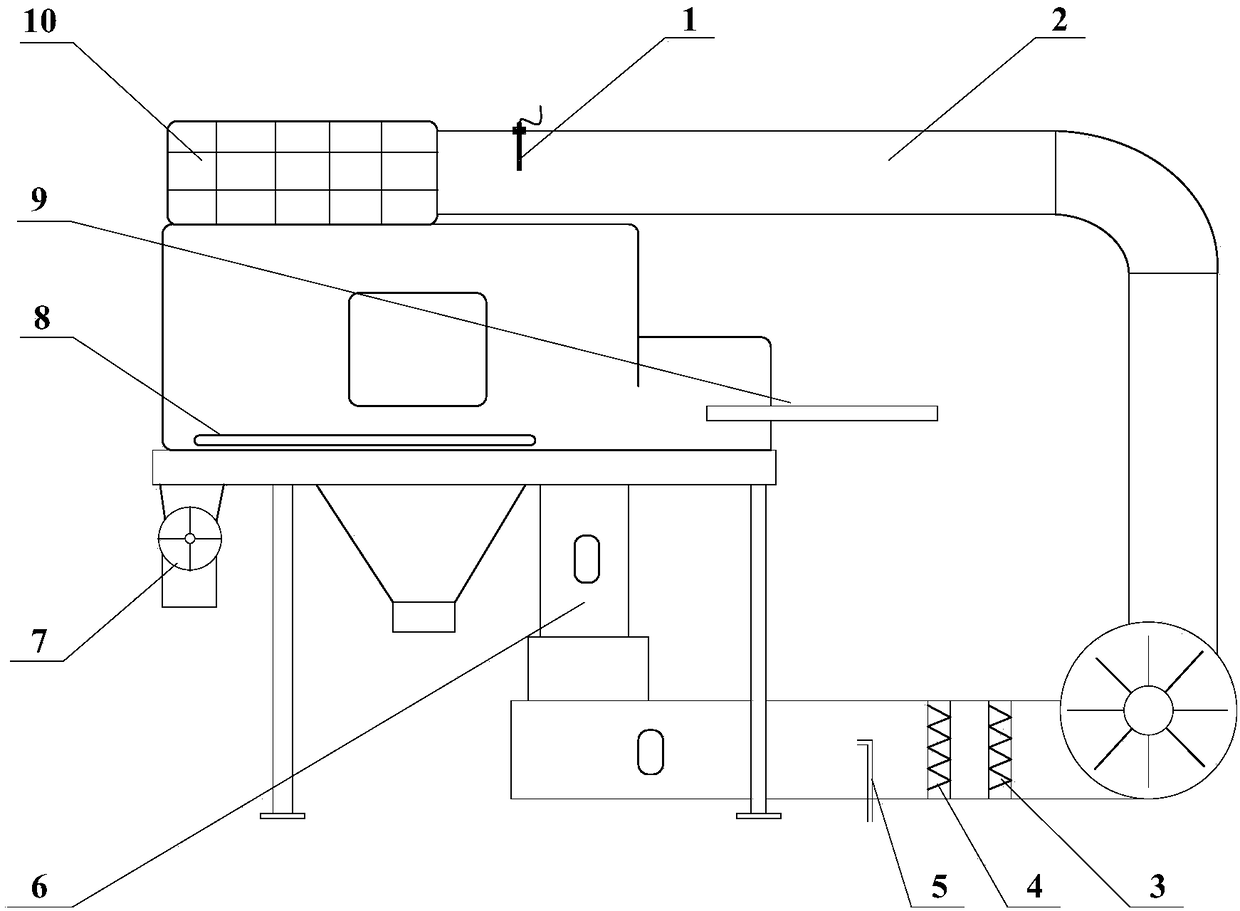

Circulating air temperature and humidity regulation and control system for tobacco shred on-site winnowing machine and control method thereof

A control system, a technology of circulating air, applied in electrical program control, chemical instruments and methods, program control in sequence/logic controllers, etc., to reduce the loss of leaf silk, reduce energy consumption, and improve sweetness and comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

