Elastic detection device of large hook spring

A spring elasticity and detection device technology, which is applied in the direction of measuring device, elasticity test, machine/structural component test, etc., can solve the problem of the lack of feasible and effective detection means for the spring force of the hook spring, and achieve a small footprint , easy to control, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

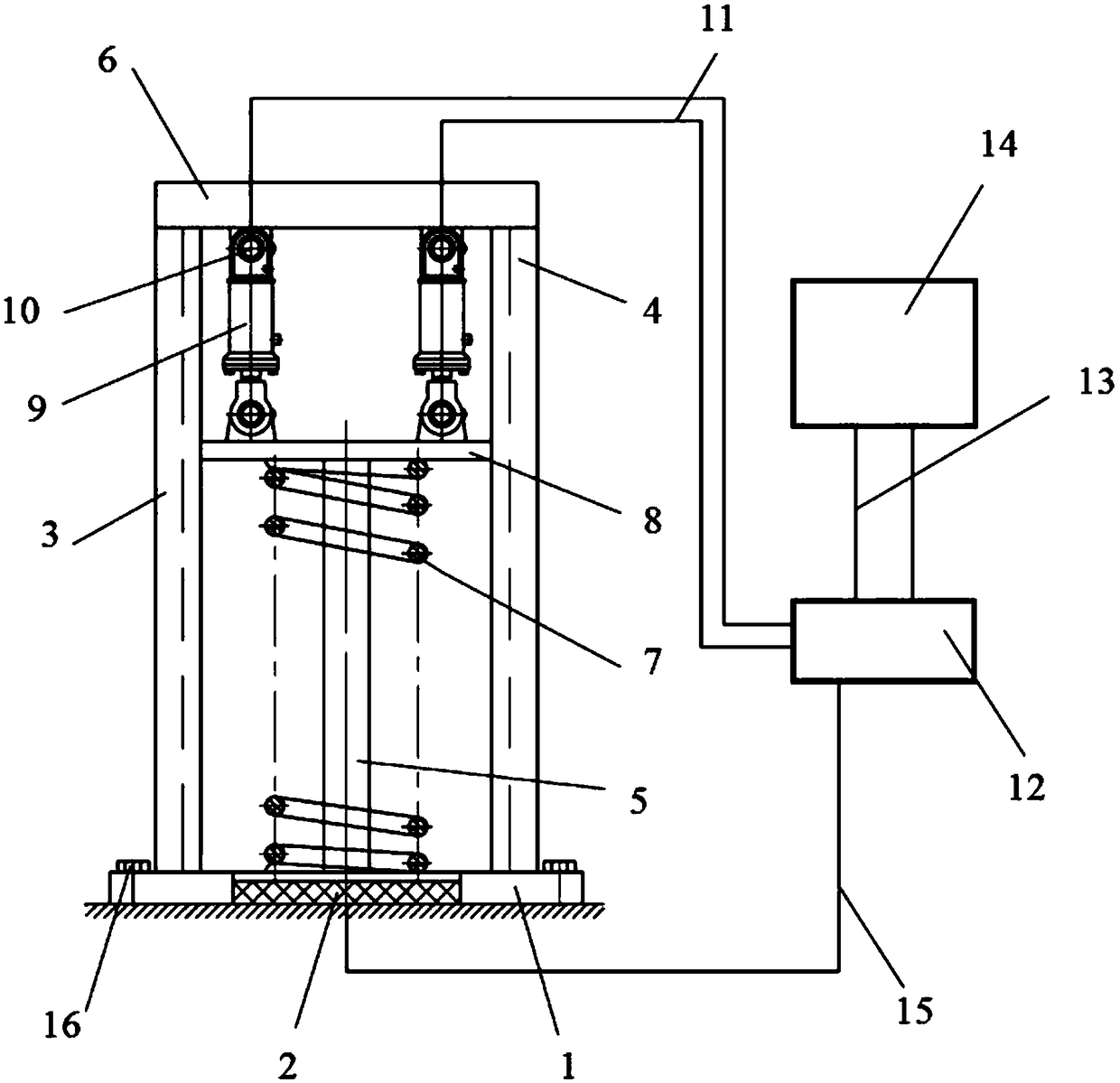

