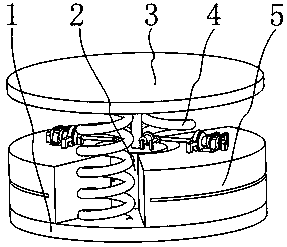

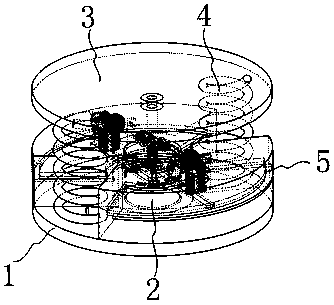

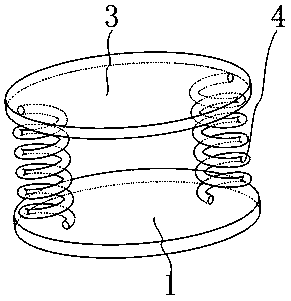

Vehicle shock absorber based on variable-friction-force damper

A technology of automobile shock absorber and friction force, which is applied in the direction of shock absorber, friction shock absorber, spring/shock absorber, etc., which can solve the problems of tire grip and track loss, uncontrollable spring rebound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0068] Specific embodiments: when people use the shock absorber designed by the present invention, during the vibration process, when the trigger plate 3 moves downward, the trigger plate 3 will drive the drive rod 6 to move downward through the bushing 50; Moving down will make the pressure delivered to the friction arc plate 49 by the drive rod 6 reach a stable state; that is, the friction force of the friction arc plate 49 to the corresponding first rack 7 reaches a steady state; while the drive rod 6 Moving down on the other hand will drive the corresponding first gear 8 to rotate; the rotation of the first gear 8 will drive the corresponding first rack 7 to move; 49 produces friction; the moving speed of the first rack 7 can be reduced by this friction force; that is, the downward movement speed of the driving rod 6 can be reduced by this friction force. That is, the shock absorption effect is achieved through the friction force. When the trigger plate 3 moves upward und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com