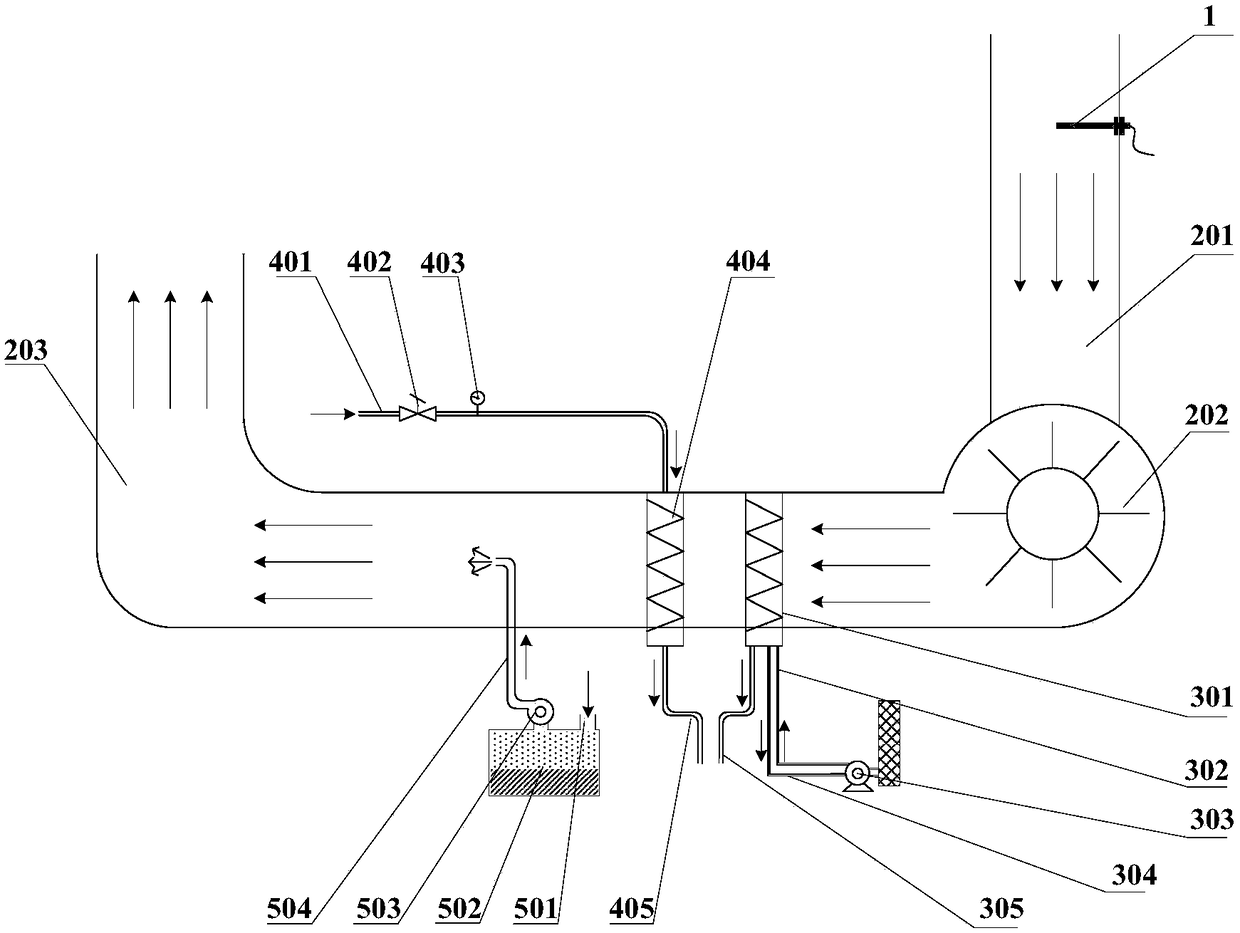

Method used

Image

Examples

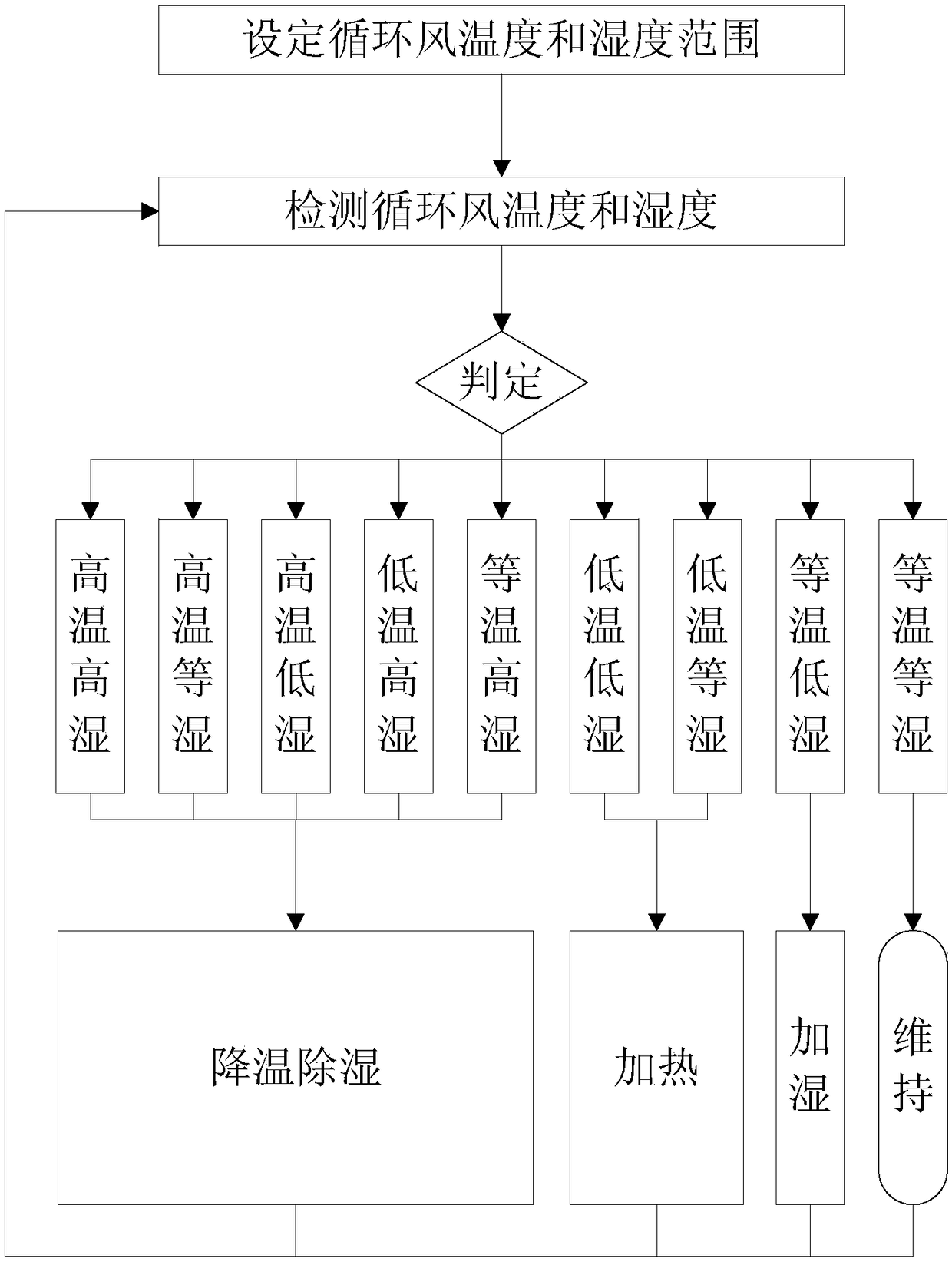

Embodiment 1

[0046] Example 1, high temperature and high humidity, that is, the temperature and absolute humidity of the circulating air are higher than the upper limit of the set value, the cooling and dehumidification device is preferentially turned on, and the frequency conversion compressor 303 is adjusted according to the difference between the actual value of the temperature and humidity of the circulating air and the set value For power, first realize low temperature and equal humidity, and then adjust according to the corresponding situation in Example 7. For example, the actual temperature of the circulating air is 35.00°C, the relative humidity is 80.00%, and the absolute humidity is 31.66g / m 3 , first cool down and dehumidify to a temperature of 18.81°C, a relative humidity of 100%, and an absolute humidity of 16.12g / m 3 , and then turn on the heating device to a temperature of 25.00°C, a relative humidity of 70.00%, and an absolute humidity of 16.12g / m 3 .

Embodiment 2

[0047] Example 2, high temperature and equal humidity, that is, the temperature of the circulating air is higher than the upper limit of the set value and the absolute humidity is within the range of the set value, the cooling and dehumidification device is turned on first, and adjusted according to the difference between the actual value of the temperature and humidity of the circulating air and the set value The power of the frequency conversion compressor 303 first realizes low temperature and equal humidity, and then adjusts it according to the corresponding situation in Embodiment 7. For example, the actual temperature of the circulating air is 35.00°C, the relative humidity is 40.75%, and the absolute humidity is 16.12g / m 3 , cooling and dehumidification to a temperature of 25.00°C, a relative humidity of 70.00%, and an absolute humidity of 16.12g / m 3 .

Embodiment 3

[0048] Example 3, high temperature and low humidity, that is, the temperature of the circulating air is higher than the upper limit of the set value and the absolute humidity is lower than the lower limit of the set value, the cooling and dehumidification device is turned on first, and the frequency conversion compression is adjusted according to the difference between the actual value of the circulating air temperature and the set value The power of the machine 303 first realizes isothermal and low humidity, and then adjusts according to the corresponding situation in Embodiment 8. For example, the actual temperature of the circulating air is 35.00°C, the relative humidity is 25.00%, and the absolute humidity is 9.89g / m 3 , first cool down and dehumidify to a temperature of 25.00°C, a relative humidity of 42.94%, and an absolute humidity of 9.89g / m 3 , and then turn on the humidifier until the temperature is 25.00°C, the relative humidity is 70.00%, and the absolute humidity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com