Steel wire straightener convenient to maintain

A straightening machine and straightening technology, applied in the field of steel wire straightening, can solve the problems of complex structure, high maintenance cost, straightening work is not integrated with cutting work, etc., and achieves convenient later maintenance, simple structure and accurate straightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

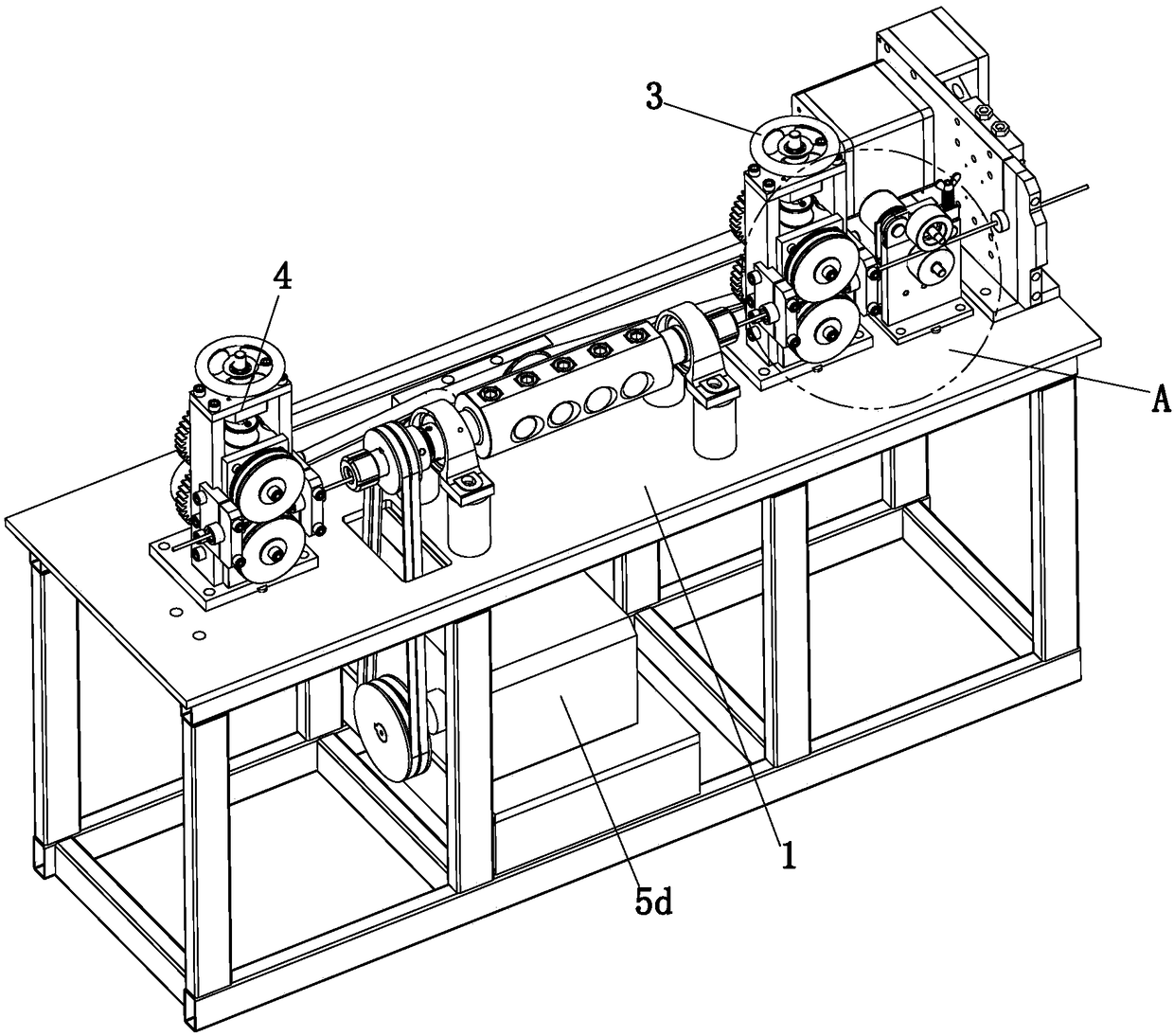

