Solution dedusting device

A dust removal device and solution technology, applied in cleaning methods and utensils, electrostatic cleaning, chemical instruments and methods, etc., can solve problems such as inconvenient operation, troublesome static electricity and dust removal, dust falling back to the surface of objects, etc. Simple, no-tip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

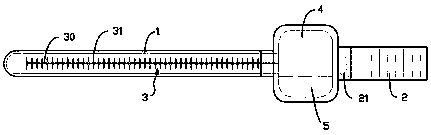

[0014] exist figure 1 In the shown embodiment one, the solution dedusting device includes a hollow rod 1 and a handle 2; the hollow rod 1 is made of an insulator, and a charging shaft 3 is arranged inside it along the axis, and the charging shaft 3 includes a 1 shaft tube 30 extending along the axis, and conical tube groups equidistantly distributed on the shaft tube 30; the tapered tube group includes conical tubes 31 uniformly distributed around the axis of the hollow rod 1 and tapered at the outer end A solution cavity 4 storing a conductive solution 5 is provided between the hollow rod 1 and the handle 2; the conductive solution 5 can only flow in the tapered tube 31, the shaft tube 30, and the solution cavity 4, and The volume of the conductive solution 5 is greater than the total volume of the tapered tube 31 and the shaft tube 30, and smaller than the volume of the solution chamber 4, so that the conductive solution 5 can completely flow into the solution chamber 4, and...

Embodiment 2

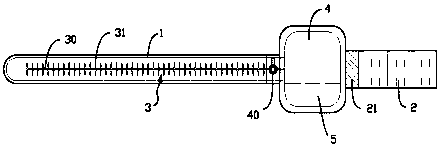

[0018] for figure 2 The second embodiment shown is different from the first embodiment in that a manual valve 40 is also provided between the solution chamber 4 and the shaft tube 30 so that the shaft tube 30 and the solution chamber 4 Stay connected or block. Thus, it can be ensured that the conductive solution 5 is completely kept in the solution chamber 4 when the dust removal device is not in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com