Rock block protection surface structure filled with degradable bagged materials

A surface structure and bagging technology, which is applied in coastline protection, water conservancy engineering, sea area engineering, etc., can solve the problems of poor water permeability and poor adaptability to deformation, so as to improve the compactness, increase the adaptability to deformation, and increase the opening rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

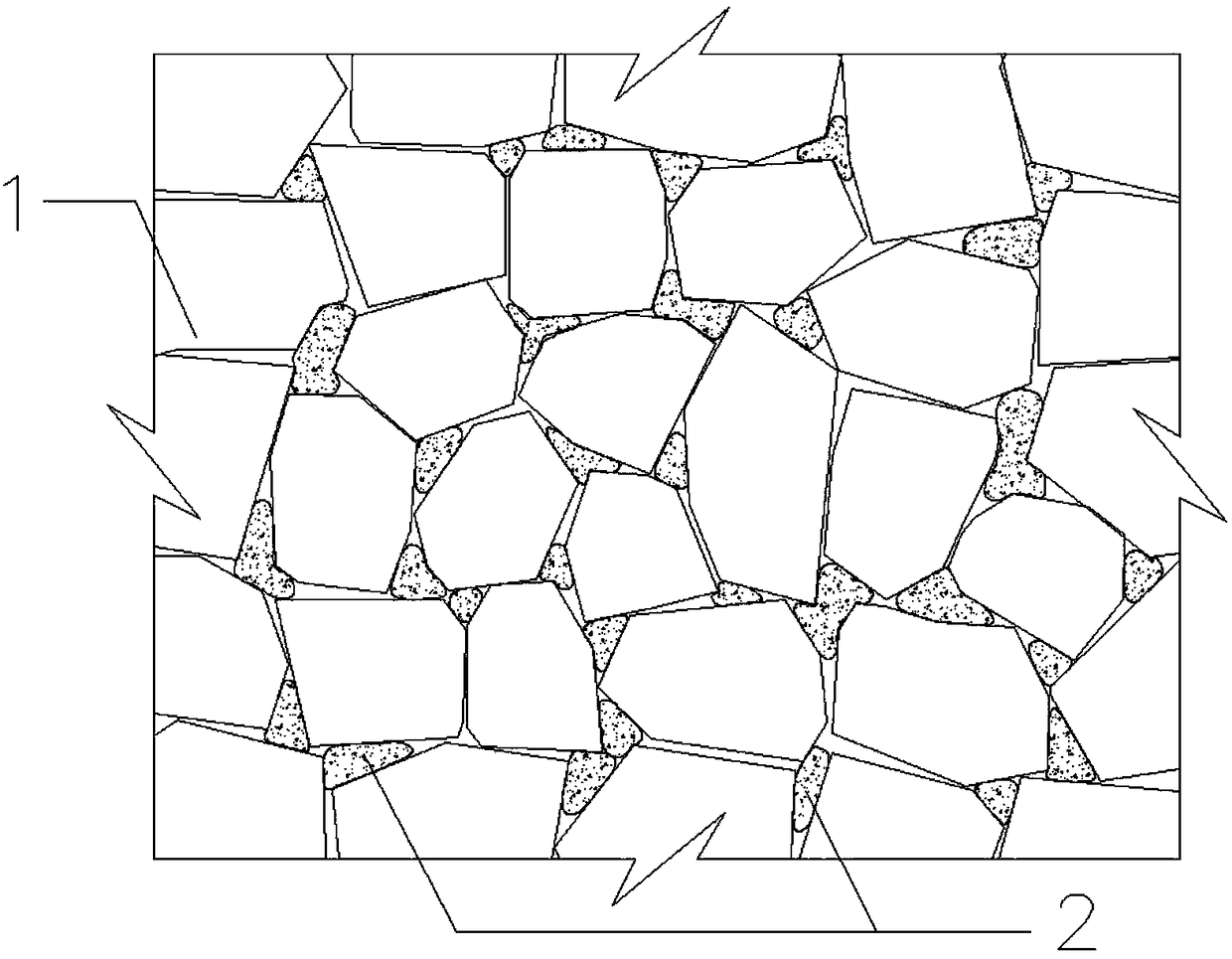

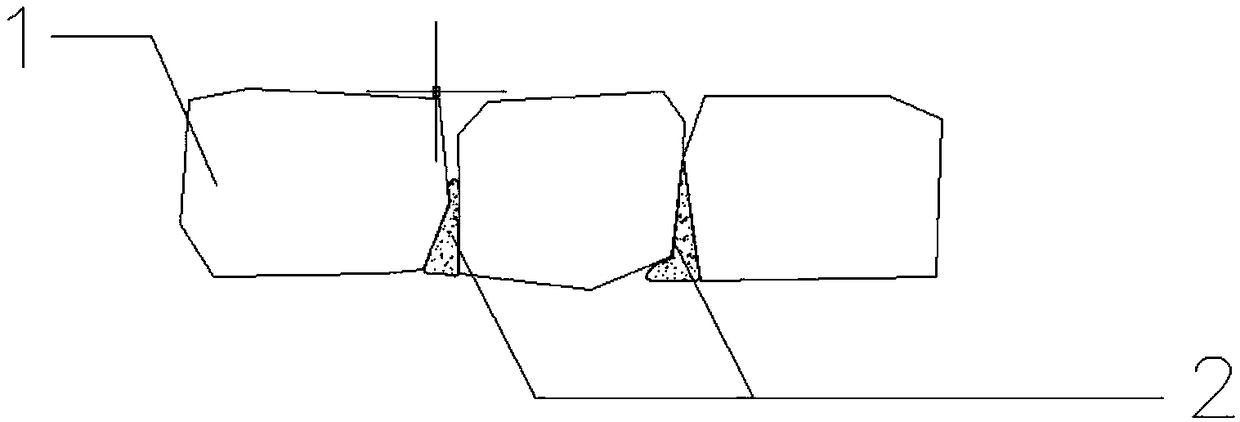

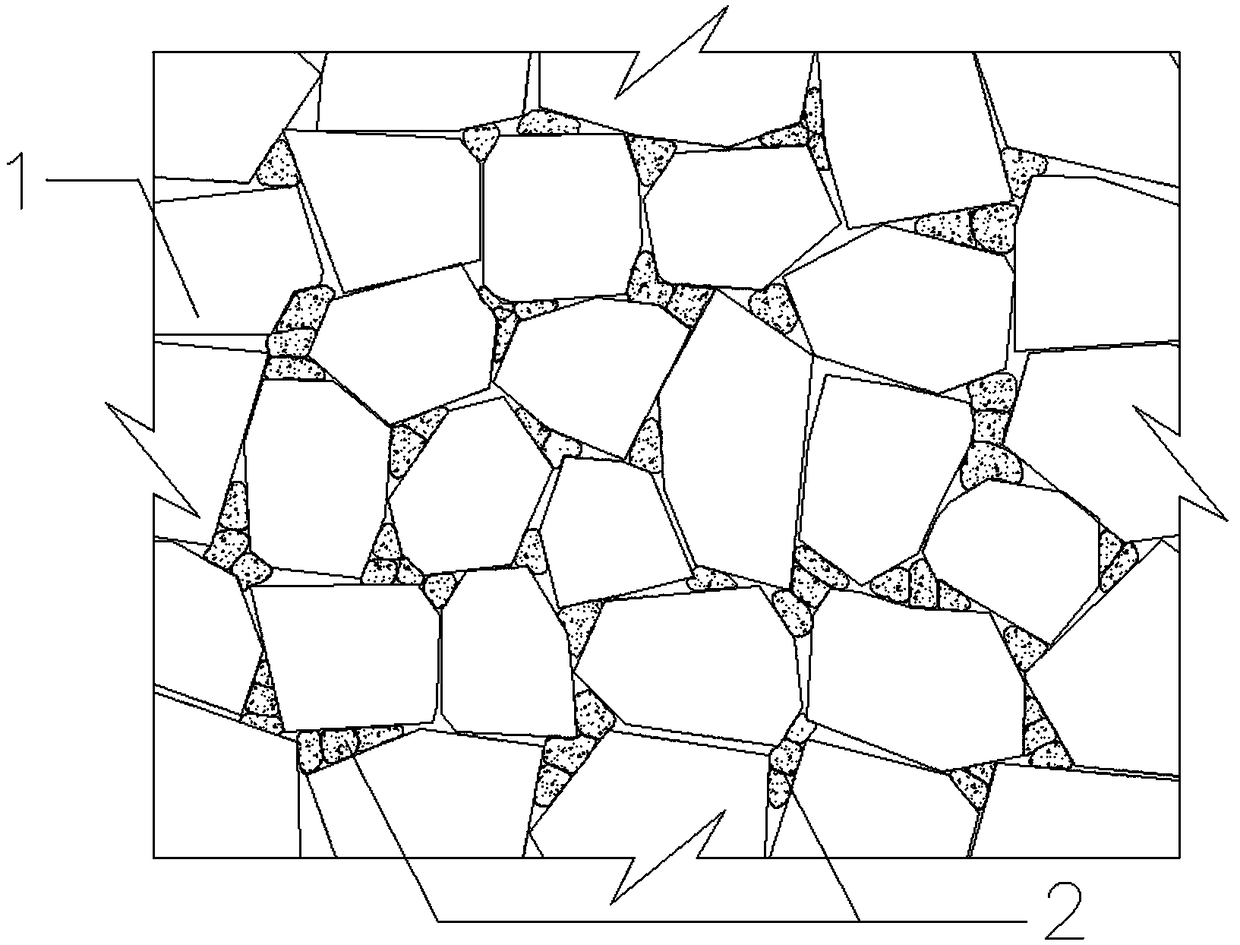

[0034] refer to Figure 1 to Figure 13 , a block stone protection structure filled with degradable bagged materials, including block stones 1, each block stone 1 is built close to the masonry to form a block stone protection surface, and the gaps or triangular joints around the block stones 1 are filled The degradable bag filling material 2 is used to connect two adjacent stone blocks through the degradable bag filling material 2 .

[0035] Further, the gaps or triangular gaps around the block 1 are filled with degradable bags 2 . It can be one bag, or two bags or even more bags.

[0036] Preferably, the degradable bag filling material 2 is cementitious material filled with degradable bags.

[0037] The cementing material refers to a mixture made of cementing materials and aggregates.

[0038] The cementing material is cement, cement-based grouting material or epox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com