Wall replacement support device for reinforced concrete shear wall structure under high load action

A reinforced concrete and support device technology, which is applied to pillars, building structures, and on-site preparation of building components, etc., can solve the problems of narrow construction operation surface, rough structure of support devices, and large load on walls, so as to improve the construction efficiency. Efficiency, simple and clear structure, saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

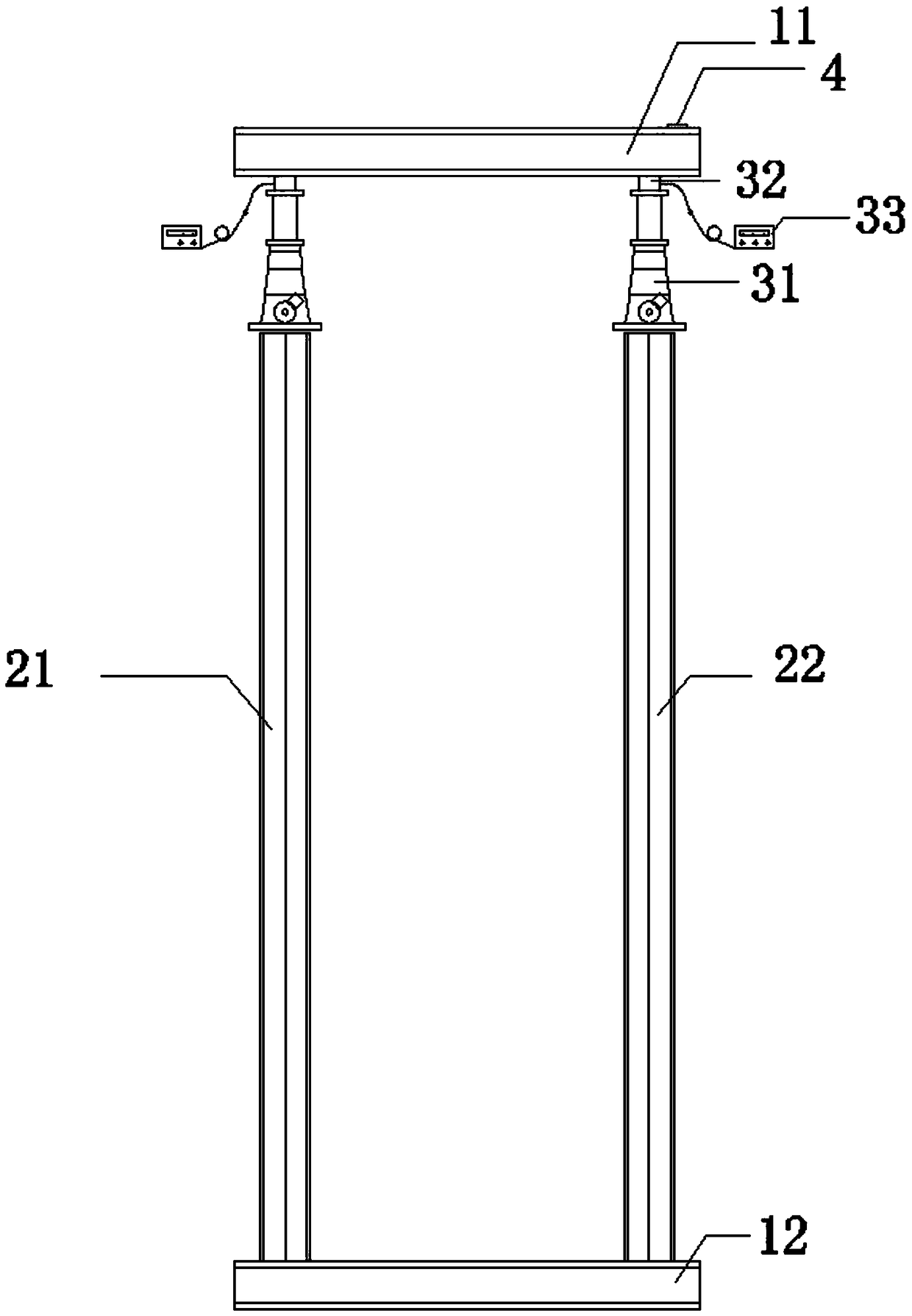

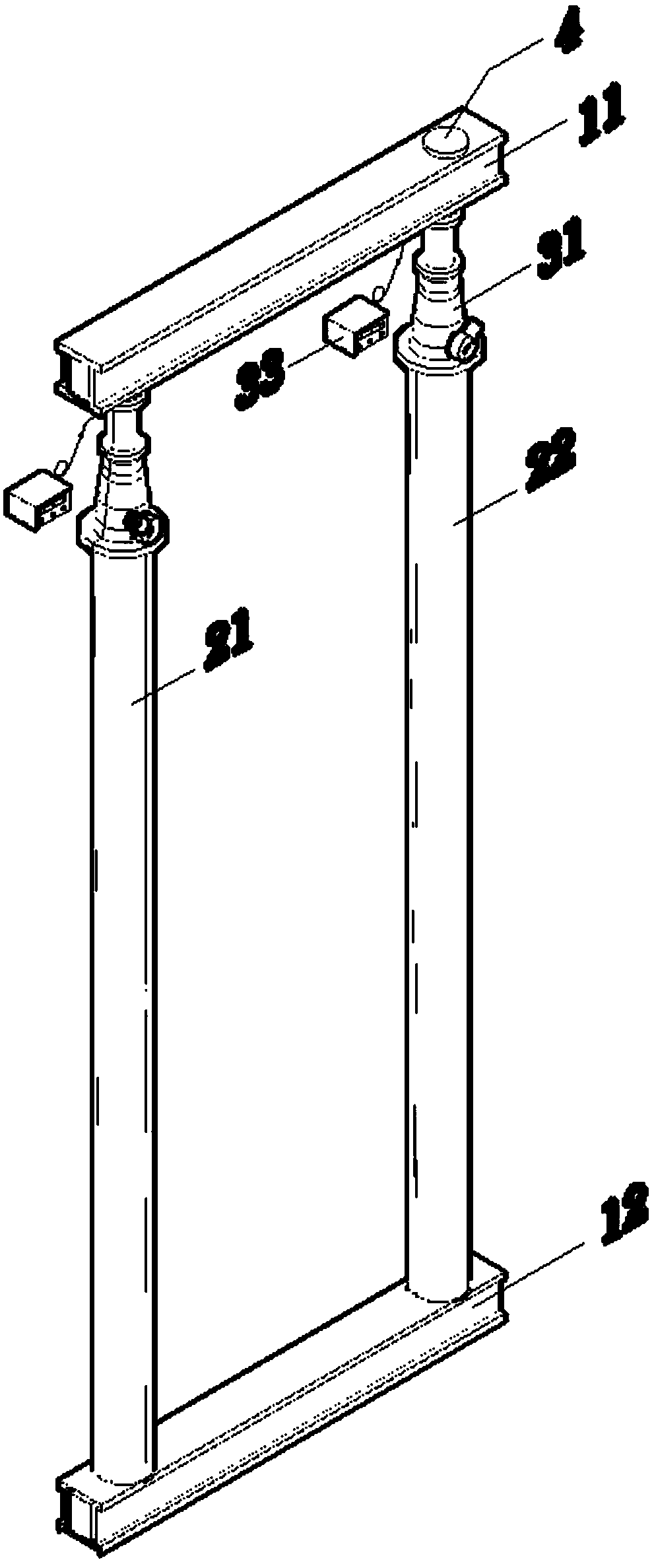

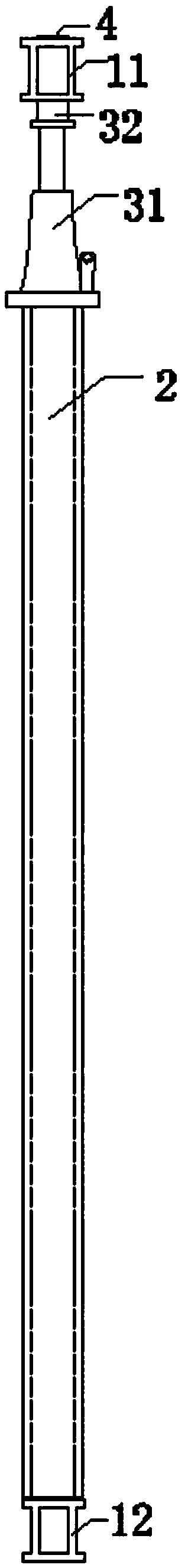

[0017] Refer to the attached figure 1 to attach Figure 5 The wall displacement supporting device of the reinforced concrete shear wall structure of the present invention under high load will be described in detail below.

[0018] The wall replacement supporting device of the reinforced concrete shear wall structure under high load of the present invention comprises a horizontal support system 1, a universal level 4, a vertical support system 2, a load application and monitoring device 3, and the horizontal support System 1 includes an upper beam 11 and a lower beam 12. The upper beam 11 and the lower beam 12 are arranged correspondingly up and down. The upper beam 11 and the lower beam 12 are respectively installed on the wall corresponding to the upper floor of the wall to be replaced and near the wall to be replaced. The position of the wall at the bottom of the floor, the vertical support system 2 includes a left vertical rod 21 and a right vertical rod 22, and the left v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com