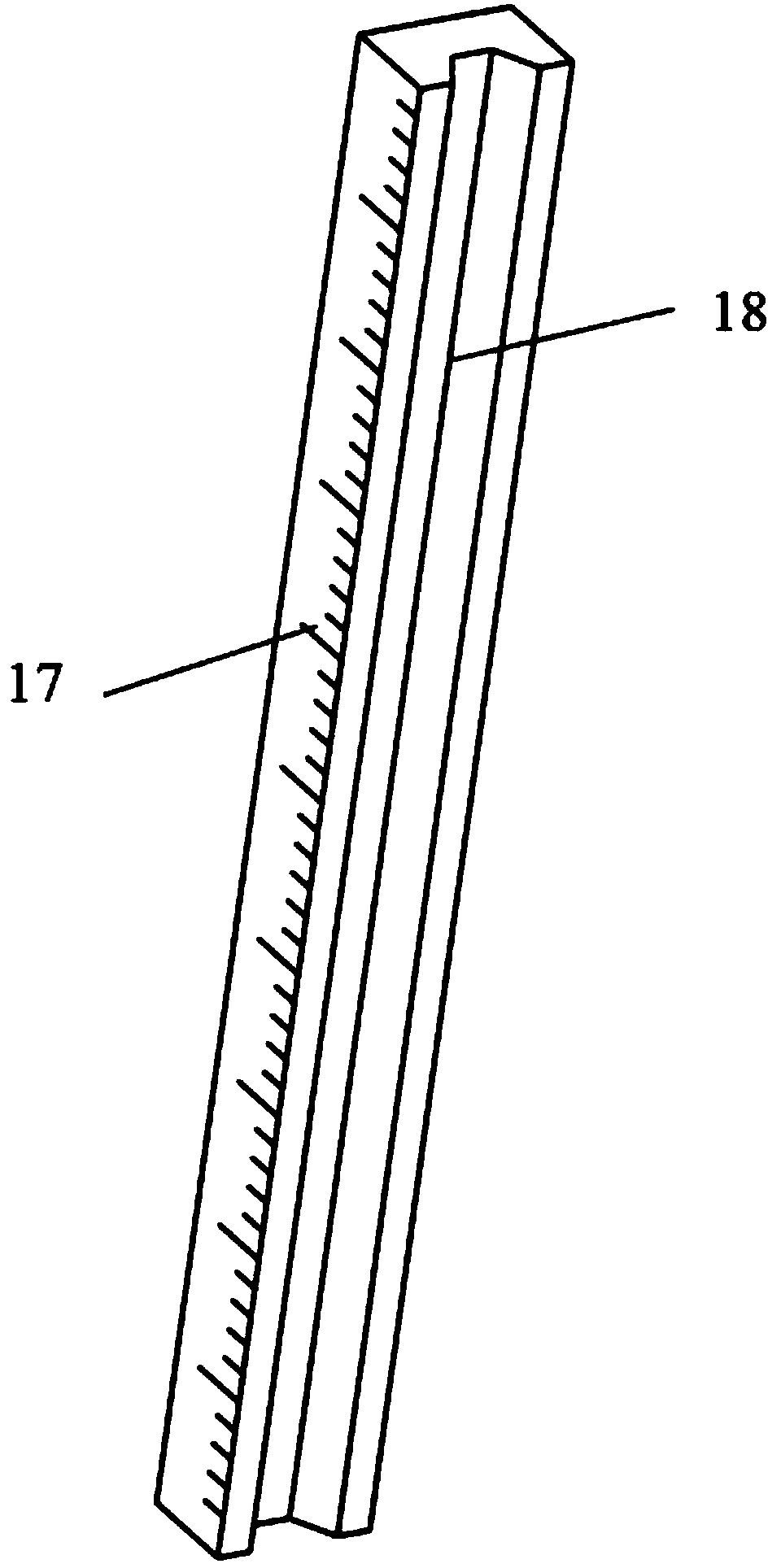

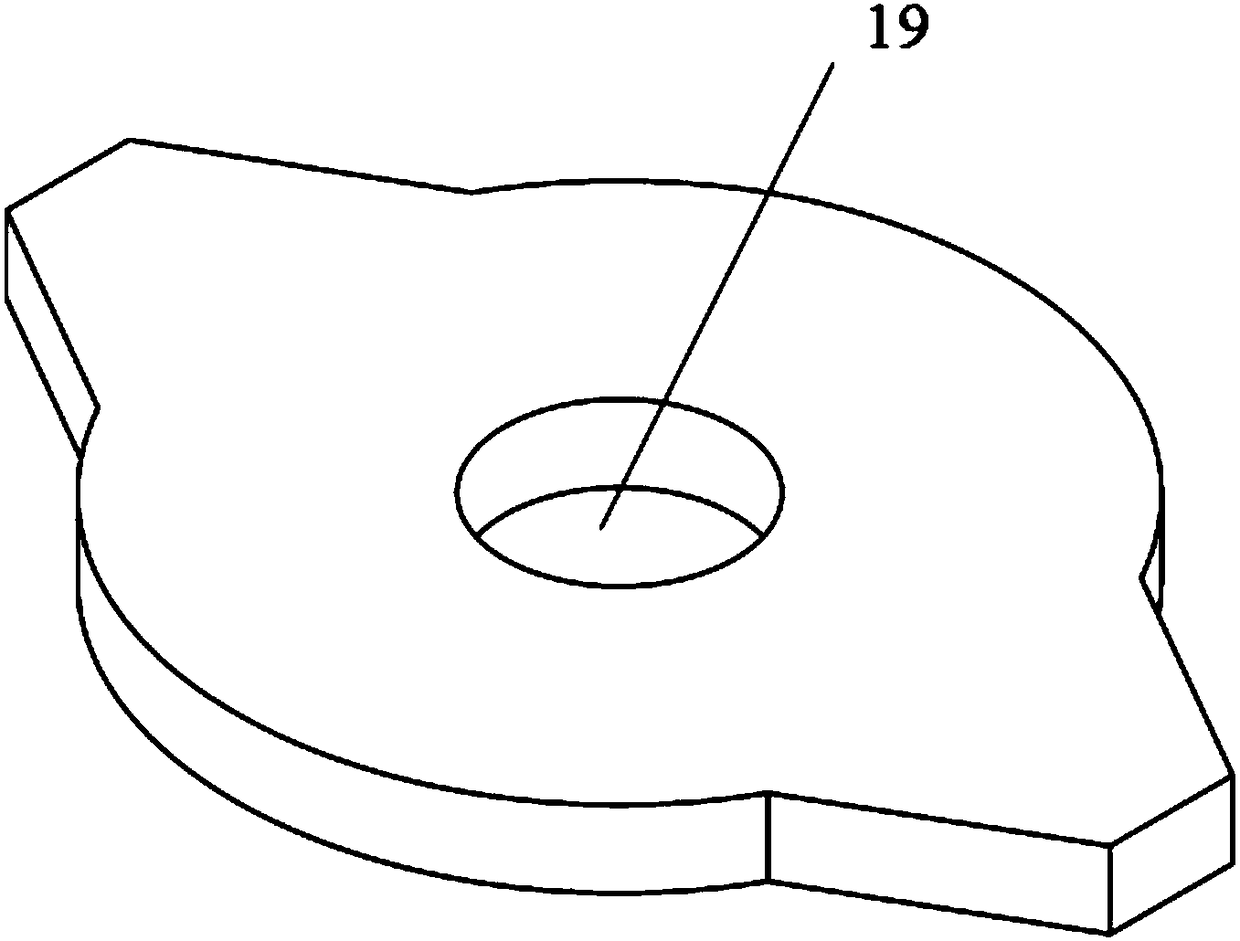

[0018] A kind of big hook spring elastic detection device provided by the invention, its structure is as follows Figure 1-3 As shown, it includes a fixing device, a pressure applying device, a control box 12 and a hydraulic station 14. The fixing device includes a base plate 1. The base plate 1 is fixed on the ground through bolts 16. The two ends of the base plate 1 are fixed with the first bracket 3 and the second bracket. Two brackets 4, the inner surfaces of the first bracket 3 and the second bracket 4 are provided with guide grooves 18, the surface is designed with a scale 17, a pressure sensor 2 is built in the upper surface of the bottom plate 1, and a guide rod 5 is affixed directly above the bottom plate 1 , the guide rod 5 is located directly above the pressure sensor 2, the guide rod 5 is covered with a spring 7, the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com