Thawing device for food detection and thawing method

A food detection and food technology, which is applied in the field of thawing devices for food detection, can solve the problems of slow thawing speed, inconvenient detection, poor thawing effect, etc., and achieve the effect of fast thawing speed, good thawing effect, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

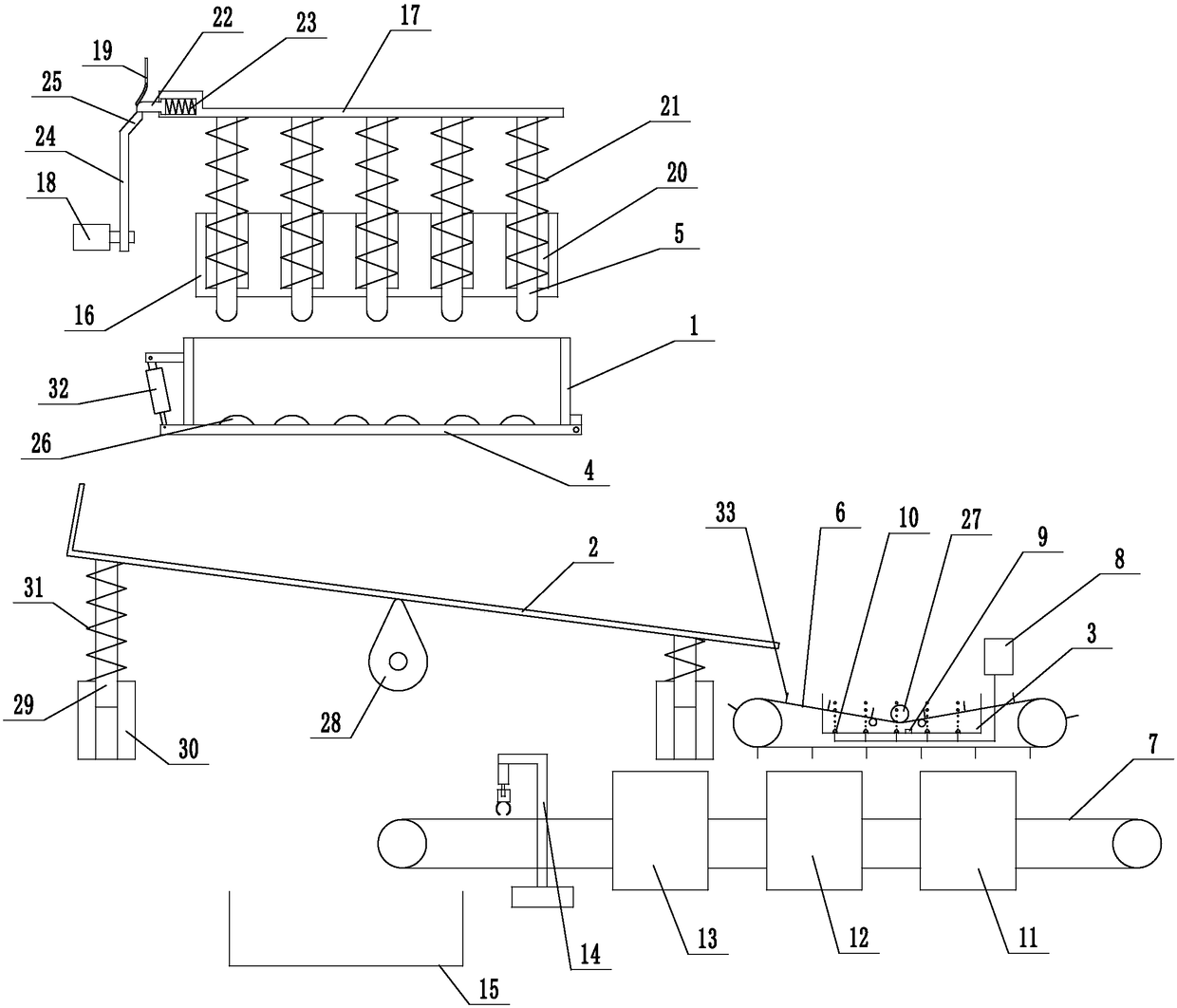

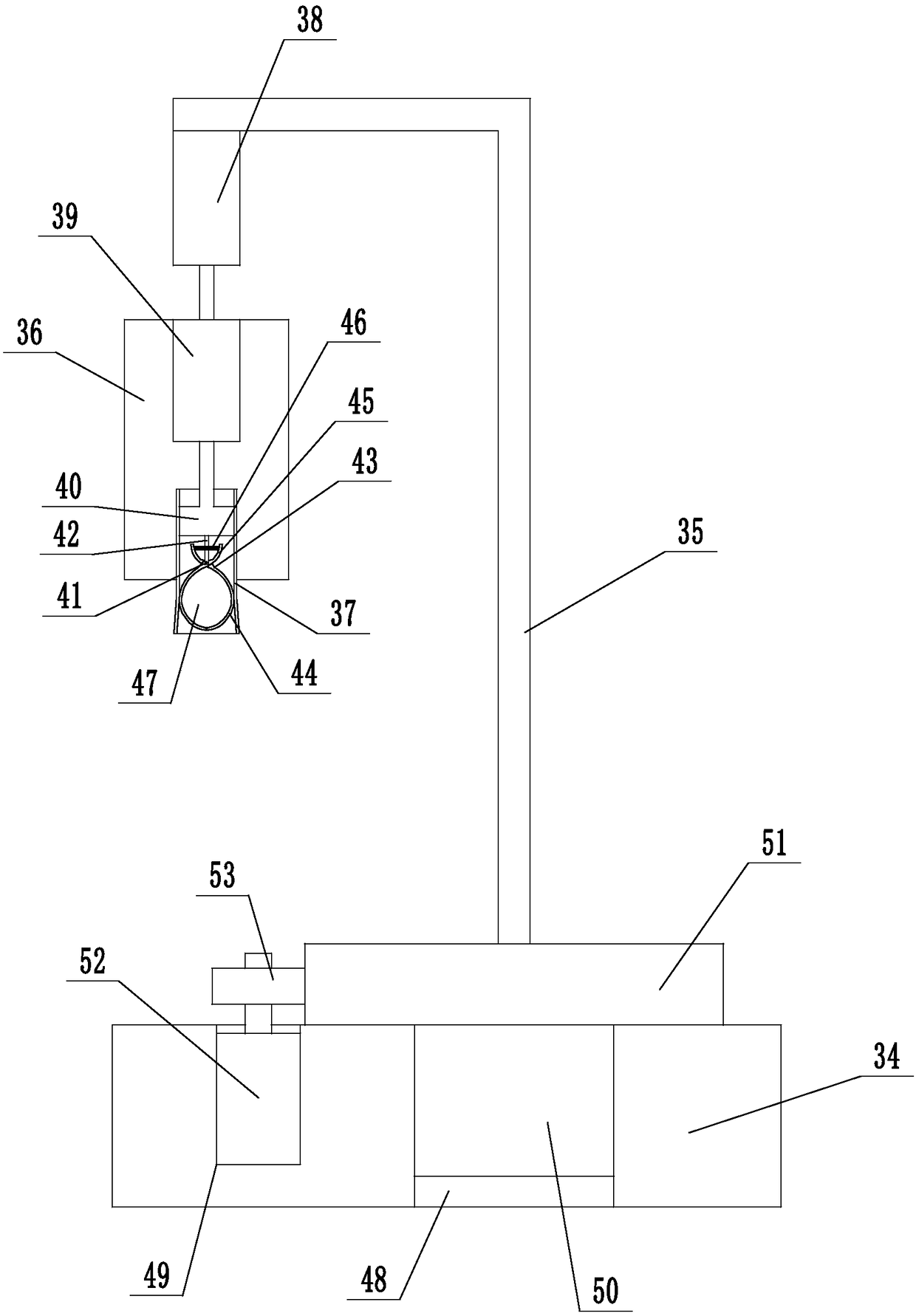

[0026] Embodiment: a kind of thawing device for food detection (see attached figure 1 , attached figure 2 ), including crushed ice tank 1, shaker plate 2, thawing water tank 3, the lower end of the crushed ice tank is hinged with a discharge cover 4 that can be opened downwards, and the outer wall of the crushed ice tank is hinged with a push piston cylinder 32, which pushes the telescopic rod of the piston cylinder Connected to the edge of the discharge cover, an ejection ice-breaking mechanism is installed above the ice-breaking trough, and the ejection-breaking ice mechanism is provided with several ejection rods 5 arranged towards the discharge cover, and several protrusions 26 are arranged on the upper surface of the discharge cover. , the protrusion is in a convex arc-shaped structure. A number of sieve holes are densely covered on the shaker plate, and the shaker plate is installed obliquely under the discharge cover. A shaking mechanism is installed under the shaker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com