Measuring device and measuring method used in installation process of gate groove

A technology for measuring devices and installation processes, applied in measuring devices, measuring instruments, surveying and navigation, etc., can solve problems such as difficulty in implementation, easy interference of line hammers, and errors in measurement results, so as to achieve accurate measurement and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

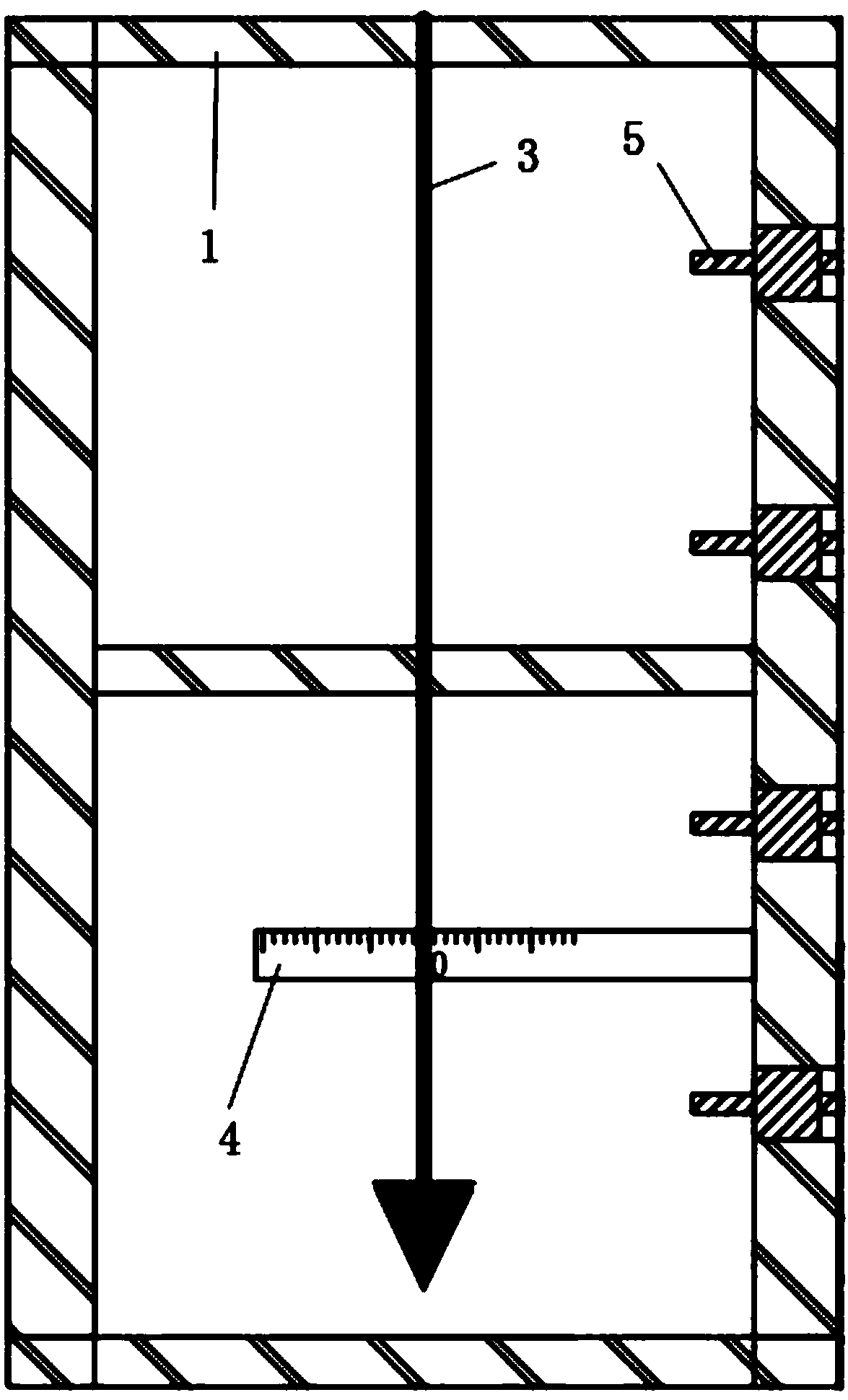

[0038] Such as Figure 1-3 , a measuring device used in the installation process of a gate slot, comprising:

[0039] Longitudinal beam 1 (longitudinal beam 1 is not the position marked 1 in the figure, but refers to the entire frame structure), the outer surface of said longitudinal beam 1 is provided with a side vertical surface for contacting with door slot 6 (vertical surface refers to the A straight line or a plane perpendicular to the plane, and the side vertical plane is a vertical plane among several outer surfaces arranged outside the stringer 1. At the same time, as far as the actual situation is concerned, there is no theoretical vertical plane. Here, " "Vertical surface" to represent this surface, and there is also a willingness to refer to the very high flatness of this surface, which is a surface processed with very high precision);

[0040] Vertical correction device, the vertical correction device is arranged inside the longitudinal beam 1 and can measure the ...