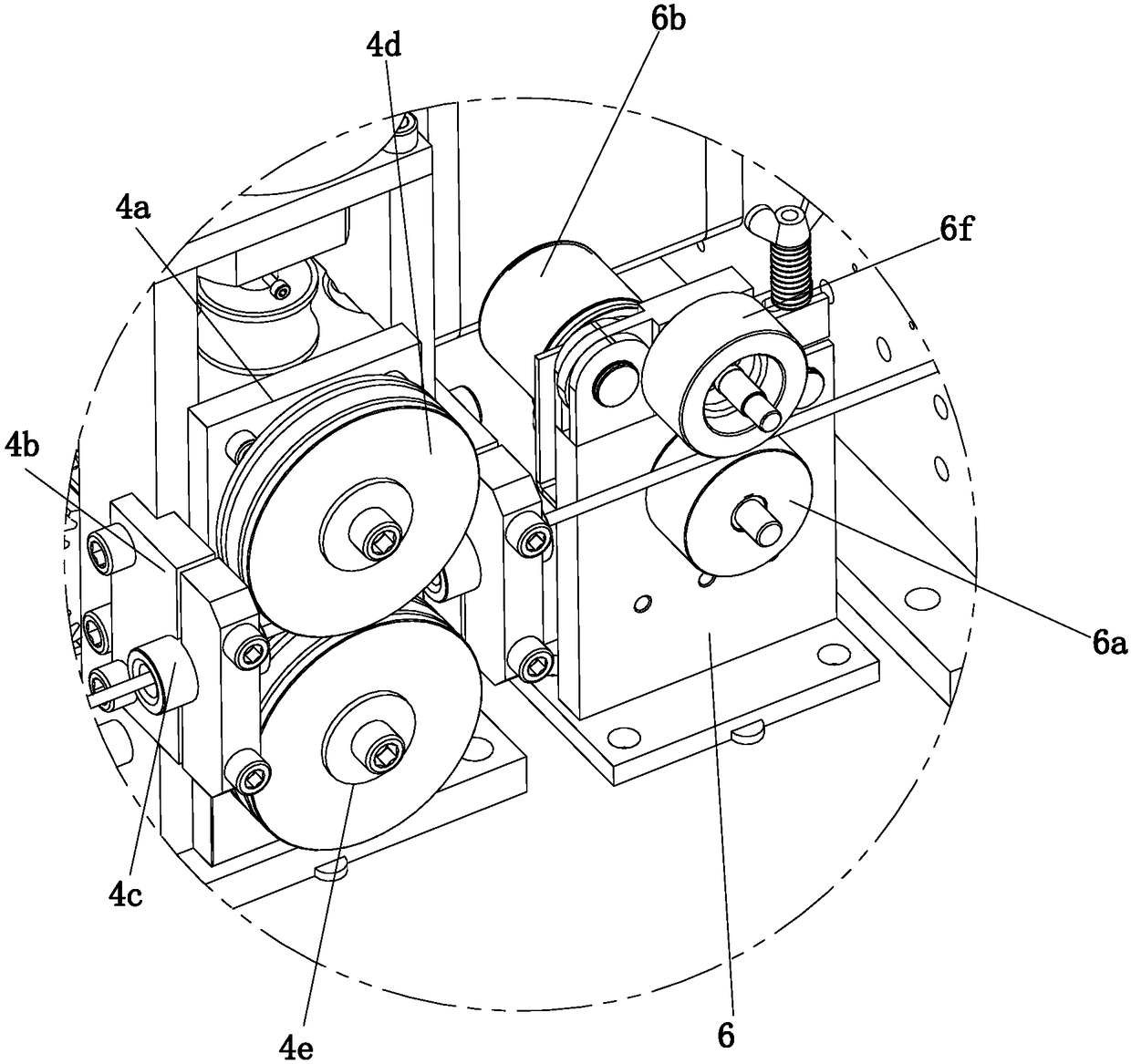

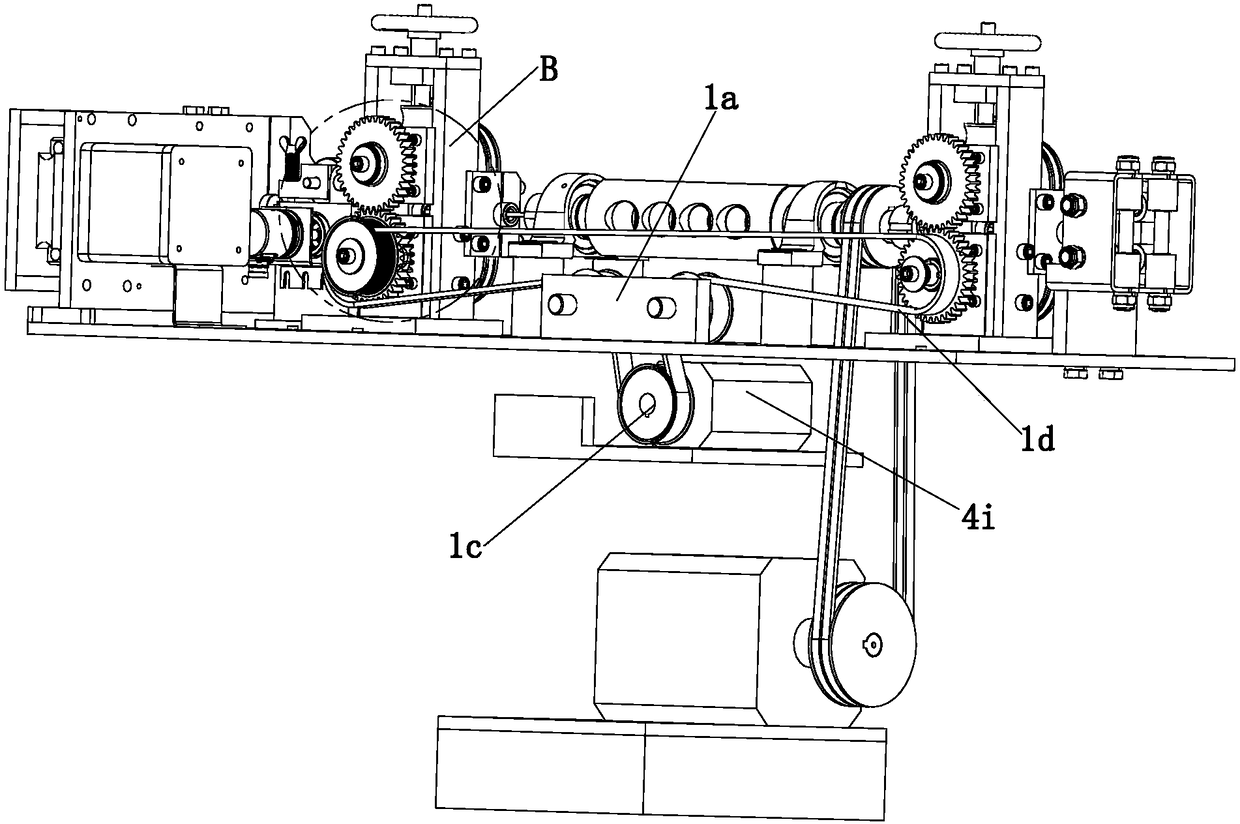

[0024] Reference Figure 1 to Figure 8 An easy-to-maintain steel wire straightening machine is shown, including a workbench 1 and a left-side straightening component 3 and a right-side straightening component 4 that are located on top of the worktable 1 and symmetrically arranged, and a left-side straightening component 3 and a right-side straightening component There is also a rotating cylinder 5a with a hollow structure between the straightening components 4, and the side of the left straightening component 3 away from the right straightening component 4 is also provided with a cutting and blanking component. The working plane of the workbench 1 is a rectangular structure. The left straightening component 3 and the right straightening component 4 are respectively close to the left and right ends in the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com