Injection molding machine product process quality monitoring system and monitoring method

A technology for injection molding products and monitoring systems, which is applied in the process quality monitoring system and monitoring field of injection molding machines, and can solve the problems of product quality monitoring accuracy and low efficiency, slow production progress, low production efficiency, etc., and improve process quality management horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

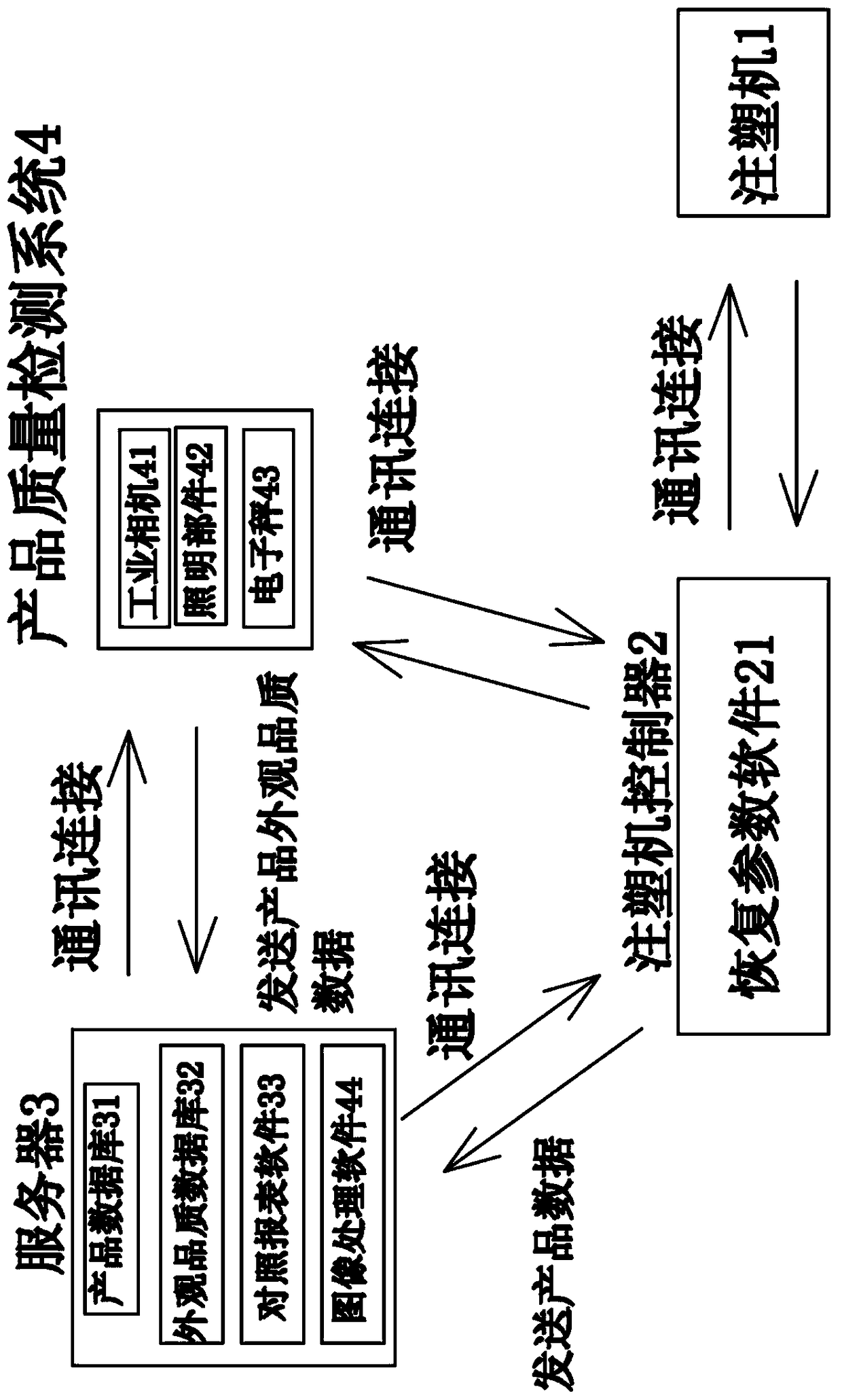

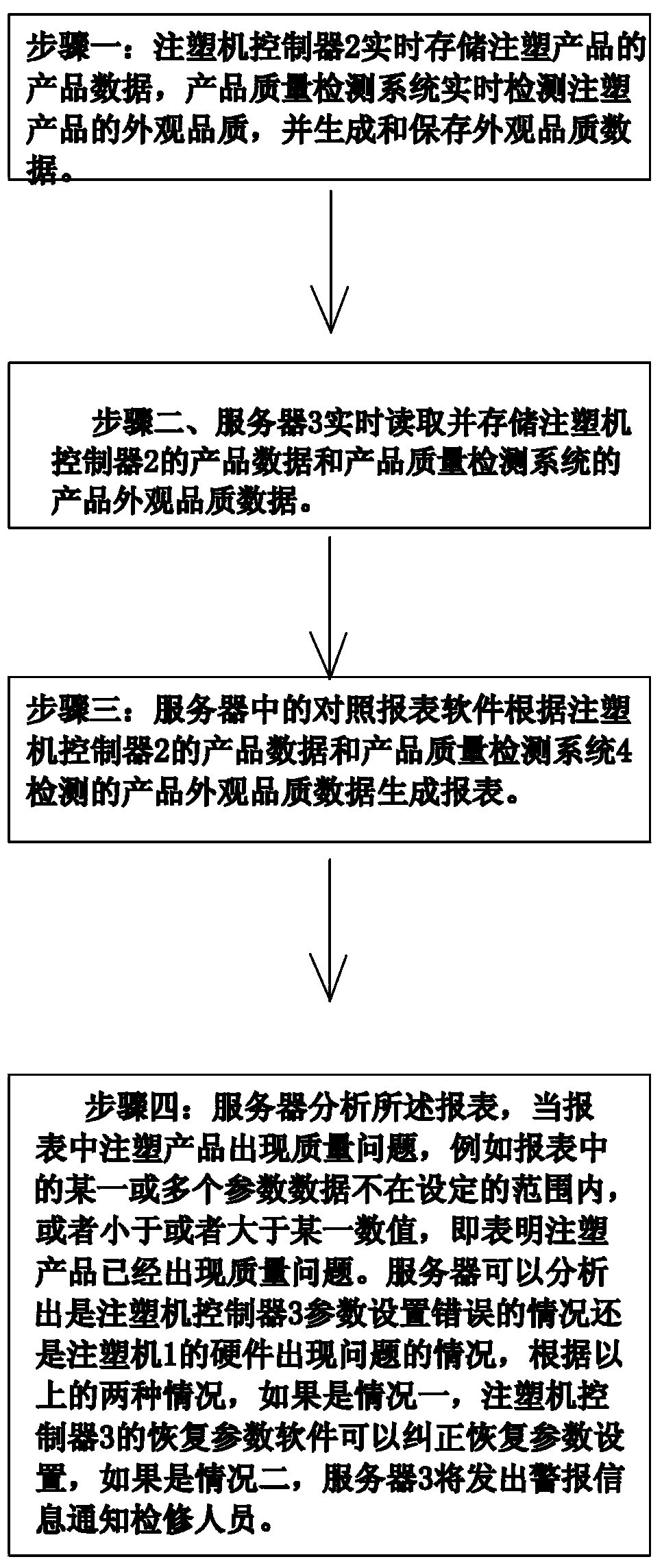

[0032] Embodiment one, such as Figure 1 to Figure 2 As shown, an injection molding machine product process quality monitoring system includes an injection molding machine 1 , an injection molding machine controller 2 , a server 3 and a product quality inspection system 4 .

[0033] The injection molding machine controller 2 communicates with the server 3, stores the product data of the injection molding product and the recovery parameter software 21, and transmits the product data of the injection molding product to the server 3 for storage in real time.

[0034] The product quality detection system 4 is communicated with the server 3, and is used to detect whether the product quality of each injection molding product is qualified. The product quality detection system 4 detects the appearance quality of the injection molding product in real time, and transmits the appearance quality data of the injection molding product to the Server 3 stores.

[0035] The server 3 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com