Embodiment 2

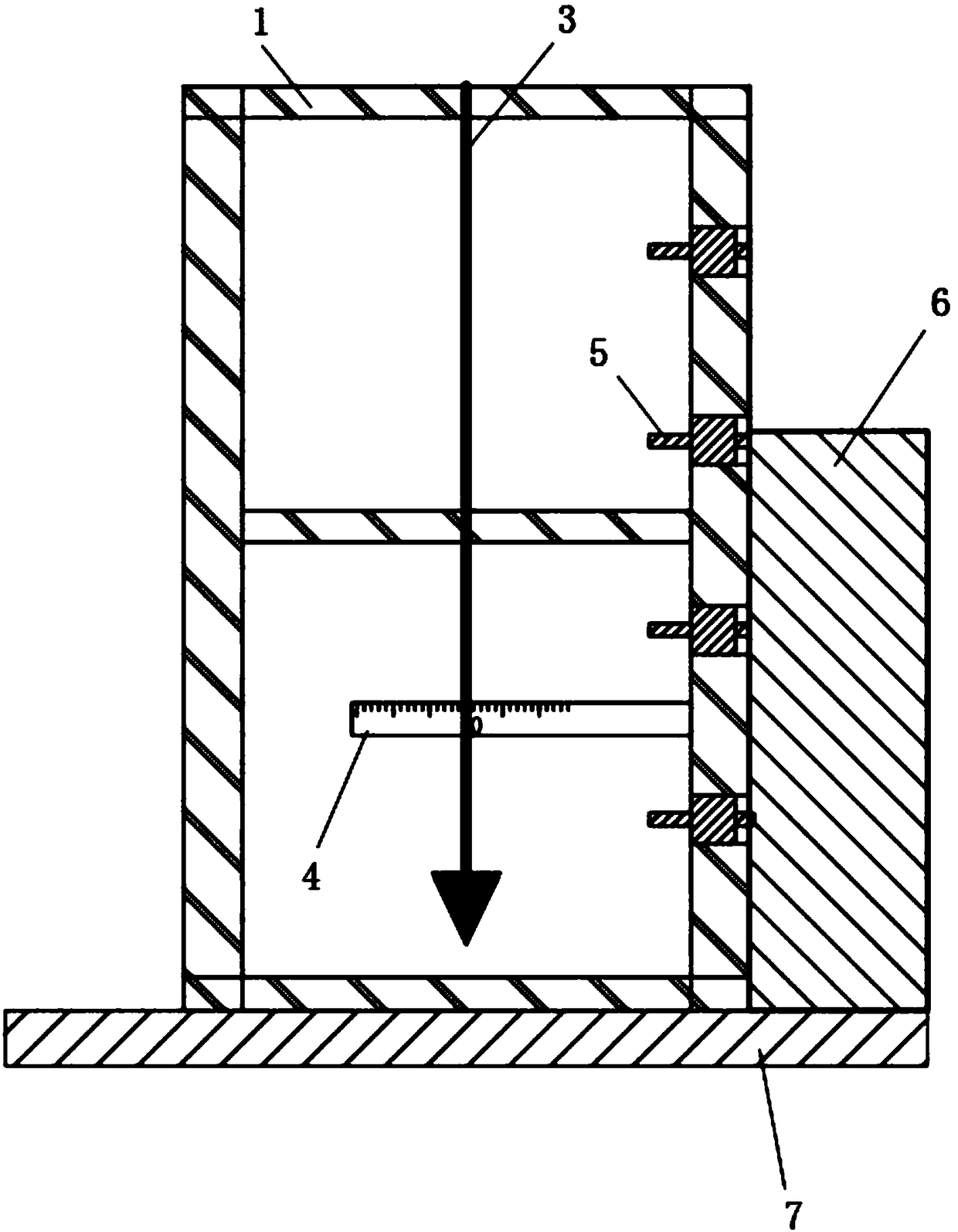

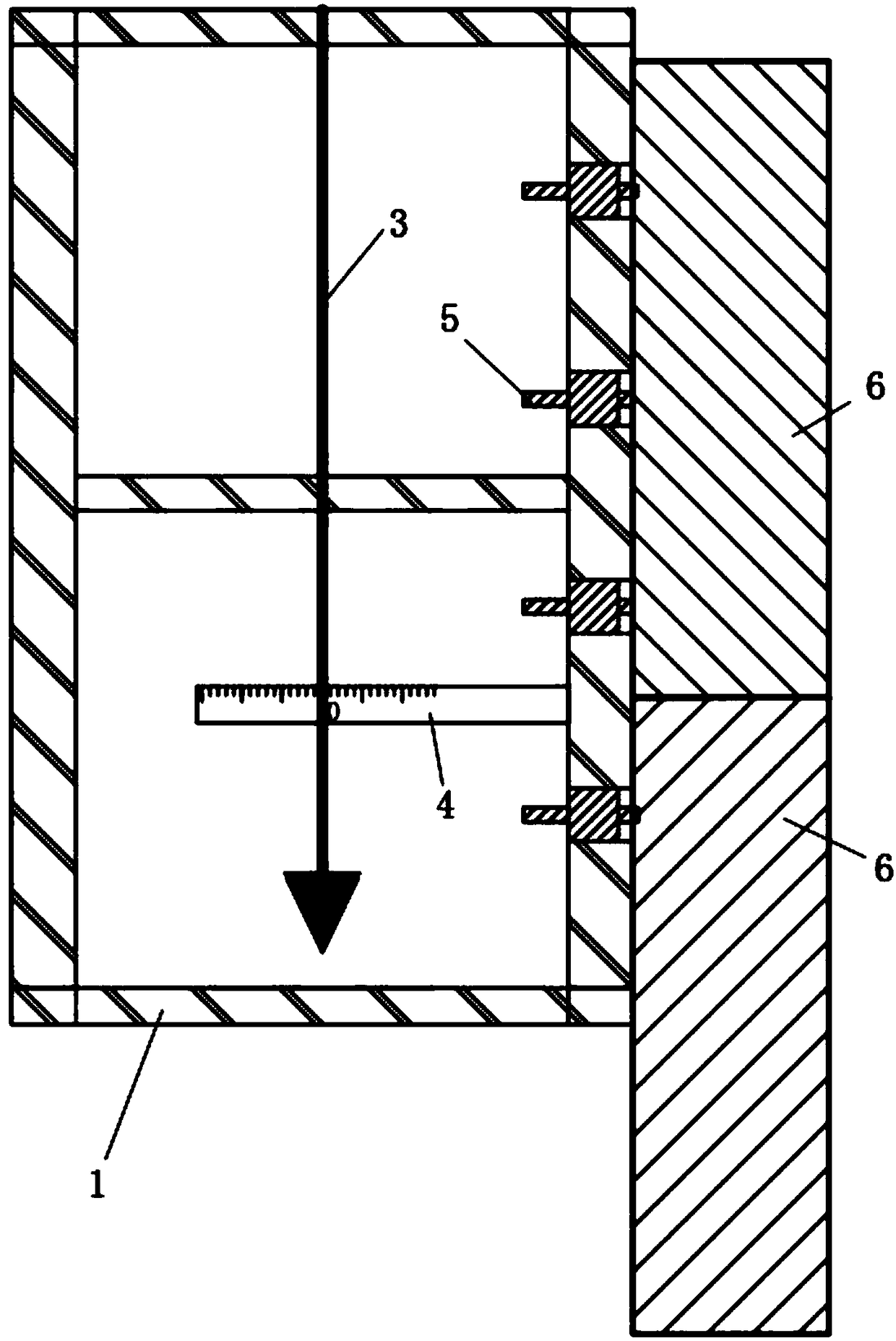

[0050] Such as Figure 4 , 5 , The difference between this embodiment and Embodiment 1 is that the number of said side vertical surfaces is two, which are relatively arranged on both sides of the longitudinal beam 1, and four distance measuring devices 5 are respectively arranged on both sides of the longitudinal beam 1 , which are arranged at equal intervals along the side vertical surface of the longitudinal beam 1. In this embodiment, the vertical correction device can be a fixed line hammer 3 or a laser plumb instrument 2, while Figure 4 , 5 It shows the inclination state of the door slot and the measuring device. The inclination angle is a bit exaggerated. When showing the inclination, the correspondence of the vertical correction device on the scale 4 is no longer "0" and the value can be read out for calculation. inclination.

Embodiment 3

[0052] Such as Image 6 The difference between this embodiment and Embodiment 1 is that the vertical correction device described in step B is a laser plumb meter 2, and a scale matching the laser plumb meter 2 is fixedly arranged in the longitudinal beam 1 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com