Traction chain of slag conveyor

A slag scraper and chain technology, which is applied in the direction of drag chains, hanging chains, chain links, etc., can solve the problems of chain wear, spillage, bucket tilting, etc., and achieve the effect of prolonging the service life and preventing materials from spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

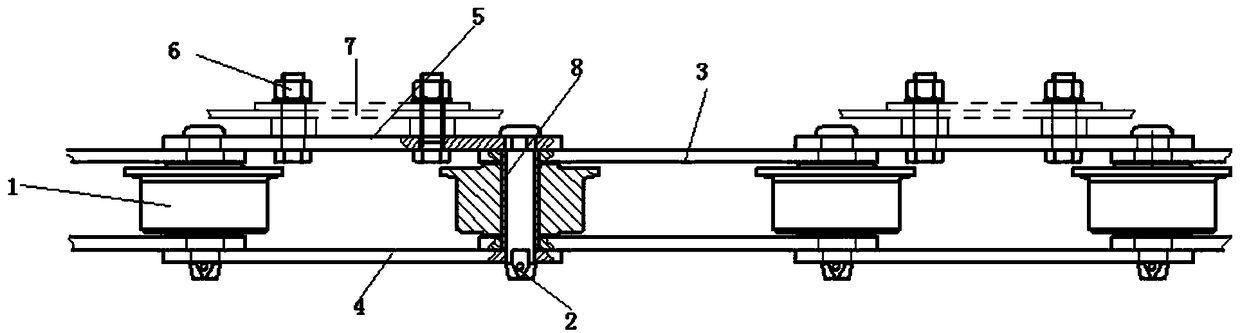

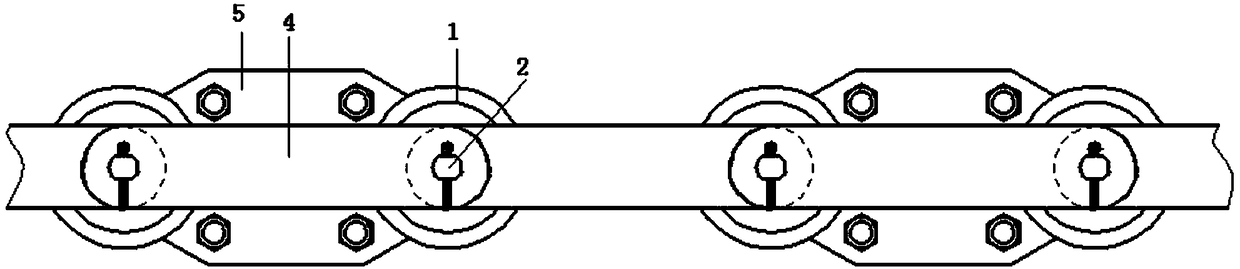

[0018] A slag fishing machine traction chain, such as figure 1 and figure 2 As shown in the figure, it includes a number of chain links that are connected and fixed in sequence. Each chain link includes two rollers 1. A fixing through hole is opened at the center of the surface of the two rollers 1, and a pin shaft 2 is installed in the fixing through hole. Two inner link plates 3 are sleeved and fixed between the pins 2 of the roller 1, the two rollers 1 are connected by the two inner link plates 3, and the two inner link plates 3 are located at the upper and lower ends of the roller 1 respectively. At the same time, one end face of the two inner link plates 3 is pressed and connected with the upper and lower end faces of the roller 1 respectively;

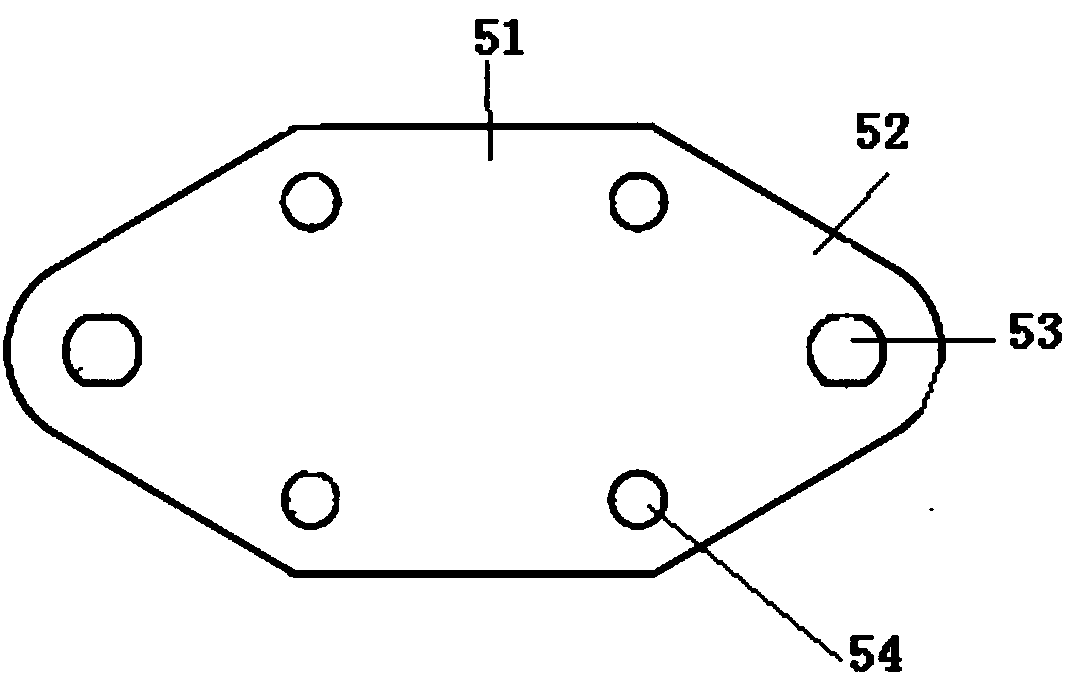

[0019] The two adjacent chain links are connected by the first outer link plate 4 and the second outer link plate 5, and the first outer link plate 4 and the second outer link plate 5 are respectively sleeved and fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com