Plastic furniture cabinet

A furniture cabinet and plastic technology, applied in the field of furniture cabinets, can solve the problems of being easily deformed by moisture, not easy to carry, and short life, and achieve the effects of long life, light weight, and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

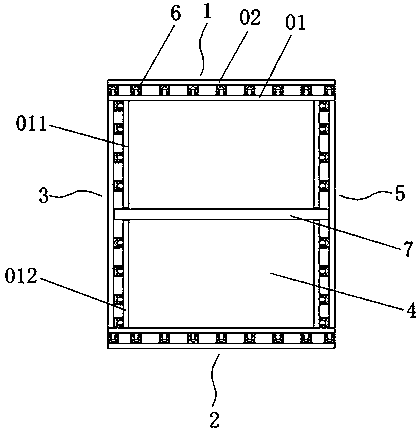

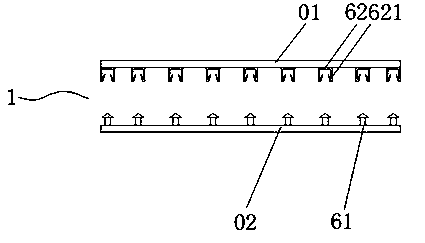

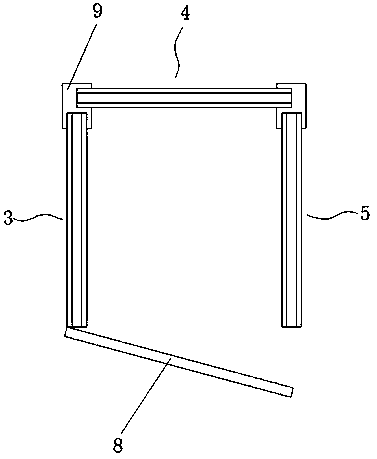

[0015] The specific embodiment of a kind of plastic furniture cabinet of the present invention, as Figure 1 to Figure 4 As shown, the plastic furniture cabinet includes a cabinet body and a cabinet door 8 hinged on the cabinet body. And the right side plate 5, the top plate 1, the bottom plate 2, the left side plate 3, the back plate 4 and the right side plate 5 are all formed by fastening the inner layer plate 01 and the outer layer plate 02 through the male and female buckle structure 6. In this embodiment Among them, the male and female buckle structure 6 includes an arrow-shaped protrusion 61 arranged on the inner board 01 and a U-shaped clip 62 arranged on the outer board 02, and the opening of the U-shaped clip 62 is provided with an inward bending The bent part 621 of the bent part 621 forms a barb structure to prevent the male and female buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com